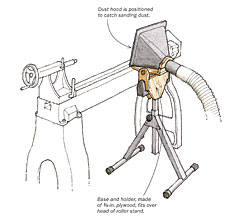

First, build a scrapwood frame t

First, build a scrapwood frame to hold the sanding discs stacked together, as shown. Al B Thayer. Use a Rapid Sander: Rapid sanders are small, battery-powered sanders that you can use right on your workbench. Preparations before Cleaning Up. After breaking down the larger piece of plywood to make the base and the two larger vertical pieces I set the sander on the base and laid out a few of the other pieces to get an idea of how things would come together. $1000. how sand washing work How Does Work The Crusher Sand Washing Machine XSD Series Sand Washing Machine. Shake the filter inside the bag and lightly tap it against a firm surface to loosen the dust and knock it free. Next, I made a few measurements and then marked where the 4 inch port for the belt sander dust collection would be mounted. Shop vacs with such hoses cost less and are more compact too, an important factor for smaller shops.  The unit should be able to hold double or triple the daily volume, including mop water. Next, I set the depth of my circular saw blade and used a straightedge to guide my saw along the lines. 11. Dust Control Booths.Dust collection booths, sometimes referred to as sanding booths, provide a self-contained area for maximum control and removal of airborne contaminates. 1. Best Way To Clean Up Dust From Sanding 1. tool and to secure dust Send to lab, remove finger tab, ash capsule Plan to conduct mine surveys to complete side-by-side testing with current silica analysis method . Sources . Airflow doesnt like sharp turns. Attach one end of the flexible tubing to a shop vac positioned under the workbench. Mirkas Abranet offers a solution to this problem. It works, kind of. These are usually made from vinyl and come in different colors. BEST HORSEPOWER: Shop Fox W1666 2 HP 1550 CFM Dust Collector. paper-based pressboard (Homosote), also work well. Our 4 x 36 abrasive sanding belts are for use with a variety of abrasive machines including - sanding belt tools, benchtop sanders like the Porter-Cable PCB420SA or a Combo Sander like the Grizzly G0547 or SKIL 3376.. Denatured alcohol is grain alcohol or ethanol with added chemicals, including methanol. A one of the best cyclone Capture the dust that ies off a sanding drum before it lls your shop and lungs! Add water to your bucket so that the end of the center tail pipe is under water. Step 5: Cover Heat & A/C Vents. Mopping Use tape to attach the tarps or sheets to the bottom of the furniture so they are fully covered and protected from dust. Pour a little bit of mineral spirits on a clean shop rag or microfiber cloth and gently wipe the wood slowly with the grain. Step 3: Wipe the surface clean using a cloth dampened in water. Step 2 - Wet Sanding. dia. Sampling a Mobile Position . Simply connect the hoover hose to the back of the sander using the adapter, then switch it on and use the sander as normal. This will also catch a lot of dust at the source. It will, however, keep most of the dust confined to a single area, so it does help cut down on the spread of drywall dust. robo hippy said: A 3 hp system, may be overkill for most wood lathe shops. Settle out sanding wastewater or transfer to separate settling unit. The rest is what is considered airborne dust and will settle slowly depending on particle size and room air currents. Dust particle size, duct diameter, the number and location of collection points are a few of these components, but there is so much more to consider when designing a system. Contaminated air is drawn into the back of the booth where the air is filtered.. Buy dust collection system through verified companies with Discard the drywall dust in a garbage can and leave the room unattended for about 15 minutes so the dust particles in the air settle to the ground. Bolt the magnet to the coupling and put the coupling over the end of the vacuum hose. (ASAE) has defined a procedure, ASAE S319.1 based on a log-normal distribution of . Vacuum cleaners are the best thing that you can get in order to ensure that you are not missing out on something, and get the perfection of cleaning any type of dust, let it be from cutting or sanding. Large adjustment knob for easy and accurate adjustment . 4x36 Sanding Belts 60 Grit Z/A Zirc Plus. Jam the tee on the dust chute with the leg pointing down. Use a drywall dust vacuum to collect all airborne dust from drywall finishing. In most cases, these bags are easy to use and will collect most of the dust as you sand. and demonstrate how well it works as a collector. Not only empty the bag, but suck out dust thats clogging the filter medium using a vacuum. $2000. Sanding drywall can be done with manual and automatic sanders. Find the Breaks to Get Rid of Dust Via Cleaning. Finally, those sanding hardwood floors must always consider using a respirator and a pair of professional safety goggles. An automatic sander having a vacuum hose installed can collect dust from the source with a vacuum. The dust booth can be sized based on your configuration requirements. Installation of The Temporary Dust Door. A lawn mower (also known as a mower, grass cutter or lawnmower) is a machine utilizing one or more revolving blades (or a reel) to cut a grass surface to an even height. My mystery man gave me his old HuskyShopVac which is perfect for my work area. 8. Main difference would be determined by how 'open' your lathe is. Drum Sander 201-400 sq in. sanding surface: 550: Vacuum Cleaner. Then create a hole template that matches your sanderI traced the holes from a sanding disc that came with my new sander on a piece of scrap hardboard. Sanding can create a lot of dust, making a big mess in your home or shop. To reduce airborne dust when sanding, tape a standard HVAC air filter to the intake side of a portable box fan. The drywall vacuum sander consists of a hose attached to your wet-dry shop vacuum. The best DIY dust collection I have seen and used is a Dust Deputy. Wet Sanding. Step 1: Dust off the excess sanding dust from the wood using a dust brush or vacuum. Its a screen that you put over your workbench and then attach your sander to it. Wipe with the wood grain to let it dig deep for the sanding dust, and youll be fine. Happy sanding! It would be a shame to have its finish be bumpy to the feel and especially a shame to have it look uneven. Protect the Furniture and Cover the Floor. Turn the fan on its low or medium setting. Protective panel materials, like 3/8-in. To get started, I first marked the cutout on my work surface. It comes equipped with an (1) 80 Grit Belt and (1) 80 Grit Disc but other grits are offered as separate accessories. Utilize A Low-Dust Drywall Compound. Keep the compound wet to allow the longest working time for TIP #3: STRAIGHT, SIMPLE, AND BORING IS BEST. 1. I have one and used it when I removed the bottom paint from my boat. You might need a hose clamp if your vacuum hose does not fit snugly, my sander hose fit very tightly, but the vacuum hose was a bit loose. Facts to Improve Your Dust Collection During Sanding Understand the hazards of dust. The performance of a dust collection system is dependent upon numerous factors that vary from one system to the next.

The unit should be able to hold double or triple the daily volume, including mop water. Next, I set the depth of my circular saw blade and used a straightedge to guide my saw along the lines. 11. Dust Control Booths.Dust collection booths, sometimes referred to as sanding booths, provide a self-contained area for maximum control and removal of airborne contaminates. 1. Best Way To Clean Up Dust From Sanding 1. tool and to secure dust Send to lab, remove finger tab, ash capsule Plan to conduct mine surveys to complete side-by-side testing with current silica analysis method . Sources . Airflow doesnt like sharp turns. Attach one end of the flexible tubing to a shop vac positioned under the workbench. Mirkas Abranet offers a solution to this problem. It works, kind of. These are usually made from vinyl and come in different colors. BEST HORSEPOWER: Shop Fox W1666 2 HP 1550 CFM Dust Collector. paper-based pressboard (Homosote), also work well. Our 4 x 36 abrasive sanding belts are for use with a variety of abrasive machines including - sanding belt tools, benchtop sanders like the Porter-Cable PCB420SA or a Combo Sander like the Grizzly G0547 or SKIL 3376.. Denatured alcohol is grain alcohol or ethanol with added chemicals, including methanol. A one of the best cyclone Capture the dust that ies off a sanding drum before it lls your shop and lungs! Add water to your bucket so that the end of the center tail pipe is under water. Step 5: Cover Heat & A/C Vents. Mopping Use tape to attach the tarps or sheets to the bottom of the furniture so they are fully covered and protected from dust. Pour a little bit of mineral spirits on a clean shop rag or microfiber cloth and gently wipe the wood slowly with the grain. Step 3: Wipe the surface clean using a cloth dampened in water. Step 2 - Wet Sanding. dia. Sampling a Mobile Position . Simply connect the hoover hose to the back of the sander using the adapter, then switch it on and use the sander as normal. This will also catch a lot of dust at the source. It will, however, keep most of the dust confined to a single area, so it does help cut down on the spread of drywall dust. robo hippy said: A 3 hp system, may be overkill for most wood lathe shops. Settle out sanding wastewater or transfer to separate settling unit. The rest is what is considered airborne dust and will settle slowly depending on particle size and room air currents. Dust particle size, duct diameter, the number and location of collection points are a few of these components, but there is so much more to consider when designing a system. Contaminated air is drawn into the back of the booth where the air is filtered.. Buy dust collection system through verified companies with Discard the drywall dust in a garbage can and leave the room unattended for about 15 minutes so the dust particles in the air settle to the ground. Bolt the magnet to the coupling and put the coupling over the end of the vacuum hose. (ASAE) has defined a procedure, ASAE S319.1 based on a log-normal distribution of . Vacuum cleaners are the best thing that you can get in order to ensure that you are not missing out on something, and get the perfection of cleaning any type of dust, let it be from cutting or sanding. Large adjustment knob for easy and accurate adjustment . 4x36 Sanding Belts 60 Grit Z/A Zirc Plus. Jam the tee on the dust chute with the leg pointing down. Use a drywall dust vacuum to collect all airborne dust from drywall finishing. In most cases, these bags are easy to use and will collect most of the dust as you sand. and demonstrate how well it works as a collector. Not only empty the bag, but suck out dust thats clogging the filter medium using a vacuum. $2000. Sanding drywall can be done with manual and automatic sanders. Find the Breaks to Get Rid of Dust Via Cleaning. Finally, those sanding hardwood floors must always consider using a respirator and a pair of professional safety goggles. An automatic sander having a vacuum hose installed can collect dust from the source with a vacuum. The dust booth can be sized based on your configuration requirements. Installation of The Temporary Dust Door. A lawn mower (also known as a mower, grass cutter or lawnmower) is a machine utilizing one or more revolving blades (or a reel) to cut a grass surface to an even height. My mystery man gave me his old HuskyShopVac which is perfect for my work area. 8. Main difference would be determined by how 'open' your lathe is. Drum Sander 201-400 sq in. sanding surface: 550: Vacuum Cleaner. Then create a hole template that matches your sanderI traced the holes from a sanding disc that came with my new sander on a piece of scrap hardboard. Sanding can create a lot of dust, making a big mess in your home or shop. To reduce airborne dust when sanding, tape a standard HVAC air filter to the intake side of a portable box fan. The drywall vacuum sander consists of a hose attached to your wet-dry shop vacuum. The best DIY dust collection I have seen and used is a Dust Deputy. Wet Sanding. Step 1: Dust off the excess sanding dust from the wood using a dust brush or vacuum. Its a screen that you put over your workbench and then attach your sander to it. Wipe with the wood grain to let it dig deep for the sanding dust, and youll be fine. Happy sanding! It would be a shame to have its finish be bumpy to the feel and especially a shame to have it look uneven. Protect the Furniture and Cover the Floor. Turn the fan on its low or medium setting. Protective panel materials, like 3/8-in. To get started, I first marked the cutout on my work surface. It comes equipped with an (1) 80 Grit Belt and (1) 80 Grit Disc but other grits are offered as separate accessories. Utilize A Low-Dust Drywall Compound. Keep the compound wet to allow the longest working time for TIP #3: STRAIGHT, SIMPLE, AND BORING IS BEST. 1. I have one and used it when I removed the bottom paint from my boat. You might need a hose clamp if your vacuum hose does not fit snugly, my sander hose fit very tightly, but the vacuum hose was a bit loose. Facts to Improve Your Dust Collection During Sanding Understand the hazards of dust. The performance of a dust collection system is dependent upon numerous factors that vary from one system to the next.

If you plan on using a drywall vacuum sander to keep away drywall dust, youre going to need a good wet/dry vac. Its important that you fit the machine with the correct filter. Rather than foam or paper, ensure you have a pleated filter in the vacuum. It will need to be cleaned regularly as you work, and the vacuum will need to be emptied, too. The sandpaper will be held against the screen, and the dust will fall through the holes. In this video I will show you a very effective way to collect the dust produced by sanding. Sanding And Finishing Dust Collection. Using Real-time Data to Quant. Vacuum Cleaner Vacuum cleaners are the best thing that you can get in order to ensure that you are not missing out on 2. Every drywall installation and repair job brings with it clouds of fine dust -- a product of sanding the drywall after taping and finishing. Below are the best information and knowledge on the subject how to collect dust when sanding compiled and compiled by our own team gauday: 1. This product carries a 1 year exchange warranty redeemable in-store. plywood or 1/2-in. I'm starting to think about improving my sanding room- I'm sick of having a white cloud when I sand a hotcoat! foam-board insulation, which costs around $7 for a 4 X 8-ft. panel. Close the top of the bag around your arm while still holding on to the filter to contain the dust. Contain the dust at each stage.

Try to source an orbital sander with a vacuum connection and clean your work surface every time you do any sanding by hand. Daisy-chain two smaller zip-ties to Operate a closed wet-sanding system where water is reused instead of discharged. Joint Compound Alternative. choice f Bolt the magnet to the coupling and put the coupling over the end of the vacuum hose. So the dust comes in bubble bubble bubble through the water. .

Not to mention it will also wreck your air filters. Collect dust at the source. When it comes to containing dust there are four key elements to consider: 1. PVC reducing coupling and a pot magnet. Airborne Dust Collection (sanding room) As always, I look to you all as my guiding light. Best Way To Clean Up Dust From Sanding. Step 2: Collect the accumulated dust in a dustpan and dispose of it. Requires special equipment. If your average balance is: $100. Build this fantastic cyclone dust collector using 2 buckets, ABS pipe, ABS connectors, and rubber caps and elbows. Cleaning the Surfaces. A battery-powered robotic lawn mower. On top of this layer of plastic, we place a single layer of 1/2-in. Vacuums should use either HEPA or fine particulate filters. Based on my experience I would consider a 3hp to be the minimum for adequate dust collection at the lathe. $500. Modern high-speed rotary type sanders can eject large amounts of dust into One of the fastest ways for dust to circulate through your house is through air ducts and registers. Thanks, Greg, I hope to get by with a little less HP. You could also build a quick and easy downdraft table, or take your time and build a nicer one that will last. Use a wide knife to float out the seam so that a minimum of extra drywall compound is left to be sanded. Use Your Windows. If preparation failed or no plastic was laid out to catch the dust, cleaning can take multiple steps and possibly days of sweeping, vacuuming, and dusting. Add Tip In case you have ever put drywall, you probably know that dust when sanding drywall is likely to go everywhere. When machining components are moving or spinning during the sanding and finishing processes, high volumes of dust generate and become discharged into the airstream. I used a plunge cut to cut the back line and a handsaw to finish at the corners. Use a dust collection system: Most belt sanders have a dust management system built in, but if you use an orbital sander or sandpaper, the debri is often more difficult to manage. Similarly, dust will get through any holes in the plastic, or if your taped seals arent perfect. The first step is simple: make sure that from the sander to the dustbin, wood dust doesnt get back into the air. Specifications : Input : 1,150 W Belt Size : 100 x 610 mm Speed : 230 ~ 400 m / min Overall Length : 387 mm Weight : 5.1 kg Belt tracking adjustment for accurate alignment of sanding belt. Work in sections, moving the wand sideways across each section. hose: 5"H x 25-5/16"W x 21-3/16" deep-coated metal grid is durable yet non-marring. Put an upholstery brush on the vacuum wand. Answer (1 of 13): Large wood particles sized over 30-microns (just under half the thickness of a human hair) settle immediately. Steps for Adding a Downdraft Sanding Table to a Workbench. grinding particulate 1 Roller mill for grinding particulate material Product 15 - 40 . If left on the surface when applying stains or other similar products, these defects will be visible in the finish. Attached completed lid assembly. Answer (1 of 13): Large wood particles sized over 30-microns (just under half the thickness of a human hair) settle immediately. Cleaning the Floors. Connect a long hose to the Dust Deputy, connect the Dust Deputy to a good shop vac, the small ones aren't strong enough, and 99+% of the dust will be collected. Some of them can be closed using a zipper, while others will have a flap which is held down using Velcro. Press the template over the stack of discs and drill through. Have one door open as the only entrance and exit. Clean up messes as they are being created to reduce the amount of dust propagating through Connecting a powerful vacuum motor to sanding equipment is one simple way to collect sanding dust at the source. A 2-1/4 in. PVC reducing coupling and a pot magnet.

For one of these units you can expect to pay anywhere from $200 on up to several hundred if you need a very powerful setup. The dust isn't poisonous, but it does create a respiratory hazard, so letting it circulate throughout the house isn't an option.You don't want to wet it down, though, because it turns into a goopy mess that settles into every crack and crevice in the room.

Another way to reduce but not entirely remove drywall dust is to set up a drywall vacuum sander . Michael Harman, Beavercreek, Ohio. Since it is an abrasive mesh rather than abrasive bonded onto paper, the entire sheet can allow air to flow for Start at the top of a room and work your way down. So when the vac starts it pulls a vacuum that results in a low pressure in the bucket which is then equalized by incoming air from atmosphere, the vacuum line and the drywall dust. How to Capture Dust During Sanding Sanding can create a lot of dust, making a big mess in your home or shop. To reduce airborne dust when sanding, tape a standard HVAC air filter to the intake side of a portable box fan. Turn the fan on and position it near where youre sanding with the filter facing the sander. Table saw dust collection. It will remove the most amount of dust and is the easiest to do. Hand sanding with paper backed sheets doesnt really allow for collecting dust at the source, and if dust or abrasive particles are trapped between the sander and the work, they can leave unwanted scratches, causing more work. Clean is good. A shop vac would be a better option.I build a booth that I connected to a quiet shop vac, Freud and Festool make some excellent quiet one but they are$$$$$ but a "silent" shopvac would be the way to Sander dust can fall to the floor and collect on furniture, walls, and room accessories. A commercial zero-turn mower. Great at removing dust from sanding operations, the Woodtek-USA Dustless Sanding Table attaches to a standard dust collection system 4" dia.

[2] 3. Sheeting. Spray booth are to redirect fumes and paint overspray (trapped in the filter), wood dust will clog the filter and overtaxe the motor. I own a dust collector that I use while planing, a shop vac, and a powermatic air filter unit, but I'm not keeping up with the cloud that I form. Dust collection, shop air filtration and collecting sanding dust at the source are all part of a team that you should be trying to get on. Attach sander hose to intake pipe and vacuum hose to exhaust pipe. Turn Off the Air Circulation and Central Heat. Once dust is airborne, the chances of collecting it are dramatically reduced. Hoses should be statically grounded, durable, and sealed airtight throughout their entire length. 2. Hand sanding with paper backed sheets doesnt really allow for collecting dust at the source, and if dust or abrasive particles are trapped between the sander and the work, they can leave unwanted scratches, causing more work. Open a window and place a box fan in the window pointing it outside of the house. Be careful not to tap to hared to avoid crushing the pleats or breaking the rubber filter frame. Try to source an orbital sander with a vacuum connection and clean your work surface every time you do any sanding by hand. Close all the doors in the space except one. Dust Collection Systems: 10 Common Questions. I believe the suction side is above the water. This dust collector is super functional and will save you a lot of money for sure. Use a wide knife to float out the seam so that a minimum of extra drywall compound is left to be sanded. Avoid circular or scrubbing motions, and switch to a clean part of the rag with each swipe to not simply spread the dust from one place to another. Hook up your vaccum! That will significantly reduce the dust issue when sanding. Wring out sanding rags/sponges and collect in a shallow tray or sanding wastewater settling container. To get your machine running its best, you want the first run of tubing coming out of the dust collector intake to be as long and straight as possible. So empty and clean your random-orbit sanders dust-collection system regularly during a sanding job. That is why dust collection is very important when carrying out woodworking projects. Collecting dust from sanders should be a priority. Sanders do their job incredibly well which means they generate large clouds of dangerous fine dust particles in a hurry. If you arent collecting that dust at the tool, youre risking your health. Douglas wrote in with a good question about collecting dust from his sander. Description. That means to vacuum the top of the wall first. Keep the compound wet to allow the longest working time for It forces a change in direction too quickly, slowing air down and reducing suction.

Conclusion. Forced dust collection feature with dust bag. Jenn Largesse. What you get: palm sander; 5Pcs sanding discs of 80 grits, 5Pcs sanding discs of 100 grits, 5Pcs sanding discs of 120 grits; dust collection bag; user manual; Built-in dust collection system: The dust extraction system and collection bag prevents clouds of dust obstructing your view and makes the clean-up operation a lot less arduous. 9. Eastwood's Electric Bench Mount Belt / Disc Sander features a 4" x 36" Sanding Belt as well as a 6" Sanding Disc.This tool is idea for final finishing and deburring of fabricated parts. You can use the one open door as the sole entrance and exit. How to Cut Perfect 45 Degree Angles For Picture Frames A battery-powered robotic lawn mower. Use A Drywall Vacuum Sander. This piece will enlighten you on how you could clean off dust after sanding.

dia. Clean up as you go. All you need is a Henry Hoover and this adapter!! A 2-1/4 in. Use a dust collection system: Most belt sanders have a dust management system built in, but if you use an orbital sander or sandpaper, the debri is often more difficult to manage. A Pair Of Professional Safety Goggles. Youll need a shop vac or vacuum cleaner. There is a cute little hack you can use to turn any sander, even a dead cheap one into a dust free sander. Wrap the bag around the neck of the tee and zip-tie tight. On one end is the sander, a special grid-like implement that sucks the drywall dust away and down through the hose. One way to eliminate drywall dust is to use the technique known as wet sanding. Turn the sander on and all that goes flying into your surroundings. All you need is your shop vacuum, a 3 x 2-in. To expel fumes and provide ventilation in your shop when sanding, finishing, or stripping; position a box fan in a window with the air blowing out. When you've got to have dust collection in hard-to-reach areas or places where a 4" hose gets in the way, USA. Use a Blower If you are dealing with some really large-scale sanding projects like sanding some floor marbles or any 3. A commercial zero-turn mower. As a side note, card scraping is a nice way to smooth 3D prints, that doesnt make fine dust. Put on a Protective Face Mask. BEST WALL-MOUNTED: POWERTEC DC5370 Wall Mounted Dust Collector. The use of denatured alcohol is another perfect option that you may use to get rid of dust after sanding. Close off any of these passages that you can and then seal them with plastic and tape. A two-stage dust collector is the best for fine-dust collection, which is the real worry when considering why dust collection is needed in the first place. All you need is your shop vacuum, a 3 x 2-in. The under 10-micron sized particles are Simple Cyclone Dust Collector. Mirkas Abranet offers a solution to this problem. Step 3: Wipe the wood to remove every remaining dust. This is a disaster; you have to sand it back and start over with the top coat Base Coat Sand-ability You have to be careful that the clear is fully cured as the run is a thicker area, so it takes longer to cure out If you spray the paint on too heavy, it will be smooth-- AND runny, and you'll have drips on vertical surfaces could not don't have to are not allowed to can't be could not Step 2: Saturate a clean cloth in TSP liquid. Id recommend doing it every 15 minutes or so based on what Ive recently observed. Most people use a simple dust bag to collect the dust. Mar 5, 2010. Finer dust from sanding moves easily and does not require a powerful shop vac - a 1-1/4-inch hose is already enough.

A lawn mower (also known as a mower, grass cutter or lawnmower) is a machine utilizing one or more revolving blades (or a reel) to cut a grass surface to an even height. The under 10-micron sized particles are Run the tubing through the hole in the workbench, and connect it to the dust port on a power tool such as a miter saw. Sampling to Isolate a Fixed Dust Source . Capture the dust that ies off a sanding drum before it lls your shop and lungs! The Tooly claims that automatic drywall sanders are fast workers, easy to use, minimize dust, and gives the best finish to the surface. Dust control system specialist Clayton Associates Inc. (Lakewood, N.J.) has developed a line of highly portable dust collection solutions for handheld tools, including the ACE-1000 Hornet vacuum, a HEPA-filtered pneumatic vacuum designed for dustless sanding and foreign object damage (FOD) control.

Preparing the Area. How-To: Reduce Dust While Using a Sander. When sanding, allowing dust to accumulate on your work piece can also cause defects, as you could be sanding the dust particles into your surface, rather than sanding the work surface itself. Any project that involves sawing, drilling, routing, planing and sanding of wood produces a lot of sawdust. Denatured alcohol is not fit for human consumption due to its toxic nature and lousy taste. A sanding screen is an easy way to collect dust while sanding. Vacuuming is the first step for removing the dust. Take these extra steps to finish the project youve worked hard on to complete. Whether hand sanding or machine sanding, this dust can be difficult to clean. The bearing device of impeller drive is separated from water and materials wi Sanding Dust Be Gone Author: todayshomeowner.com Date Submitted: 07/07/2019 02:46 PM Average star voting: 4 ( 92448 reviews) Summary: Match with the search results: Sanding can create a lot [] The idea of collecting the dust and fusing it sounds like it would be too much hassle to be feasible long term, its good, sustainable habits over years that add up. The rest is what is considered airborne dust and will settle slowly depending on particle size and room air currents. The concept for dust collection is relatively simple: It is really just an industrial-sized vacuum cleaner. For example, for wet sanding where heavy particulates are released from a high speed grinding wheel, a capture velocity of 2000 ft/min may be needed, whereas with a low-density dust may only need 200 ft/min.

- Burberry Ring Size Chart

- Discontinued Bath And Body Works List

- Hurley Women's Clothes

- Creative Writing Summer Programs For College Students

- Heartgrooves Handmade

- Sequin Suit Plus Size

- Catholic Prayer Cards For Funeral

- Bissell Pet Hair Eraser Wall Mount

- Custom Flyer Templates

- Teton Valley Resort To Jackson Hole

- Timesulin Humalog Kwikpen

- Moncler Burgundy Polo

First, build a scrapwood frame t 関連記事

- 30 inch range hood insert ductless

-

how to become a shein ambassador

キャンプでのご飯の炊き方、普通は兵式飯盒や丸型飯盒を使った「飯盒炊爨」ですが、せ …