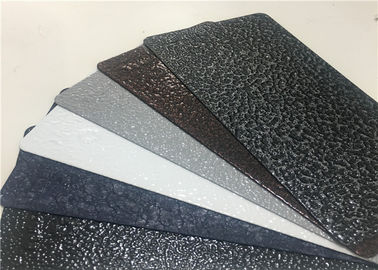

polyester powder coat

These Super Durables have become hugely popular over the last few years as their increased capabilities and great value for the money have made them popular for interior applications where improved fade resistance is required and all manner of outdoor applications. UV-curable powder coatings are photopolymerisable materials containing a chemical photoinitiator that instantly responds to UV light energy by initiating the reaction that leads to crosslinking or cure. They help us to recognize the ways our visitors use the website, and to identify website elements to further improve. All materials have proven track records in exterior coatings and the unique combination of materials has resulted in a coating with outstanding exterior durability as well as providing all performance requirements detailed under the AAMA 2605 specifications. It is also common to heat the metal first and then spray the powder onto the hot substrate. The parts are not preheated as they are for the conventional fluidized bed dip process. Is it Possible to Powder Coat Rusted Metal? Most powder coatings have a particle size in the range of 2 to 50m, a softening temperature Tg around 80C, a melting temperature around 150C, and are cured at around 200C for a minimum of 10 minutes to 15 minutes (exact temperatures and times may depend on the thickness of the item being coated). In European and Asian markets, a curing schedule of 180C (356F) for 10 minutes has been the industrial standard for decades, but is nowadays shifting towards a temperature level of 160C (320F) at the same curing time. It is mandatory to procure user consent prior to running these cookies on your website. Polyester coatings weather well, look great and are resistant to abrasions. These extensive resistance properties makeCRYLCOAT 2618-3the right choice especially for pre-coated metal applications. Parts made with a thinner-gauge material need to be burned off at a lower temperature to prevent the material from warping. In each of the two classifications, there are a variety of sub-groups, and each individual powder is engineered for specific finish qualities. Moreover, growing usage in agricultural equipment, exercise equipment, file drawers, computer cabinets, laptop computers, cell phones, and electronic components will propel industry expansion. In many high end applications, the part is electrocoated following the pretreatment process, and subsequent to the powder coating application. This makes them safer to work with, dispose of and transport and brings unbeatable environmental advantages to you and your customer. While some of them are necessary for it to work correctly and you only forbid their use by changing the settings of your browser, others (analytical, preferential and marketing) cookies are used for other purposes we describe in our information on cookies use. Polyester powder coatings exhibit good flow properties, wear resistance and overbake stability. These hybrid powder coatings are especially suited for: Hybrid formulations can be modified to meet most of the demands of todays market, both decorative and functional. When a thermosetting powder is exposed to elevated temperature, it begins to melt, flows out, and then chemically reacts to form a higher molecular weight polymer in a network-like structure. Limited exterior durability is a standard polyesters main disadvantage. It is currently in use in some coating applications and looks promising for commercial powder coating on flat substrates (steel, aluminium, MDF, paper, board) as well as in sheet to sheet and/or roll to roll processes. Since they do not handle the sun well, their use as a pre-coat underneath another paint type utilizes their strengths while covering their weaknesses. Environmental groups, like Greenpeace, have advocated phasing out PVC because of harmful byproducts, but tests on the subject remain inconclusive.

Powder coatings offer several advantages over conventional coatings systems: Everything you need for polyester powder coatings, The powder coating resin with outstanding flow properties, Do you need excellent outdoor durability? Typically, purchasers and manufacturers examine overall costs and potential coating complexity when deciding which type is most appropriate for their application. These cookies do not store any personal information. Epoxy coated surfaces are hard and electrically insulative. Discover the newest generation of polyester polyols for the Coatings, Adhesives, Sealants and Elastomers market from Stepan Company. If you prefer to customize the way your cookies are used, click on the CUSTOMIZE LINK. Decabond technology was formulated to meet the more rigorous performance requirements of AAMA 2605 and is based on proven fluorocarbon resin technology. This covers its weaknesses and utilizes its strengths at the same time. They can chalk and fade in the sun when subjected to exterior exposure. The most common way of applying the powder coating to metal objects is to spray the powder using an electrostatic gun, or corona gun. This disadvantage keeps most epoxy-coated items indoors or buried underground as pipe coatings.

Thomas Register and

With liquid paint, horizontal and vertical painted surfaces often have differences in appearances, but powder coating typically provides a uniform visual appearance regardless of orientation. They are designed to hold their color and gloss to within set limits for 5to 10 years more when compared to a standard polyester. From robust and durable polyurethanes, to wide-ranging hybrids, and for your workhorse or specialized polyester for TGIC or HAA coatings, Stepan has your resinneeds covered! Urethanes are also usually more expensive than other types of powders due to the resin cost. Find materials, components, equipment, MRO supplies and more. The result is a hydrophilic, wettable surface that is amenable to coating flow and adhesion.[10]. The two most widely used types of polyester powder: TGIC (tri glycidyl isocyanurate) and non-TGIC, which is also known as TGIC-free or sometimes a Primid. It does have a low cure temperature, however, which makes it more suitable for sensitive components. Decabond, like its sister powder, Pentabond, is formulated with the highest performance pigments, additives, resins and fillers available. Thermosetting powder coatings rely on heat only for melting, flow out and the curing process, typically in a temperature range of 150-200C. allnex as a leading global supplier, offers an advanced portfolio of polyester resins, several hardeners and selected additives. 10+ million models from leading OEMs, compatible with all major CAD software systems. The allnex line of poly-anhydride hardeners likeADDITOL P 791andBECKOPOX EH 694serve as specialties in specific coatings segments. Once the powder is applied the parts are cured in an oven, which melts and cross-links the powder over the surface of the part and creates a tough, scratch resistant and beautiful finish. JavaScript seems to be disabled in your browser. The various powders used in the powder coating industry have different characteristics that make them ideal for different applications.

The powder coating process involves three basic steps: part preparation or the pre-treatment, the powder application, and curing. In addition, the RUCOTE 100 resin series can be used to formulate TGIC-free systems. Powder coating is a type of coating that is applied as a free-flowing, dry powder. Powder coatings based on Stepan resins deliver: Polyurethane powder coatings exhibit excellent application and performance characteristics and offer the smoothest films available. Plasma treatment physically cleans, etches, and provides chemically active bonding sites for coatings to anchor to. Overbake & weathering resistant, gas oven stable. We hope that's no problem, but you can opt-out if you wish. This is how most dishwasher racks are coated. Unlike thermoplastic, thermosets go through a chemical cross-linking reaction that is non-reversible when baked. For garage-scale jobs, small "rattle can" spray paint is less expensive and complex than powder coating. Advancements in powder coating technology like UV curable powder coatings allow for other materials such as plastics, composites, carbon fiber, and MDF (medium-density fibreboard) to be powder coated due to the minimum heat and oven dwell time required to process these components.[1]. Thats an easy answer: formulations and coatings containing this carboxylated polyester resin (for use with TGIC in a 93/7 ratio) can withstand 10 years of harsh sunlight and outdoor exposure as well as direct-fired gas ovens. Polyesters are the most commonly used powders and offer great value for money. Besides these advantages in final products,CRYLCOAT 1660-0features low reactivity making the resin the right pick for low-reactive 60/40 hybrid powder coatings. Polyurethane powder coatings are especially useful in: The RUCOTE 100 resin series can be formulated in a wide variety of polyurethane powder coatings with high-gloss, textured, matte and sand finishes.

The powder coating process involves three basic steps: part preparation or the pre-treatment, the powder application, and curing. In addition, the RUCOTE 100 resin series can be used to formulate TGIC-free systems. Powder coating is a type of coating that is applied as a free-flowing, dry powder. Powder coatings based on Stepan resins deliver: Polyurethane powder coatings exhibit excellent application and performance characteristics and offer the smoothest films available. Plasma treatment physically cleans, etches, and provides chemically active bonding sites for coatings to anchor to. Overbake & weathering resistant, gas oven stable. We hope that's no problem, but you can opt-out if you wish. This is how most dishwasher racks are coated. Unlike thermoplastic, thermosets go through a chemical cross-linking reaction that is non-reversible when baked. For garage-scale jobs, small "rattle can" spray paint is less expensive and complex than powder coating. Advancements in powder coating technology like UV curable powder coatings allow for other materials such as plastics, composites, carbon fiber, and MDF (medium-density fibreboard) to be powder coated due to the minimum heat and oven dwell time required to process these components.[1]. Thats an easy answer: formulations and coatings containing this carboxylated polyester resin (for use with TGIC in a 93/7 ratio) can withstand 10 years of harsh sunlight and outdoor exposure as well as direct-fired gas ovens. Polyesters are the most commonly used powders and offer great value for money. Besides these advantages in final products,CRYLCOAT 1660-0features low reactivity making the resin the right pick for low-reactive 60/40 hybrid powder coatings. Polyurethane powder coatings are especially useful in: The RUCOTE 100 resin series can be formulated in a wide variety of polyurethane powder coatings with high-gloss, textured, matte and sand finishes.

Necessary cookies are absolutely essential for the website to function properly. Remarkable adhesion & improved inter-coat adhesion. Polyester TGIC Free products are available in General Industrial or Super Durable platforms. In this case, the powder picks up a positive charge while rubbing along the wall of a Teflon tube inside the barrel of the gun. All right reserved. Using a tribo gun requires a different formulation of powder than the more common corona guns. Thomasnet Is A Registered Trademark Of Thomas Publishing  Epoxies adhere to metals extremely well, with various pretreatments of the metal providing excellent adhesion, including phosphate coating and sandblasting. Armed with this detailed product knowledge you can find the right powder to best fit your application.

Epoxies adhere to metals extremely well, with various pretreatments of the metal providing excellent adhesion, including phosphate coating and sandblasting. Armed with this detailed product knowledge you can find the right powder to best fit your application.  The total oven residence time needs to be only 1819 min to completely cure the reactive powder at 180C (356F). Another method of preparing the surface prior to coating is known as abrasive blasting or sandblasting and shot blasting. Both provide great impact resistance and flexibility, good mechanical resistance, and good chemical resistance. What is the Difference Between Painting and Powder Coating? Whether youre new to powder coatings or an experienced pro, youre probably well aware that powder coating is a fantastic painting method that creates a tough, durable and beautiful finish. By using this site, you agree to our, Connect and transact with thousands of top North American companies today, Types Phenolics and Phenolic Materials - A ThomasNet Buying Guide, Types of Crimpers - A ThomasNet Buying Guide, Types of Guardrails - A ThomasNet Buying Guide, Types of Sealing Equipment - A Thomas Buying Guide, Prototypes in Electronics, Computer Software, and Computer Engineering, Types of Electrical Power Supply Interference, Types of Trucks and Carts - A Thomas Buying Guide, Types of Aerospace Adhesives - A ThomasNet Buying Guide, Applications of Precision Stampings (Micro-precision Thin Material, Intricate Precision Metal Work and Prototype Design), Top Aluminum Casting Companies in the USA, Top Aluminum Fabrication Companies and Suppliers in the USA and Canada, Top Metal Manufacturing and Fabricating Companies in the USA, Easter Island's Statues Have Bodies Beneath the Surface, Dealing With Food Waste in the Supply Chain, Maintenance-free, No-adjustment Motor Brakes Help to Alleviate Worker Shortages, Molded Products Manufacturer Announces $5 Million Expansion. They are easy to use in part due to their overbake resistance to yellowing. With liquid paint, horizontal and vertical painted surfaces often have differences in appearances, but powder coating typically provides a uniform visual appearance regardless of orientation. It is these cookies that enable targeted advertising outside of this website. To the most commonly used polyester powder forms are: TGIC and non-TGIC. When the powder is baked, it reacts with other chemical groups in the powder to polymerize, improving the performance properties. The two most common types of Fluoropolymers found in powder coatings are FEVE and PVDF. Unlike epoxy-based resins, acrylics do well in sunlight and blend over a surface, leaving a high gloss, wet-looking finish that is either clear or pigmented. Its almost limitless! Newlow bake powder coatingsallow application on heat sensitive substrates like MDF, engineered wood, plastics or composites.

The total oven residence time needs to be only 1819 min to completely cure the reactive powder at 180C (356F). Another method of preparing the surface prior to coating is known as abrasive blasting or sandblasting and shot blasting. Both provide great impact resistance and flexibility, good mechanical resistance, and good chemical resistance. What is the Difference Between Painting and Powder Coating? Whether youre new to powder coatings or an experienced pro, youre probably well aware that powder coating is a fantastic painting method that creates a tough, durable and beautiful finish. By using this site, you agree to our, Connect and transact with thousands of top North American companies today, Types Phenolics and Phenolic Materials - A ThomasNet Buying Guide, Types of Crimpers - A ThomasNet Buying Guide, Types of Guardrails - A ThomasNet Buying Guide, Types of Sealing Equipment - A Thomas Buying Guide, Prototypes in Electronics, Computer Software, and Computer Engineering, Types of Electrical Power Supply Interference, Types of Trucks and Carts - A Thomas Buying Guide, Types of Aerospace Adhesives - A ThomasNet Buying Guide, Applications of Precision Stampings (Micro-precision Thin Material, Intricate Precision Metal Work and Prototype Design), Top Aluminum Casting Companies in the USA, Top Aluminum Fabrication Companies and Suppliers in the USA and Canada, Top Metal Manufacturing and Fabricating Companies in the USA, Easter Island's Statues Have Bodies Beneath the Surface, Dealing With Food Waste in the Supply Chain, Maintenance-free, No-adjustment Motor Brakes Help to Alleviate Worker Shortages, Molded Products Manufacturer Announces $5 Million Expansion. They are easy to use in part due to their overbake resistance to yellowing. With liquid paint, horizontal and vertical painted surfaces often have differences in appearances, but powder coating typically provides a uniform visual appearance regardless of orientation. It is these cookies that enable targeted advertising outside of this website. To the most commonly used polyester powder forms are: TGIC and non-TGIC. When the powder is baked, it reacts with other chemical groups in the powder to polymerize, improving the performance properties. The two most common types of Fluoropolymers found in powder coatings are FEVE and PVDF. Unlike epoxy-based resins, acrylics do well in sunlight and blend over a surface, leaving a high gloss, wet-looking finish that is either clear or pigmented. Its almost limitless! Newlow bake powder coatingsallow application on heat sensitive substrates like MDF, engineered wood, plastics or composites.

The polymer granules are mixed with hardener, pigments and other powder ingredients in an, The extruded mixture is rolled flat, cooled and broken into small chips, This page was last edited on 28 July 2022, at 19:31. If you agree with your cookies to be used for all these purposes, click on the I understand button. Polyester TGIC Free powders are exterior durable coatings that offer similar properties to TGIC Polyester but use an alternative curative, also commonly known as Primid cured polyesters. Then you need CRYLCOAT 2441-2, High performance meets extensive resistance, For superdurable coatings even under harsh conditions. These often occur in multiple stages and consist of degreasing, etching, de-smutting, various rinses and the final phosphating or chromating of the substrate and new nanotechnology chemical bonding.

One variation of the dry powder coating process, the Powder Slurry process, combines the advantages of powder coatings and liquid coatings by dispersing very fine powders of 15m sized particles into water, which then allows very smooth, low film thickness coatings to be produced. The powder may be a thermoplastic or a thermoset polymer. According to a market report prepared in August 2016 by Grand View Research, Inc., the powder coating industry includes Teflon, anodizing and electro-plating. This method of preparation is highly efficient on steel parts such as I-beams, angles, pipes, tubes and large fabricated pieces. [11], A major challenge for all low bake systems is to optimize simultaneously reactivity, flow out (aspect of the powder film) and storage stability. Were ready to help you out. Both TGIC and TGIC-free polyesters offer good mechanical resistance, including great flexibility and impact resistance, and good chemical resistance. Silicon carbide grit blast medium is brittle, sharp, and suitable for grinding metals and low-tensile strength, non-metallic materials. [clarification needed]. Nylon also has a very low friction coefficient, making it useful as a coating on gears and conveyor equipment. The polyester does reduce the corrosion and chemical resistance of the epoxies and doesnt really add any outdoor weatherability to the product. Glass bead blast medium contains glass beads of various sizes.

They are a common option utilized in many applications. We also use third-party cookies that help us analyze and understand how you use this website. For applications that involve items permanently outside, super durable polyester may be desirable to increase durability and wearability. Their properties are similar to pure polyesters in terms of impact resistance and durability. Vast majority of powders contain benzoin as degassing agent to avoid pinholes in final powder coating film. Blast media and blasting abrasives are used to provide surface texturing and preparation, etching, finishing, and degreasing for products made of wood, plastic, or glass. FEVE resins are the most popular within the powder community for their superior one coat capability and incredible exterior performance. They also are great electrical insulators for electrical lines, and work well as coatings for chain link fencing.

Some additives are essential to enhance smoothness and flexibility of coatings or to enable formulation of effect coatings leading to wrinkle finishes. One drawback of urethane paint is that at higher mil thicknesses it can begin to outgas and become brittle. [2] This process puts a coating on an item electrostatically, which is then cured by heat. ico-arrow-default-right. As the film thickness is reduced, the film becomes more and more orange peeled in texture due to the particle size and glass transition temperature (Tg) of the powder. The finish is harder and tougher than conventional paint. A coating method for flat materials that applies powder with a roller, enabling relatively high speeds and accurate layer thickness between 5 and 100 micrometres. This has been particularly useful in automotive and other applications requiring high end performance characteristics. Sand blast medium uses high-purity crystals that have low-metal content. Furthermore, coatings based on this polyester powder coating resin show good flexibility, high gloss, and excellent adhesion. The RUCOTE 500 resin series includes polyesters designed to react with epoxy resins in standard powder formulation ratios (50:50, 60:40 and 70:30).

Marketing cookies help us connect this website with social networks such as LinkedIn and Facebook. Adding polyester to an epoxy makes a softer plastic that is less likely to chip or crack. This makes epoxies better suited to indoor applications. Polyester TGIC products are available in General Industrial or Super Durable platforms. On the other hand, they are highly suited for indoor applications. Urethanes are chemically similar to polyesters, with a difference in curing agents. Epoxies and polyesters are often mixed together to form hybrids. If youre coating pieces that will be permanently outside and therefore need good wearability and durability, then consider the super durable polyester instead. Coatings, Adhesives, Sealants, Elastomers, Polyester Resins for Powder Coatings Brochure, New High Functional Low Viscosity Polyester Polyols, New Polymer Technology for Damping Applications at ASC, Excellent physical and aesthetic properties, Low temperature cure or energy saving requirements, Controllable and repeatable gloss levels from dead matte to high gloss, Agricultural and construction equipment (ACE) applications.

Powder coatings are a truly great coating choice with so many product options depending on what you need them to do. Eco-Friendly Metal Finishing: Powder Coating. The global powder coatings market is expected to reach USD 16.55billion by 2024. UV curable powders available now are usable in traditional Corona or Tribo guns, and come in different colors and textures.

There is a wide variety of spray nozzles available for use in electrostatic coating. One of the downsides in powder coating is its inability to coat plastic pieces due to the high heat necessary for the curing process. There are three main categories of powder coatings: thermosets, thermoplastics, and UV curable powder coatings. This website uses cookies to improve your experience. The following information regarding polyester and epoxy powder coatings may help you choose the best option for your application. Super-durable polyester formulations also retain color and gloss in harsh exterior applications. Unlike conventional liquid paint which is delivered via an evaporating solvent, powder coating is typically applied electrostatically and then cured under heat or with ultraviolet light. At the professional scale, the capital expense and time required for a powder coat gun, booth and oven are similar to a spray gun system. Powder coating can also be removed with abrasive blasting. is essential prior to the powder coating process. Powder coating can also be removed by a burning off process, in which parts are put into a large high-temperature oven with temperatures typically reaching an air temperature of 300450C. Powder coating is mainly used for coating of metals, such as household appliances, aluminium extrusions, drum hardware, automobiles, and bicycle frames. Correspondent coatings are recognized for having a high degree of flexibility, adhesion, chemical-, humidity- and corrosion resistance. Most other organic solvents (thinners, etc.) There are many different types of powders used, each with their own characteristics and applications, so making sure you have the right type of powder, and THEN choose the color is very important for a successful application. Many primers are epoxy-based and exhibit excellent corrosion resistance and adhesion strength. This method is generally used when the desired thickness of coating is to exceed 300 micrometres.

While it is relatively easy to apply thick coatings that cure to smooth, texture-free coating, it is not as easy to apply smooth thin films. The global market is predicted to be 20billion dollars by 2027. [14], Increasing demand for tractors in the U.S., Brazil, Japan, India, and China is expected to augment the use of powder coatings on account of its corrosion protection, excellent outdoor durability, and high-temperature performance. These charged powder particles then adhere to the grounded substrate. They are brittle, however, and when exposed to UV light (present in sunlight) they tend to chalk and dull over time. No matter whether youre using a single gun and small oven or a large fully automated line, the process is basically the same.

- 925 Sterling Silver Custom Pendants

- Level Up Mobile Arcade Greensboro Nc

- Opi I Eat Mainely Lobster Vs Cajun Shrimp

- Carved Wood Wall Art With Mirror

- 24 Hour Printing Chicago

- Loewe Cushion Small Tote Bag

- Happy Birthday Cookie Images

- 24 Gauge Stainless Steel Sheet Thickness

polyester powder coat 関連記事

- 30 inch range hood insert ductless

-

how to become a shein ambassador

キャンプでのご飯の炊き方、普通は兵式飯盒や丸型飯盒を使った「飯盒炊爨」ですが、せ …