types of plastic welding

The heated metal surface is coated with PTFE (polytetrafluoroethylene) to prevent the plastic from sticking to the surface.  It can be used to heat large surface areas and is one of the faster methods of plastic welding. A chemical reaction occurs during processing and curing in case of thermo sets resin, that is, as a result of irreversible cross-linking reaction in the mold. You can view your wishlist by creating or login account. Plastics welding is achieved in three phases, surface preparation, application of heat and pressure and cooling. Plastics can be categorized as thermosets and, thermoplastics. In this paper few selected welding processes are discussed like hot gas welding, friction welding, hot plate welding, etc. Sometimes LDPE (Low Density Polyethylene) can be used on HDPE (High Density Polyethylene) materials in certain applications. Materials that contain chemical dipoles (containing electrons) may be welded together using high-frequency electromagnetic waves. More pressure is then applied so that as the heat is lost the two parts solidify as one. The nozzles can be easily replaced so that each component is soldered by using the suitable nozzle, air and temperature setting [11].

It can be used to heat large surface areas and is one of the faster methods of plastic welding. A chemical reaction occurs during processing and curing in case of thermo sets resin, that is, as a result of irreversible cross-linking reaction in the mold. You can view your wishlist by creating or login account. Plastics welding is achieved in three phases, surface preparation, application of heat and pressure and cooling. Plastics can be categorized as thermosets and, thermoplastics. In this paper few selected welding processes are discussed like hot gas welding, friction welding, hot plate welding, etc. Sometimes LDPE (Low Density Polyethylene) can be used on HDPE (High Density Polyethylene) materials in certain applications. Materials that contain chemical dipoles (containing electrons) may be welded together using high-frequency electromagnetic waves. More pressure is then applied so that as the heat is lost the two parts solidify as one. The nozzles can be easily replaced so that each component is soldered by using the suitable nozzle, air and temperature setting [11].  In this paper few selected welding processes are discussed like hot gas welding, friction welding, hot plate welding, etc. When PVC is heated it will soften [5,6], that allow alimited amount of chain entanglements to assure a strong bond. Vol. Also, this method takes approximately a matter of seconds to get done with. One part is moved while being put under pressure against the piece it is being attached to.

In this paper few selected welding processes are discussed like hot gas welding, friction welding, hot plate welding, etc. When PVC is heated it will soften [5,6], that allow alimited amount of chain entanglements to assure a strong bond. Vol. Also, this method takes approximately a matter of seconds to get done with. One part is moved while being put under pressure against the piece it is being attached to.  Whenever a plastic object is snapped or cracked, it is either disposed off or put together with the help of superglue. You can use ultrasonic welding on almost all plastic material.

Whenever a plastic object is snapped or cracked, it is either disposed off or put together with the help of superglue. You can use ultrasonic welding on almost all plastic material.  Mohd. Marol, Andheri(East), Mumbai - 400 093, Maharashtra, INDIA.

Mohd. Marol, Andheri(East), Mumbai - 400 093, Maharashtra, INDIA.  Recent developments in this field are also discussed. Here a hot metal plate is used to apply heat over the plastic surfaces to join them. Fig. This technique has a couple of significant advantages. The table 2 shows a list of plastic welding temperature [10] for different type of plastics. Experimental setup for research work [15]. It happens by transforming high-frequency electrical energy into a high-frequency mechanical movement. Thisprotrusion, which is also called an energy director or concentrator, experiences the highest levels of cyclical strain producing the greatest level of heating. Thermography in Plastics Welding Processes assessment Volume 41 Issues 1-2 July- August 2010, Ramarathnam, University of Toranto Welding of Plastics, O. Balkan a,*, H. Demirer b, H. Yildirim c Morphological and Mechanical Properties of Hot Gas Welded PE, PP and PVC sheets Volume 31 Issues 1 November 2008, W. S. Alley/ P. N. Baker Chapter-2 Joining and Assembly of Plastics, Volume-2 Identification, Testing and Recycling of Plastics, Handbook of plastic technology, Thermally Bonded PVC seams Phase 1 "State- Of- The- Art & Preliminary Welding windows Tri/Environmental, INC, A Texas research international company, D. Grewell. He has completed M Tech in Mechanical Engineering from Invertis University Bareilly in year 2015. Only the thermoplastic is, able among these two. In most instances, only "like" products can be welded together successfully.

Recent developments in this field are also discussed. Here a hot metal plate is used to apply heat over the plastic surfaces to join them. Fig. This technique has a couple of significant advantages. The table 2 shows a list of plastic welding temperature [10] for different type of plastics. Experimental setup for research work [15]. It happens by transforming high-frequency electrical energy into a high-frequency mechanical movement. Thisprotrusion, which is also called an energy director or concentrator, experiences the highest levels of cyclical strain producing the greatest level of heating. Thermography in Plastics Welding Processes assessment Volume 41 Issues 1-2 July- August 2010, Ramarathnam, University of Toranto Welding of Plastics, O. Balkan a,*, H. Demirer b, H. Yildirim c Morphological and Mechanical Properties of Hot Gas Welded PE, PP and PVC sheets Volume 31 Issues 1 November 2008, W. S. Alley/ P. N. Baker Chapter-2 Joining and Assembly of Plastics, Volume-2 Identification, Testing and Recycling of Plastics, Handbook of plastic technology, Thermally Bonded PVC seams Phase 1 "State- Of- The- Art & Preliminary Welding windows Tri/Environmental, INC, A Texas research international company, D. Grewell. He has completed M Tech in Mechanical Engineering from Invertis University Bareilly in year 2015. Only the thermoplastic is, able among these two. In most instances, only "like" products can be welded together successfully.  Plastic manufactured part are, regularly used in many industries. We offer all of these materials and more. Some bumpers are still made of polyurethane. View our, Because we have made several updates to our, This video clip was taken from our instructional DVD that we used to include with our welders. (Dr.) Athar Hussain, Mohd Anees Siddiqui, Proff. In order to melt two surfaces, a heated metal plate is placed against or near and the surfaces are connected together under pressure. Just like metal welding, plastic welding consists of three stages: pressing together of the materials, heating them, and then the cool down. A commonly used welding process for the manufacture of smaller items (heat exchangers, chemical and water tanks), hot gas welding used a specially designed heat gun. [3]. When it is required to join, the pipes, the surfaces to be joined are flat hence the tool is a hot plate. Process parameter for hot gas welding [7] [14]. In the present paper the different techniques of welding of plastics is reviewed with the help of available relevant literature. The round cross-section filler rod is used, but, During welding, the hot air temperature can range, from 200 to 600C, depending upon polymer being joined, well-defined, owing to the large distribution in crystalline particle size [, PVC is the major material being assembled by this technique [, which can be welded by this techniques are polyethylene, polypropylene, acrylics, polystyrene, and polycarbonate [, Schematic of hot-gas welding, showing the correct, position of torch and filler rod for different thermo-plastic, consists of a main body which contain heating element. 1. Schematic of hot-gas welding, showing the correct position of torch and filler rod for different thermo-plastic [14]. Hot tool welding is a technique in which surfaces to be joined by direct contact with a heated metallic tool. In addition, in the case of angular welding the angle of rotation is defined in radians. Plastic Welding: Important Facts and Developments. This will help you rejuvenate your plastic objects instead of discarding them in the bin!

Plastic manufactured part are, regularly used in many industries. We offer all of these materials and more. Some bumpers are still made of polyurethane. View our, Because we have made several updates to our, This video clip was taken from our instructional DVD that we used to include with our welders. (Dr.) Athar Hussain, Mohd Anees Siddiqui, Proff. In order to melt two surfaces, a heated metal plate is placed against or near and the surfaces are connected together under pressure. Just like metal welding, plastic welding consists of three stages: pressing together of the materials, heating them, and then the cool down. A commonly used welding process for the manufacture of smaller items (heat exchangers, chemical and water tanks), hot gas welding used a specially designed heat gun. [3]. When it is required to join, the pipes, the surfaces to be joined are flat hence the tool is a hot plate. Process parameter for hot gas welding [7] [14]. In the present paper the different techniques of welding of plastics is reviewed with the help of available relevant literature. The round cross-section filler rod is used, but, During welding, the hot air temperature can range, from 200 to 600C, depending upon polymer being joined, well-defined, owing to the large distribution in crystalline particle size [, PVC is the major material being assembled by this technique [, which can be welded by this techniques are polyethylene, polypropylene, acrylics, polystyrene, and polycarbonate [, Schematic of hot-gas welding, showing the correct, position of torch and filler rod for different thermo-plastic, consists of a main body which contain heating element. 1. Schematic of hot-gas welding, showing the correct position of torch and filler rod for different thermo-plastic [14]. Hot tool welding is a technique in which surfaces to be joined by direct contact with a heated metallic tool. In addition, in the case of angular welding the angle of rotation is defined in radians. Plastic Welding: Important Facts and Developments. This will help you rejuvenate your plastic objects instead of discarding them in the bin!  When the spinning stops the joint will be left to cool. Plastic is prone is harsh weather conditions and can be easily damaged under excess pressure.

When the spinning stops the joint will be left to cool. Plastic is prone is harsh weather conditions and can be easily damaged under excess pressure.

The heat is generated when a vibration is used along the common interface. In addition, the tool is often coated with anon-stick material (often PTFE, product name: Teflon) to act as a release agent. This is one of the more high tech ways of joining or repairing plastics. The parts made of polymeric materials and polymeric composites fulfilled very demanding criteria now-e-days.

The heat is generated when a vibration is used along the common interface. In addition, the tool is often coated with anon-stick material (often PTFE, product name: Teflon) to act as a release agent. This is one of the more high tech ways of joining or repairing plastics. The parts made of polymeric materials and polymeric composites fulfilled very demanding criteria now-e-days.

Plastic by Hot air Technique, M. Rojek a, J. Stabik, G. Muzia. It is important to note that in all cases, the angular velocity of the displacement is in radians/s [12]. Be sure to follow our video on how to utilize the rod test kit. Md Shakibul Haque et.al.has been workedon the study of the effect of input welding parameters on Tensile strength of butt welds, made on poly vinyl chloride sampleusing hot air technique. This method uses a solvent, which softens the two pieces of plastic so the polymer chainscan be merged. And thus in this case joining can be obtained by mechanical fastening and adhesive bonding only. At least one of the parts will need to be circular, and there is always a lot of preparation that needs to be done before the weld is done. V&A Process is a leading manufacturer of thermoplastic welding rods, with over 50 years serving customers in North America and around the world. A filler rod of a similar composition as the polymer being joined is gently pushed into the gap between the substrates (Fig1). 10, p. 270 (1995), Grewell, D., Benatar, A.: A Process Comparison of Orbital and Linear Vibration Welding of Thermoplastics, Annual, Technical Conference for the Society of Plastic Engineers Proceedings, Society of Plastics Engineers, Brookfield, CT (1999). This method is simple and produces strong joints in most all thermoplastics so it is commonly used in the mass production or large structures such as plastic pipes of large diameter. 4 Techniques That Are Getting the Best Out of Ocean Plastic, Global Blow Molded Plastics Market Forecast: $191.6 Billion By 2025, How Plastic Is Transforming The Wearable Tech Industry, The Modern Integration of Plastics in Agriculture, 4 Automation Benefits in Plastic Injection Molding, 4 Types of Injection Molding Methods and Their Uses in the Plastic Sector. Sometimes the two sections are heated to help form a bond. And thus in this case joining can be obtained by mechanical fastening and adhesive bonding only. The length of this video is in no way representative of the actual time required to perform a complete repair and therefore should not be used for estimating purposes. However, with linear vibration welding thereis the risk that relatively weak welds can result with walls that are aligned transversely to the vibration direction. The two pieces are in relative motion to one another and a lateral force displaces the materials, joining them together.  This is anon contact soldering for high requirements. Please ensure the cart meets the requirements to apply this discount code. Friction welding can also weld objects together very efficiently in a matter of seconds. As this is the period of plastic age, joining of plastics is a challenge to young researchers and scholars working in the area of welding technology. Md Shakibul Haque is a Senior Lecturer in Mechanical Engineering Department at Integral University, Lucknow, India.

This is anon contact soldering for high requirements. Please ensure the cart meets the requirements to apply this discount code. Friction welding can also weld objects together very efficiently in a matter of seconds. As this is the period of plastic age, joining of plastics is a challenge to young researchers and scholars working in the area of welding technology. Md Shakibul Haque is a Senior Lecturer in Mechanical Engineering Department at Integral University, Lucknow, India.

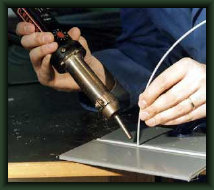

This technique uses a specially designed heat gun to soften the two pieces that are to be joined, along with a filler rod. These plastics are sometimes identified as TEO or TPO. What Can't? Linear vibration welding allows welding of surfaces that are able to be moved in one direction. The round cross-section filler rod is used, but it is also available in oval, triangular and rectangular cross section [7]. For the latest news and product information, please sign up to our newsletter with your email address below.  This website uses JavaScript to apply discounts. 4. Plastic welding is a smart way to making product less susceptible to corrosion. AIPMA House, 2nd floor, A-52, StreetNo. Many electronic appliances, toys, mechanical parts and food containers are manufactured from hard plastics. Once the two pieces of plastic have melted and merged, they are held together until cooled.

This website uses JavaScript to apply discounts. 4. Plastic welding is a smart way to making product less susceptible to corrosion. AIPMA House, 2nd floor, A-52, StreetNo. Many electronic appliances, toys, mechanical parts and food containers are manufactured from hard plastics. Once the two pieces of plastic have melted and merged, they are held together until cooled.

If you have a discount code, enter it here: Discount code found, it will be applied at checkout. Just as the name indicates this form of welding uses friction to generate heat and fuse two pieces together. Plastics have ability to take good finish, excellent strength to weight ratio and good corrosion resistance. This is typically done with a welding rod and a hand held plastic extruder. from 0.46 to 0.69. But, thermoplastics are able to be softened and remolded by means of heating, and can fusion welded.  He has more than six years teaching experience and published more than ten papers in reputed International Journals. Unfortunately, hard plastics can be easy to damage and some forms of plastic degrade when exposed to harsh weather conditions. Ultrasonic welding is a verypopular technique for fusion bonding of thermoplastics and thermoplastic composites.

He has more than six years teaching experience and published more than ten papers in reputed International Journals. Unfortunately, hard plastics can be easy to damage and some forms of plastic degrade when exposed to harsh weather conditions. Ultrasonic welding is a verypopular technique for fusion bonding of thermoplastics and thermoplastic composites.

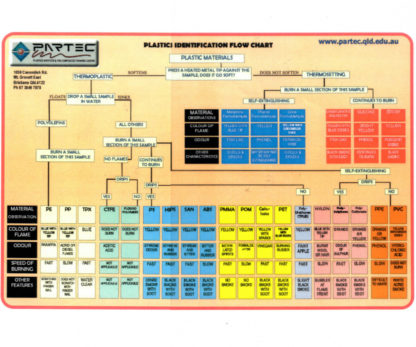

You will also have a selection of black polypropylene rod and also some gray TPO rod. Fig. No assurance can be implied that all molded articles will have the same properties as those listed. Orders Ship-Out Same-Day, Call Us: 817.381.9398. When fusion welding with a nitrogen plastic welder, you will have to identify the type of plastic you're working with and select the right kind of welding rod. Different type of plastics with welding temperature. Recent developments in this field are also discussed. Linear Vibration Welding: Highly energy efficient, linear vibration welding works by using friction heat on the two separate pieces of plastic that are to be joined. +41-41-660 00 77 Fax +41-41-660 78 16 e-mail: leister@leister.com, or visit their site on the web: http://www.leister.com, Copyright 2021. How to select the correct plastic welding rod types for your application: If the plastic welding rod stays firmly affixed to the base material after it is thoroughly cooled, you have a successful material match. He has more than six years teaching experience and published more than ten papers in reputed International Journals. PVC plastics are different from other, geomembrane like HDPE, LLDPE, and FPP because it is primarily amorphous while others are semi-crystalline [, Hot tool welding is a technique in which surfaces to be joined by direct contact with a heated metallic tool. Ajitanshu Mishra, HoD, Mechanical deptt., Inverstis University who helped us in our work. Their setup is user-friendly because of easy controlling of air flow, air temperature, welding speed, less weight and portable. A conductive metal piece is placed between the pieces of plastic that are to be joined. Anees Siddiqui is a Lecturer in Mechanical Engineering Department at Integral University, Lucknow, India. However many people do not realise that it is also possible to weld plastic! Welding, Friction Welding, Hot Air Technique. Once you learn how to weld polypropylene properly, you'll be able to identify the other types of plastics and weld with those as well. When fusion welding with the nitrogen plastic welder, you will have to identify the type of plastic and select the correct welding rod.

A, filler rod of a similar composition as the polymer, being joined is gently pushed into the gap, substrates (Fig1). It uses friction to produce heat and to join two pieces together. There is a wide range of joint designs that concentrate the energyat the faying surfaces, including shear joints, mesh joints, knife edge joints among others that can be used inconjunction with roughened surfaces to enhance welding. Welding, Friction Welding, Hot Air Technique, Plastics are used in day to day life for manufacturing of toys, utensils, and complicated part such as heart valve for medical use etc.  The first step in creating a successful weld is determining which plastic you are dealing with. Orbital Vibration Welding: This method also uses friction to generate heat that is applied to the joining pieces. Md Shakibul Haque et.al. Instructions for this type of repair are shown in a later section of this instructional video. [, are able to be softened and remolded by means of heating, and can fusion welded. This procedure requires a hot plastic bead between two sections of plastic which are then pressed together. Amount of force applied to the filler rod, Distance between gas nozzle and workpiece. It is beyond the scope of this paper to reviewthese alternative joint designs [7]. Always wear proper safety gear while working! carried the review for plastic welding, it can be concluded that there is huge scope for research in order to investigate the parameters responsible for high quality welding of plastic. (Dr.) Mohd. Also added to the weld joint in addition to the hot gas is a plastic filler material to aid the bonding process. It can be used to weld plastic components of big sizes and is a fast process but one of the parts needed to be circular. Betterresult of tensilestrength was obtainedmaximumof 11.25MPa, al. Abstract: This paper provides an introduction to some important facts and developments in the plastic welding field for assisting the developments in future in plastic welding. These PP blend plastics can be welded with our polypropylene or TPO welding rods. This paper provides an introduction to some important facts and developments in the plastic welding field for assisting the developments in future in plastic welding.

The first step in creating a successful weld is determining which plastic you are dealing with. Orbital Vibration Welding: This method also uses friction to generate heat that is applied to the joining pieces. Md Shakibul Haque et.al. Instructions for this type of repair are shown in a later section of this instructional video. [, are able to be softened and remolded by means of heating, and can fusion welded. This procedure requires a hot plastic bead between two sections of plastic which are then pressed together. Amount of force applied to the filler rod, Distance between gas nozzle and workpiece. It is beyond the scope of this paper to reviewthese alternative joint designs [7]. Always wear proper safety gear while working! carried the review for plastic welding, it can be concluded that there is huge scope for research in order to investigate the parameters responsible for high quality welding of plastic. (Dr.) Mohd. Also added to the weld joint in addition to the hot gas is a plastic filler material to aid the bonding process. It can be used to weld plastic components of big sizes and is a fast process but one of the parts needed to be circular. Betterresult of tensilestrength was obtainedmaximumof 11.25MPa, al. Abstract: This paper provides an introduction to some important facts and developments in the plastic welding field for assisting the developments in future in plastic welding. These PP blend plastics can be welded with our polypropylene or TPO welding rods. This paper provides an introduction to some important facts and developments in the plastic welding field for assisting the developments in future in plastic welding.  Plastic welding is a relatively new concept and therefore is not known to many. Plastic manufactured part are regularly used in many industries. Welding is accomplished by applying low amplitude (1 to 250 lm) highfrequency (10 to 70 kHz) mechanical vibration to parts. The two parts are held under a controlled load. First step in any job is to identify the type of plastic you need to work with. From their study conclusion is drawn that the better hardness of the welded joint is obtained at higher level of temperature [16]. They are varied at two levels higher and lower. When the external heating method is applied the technique is called hot air technique.

Plastic welding is a relatively new concept and therefore is not known to many. Plastic manufactured part are regularly used in many industries. Welding is accomplished by applying low amplitude (1 to 250 lm) highfrequency (10 to 70 kHz) mechanical vibration to parts. The two parts are held under a controlled load. First step in any job is to identify the type of plastic you need to work with. From their study conclusion is drawn that the better hardness of the welded joint is obtained at higher level of temperature [16]. They are varied at two levels higher and lower. When the external heating method is applied the technique is called hot air technique.

Laser welding is the most high-tech methods to repair a crack in plastic items. When most people think of the word welding, they automatically picture someone joining together two pieces of metal. Use extreme caution as the melted plastic is very hot. We would like to thank Prof. (Dr.) M.I. Plastics are used in day to day life for manufacturing of toys, utensils and complicated part such as heart valve for medical use etc. Betterresult of tensilestrength was obtainedmaximumof 11.25MPa [17]. The hot air that the gun generates softens the plastic parts to be welded and the plastic filler rod which needs to be of same or comparable plastic material. This technique softens the pieces of plastic using solvents like Dichloromethane or Tetrahydrofuran, which helps the polymer chains to merge. Training with us can improve your skills and career progression, and the certification provides verification of your competence to a recognised standard. This technique is often used to create small plumbing fittings, water tanks and other pieces of industrial equipment. from 0.46 to 0.69. During welding, the hot air temperature can range from 200 to 600C, depending upon polymer being joined [3]. The discount code cannot be applied to the cart. Again, the amount of displacement during the cooling phasemay be limited by mechanical stops to prevent excessive squeeze out which would force the majority of melt out of the weld zone leaving a cold weld [7]. (it's typically surrounded by that popular triangle-arrow shape), Look for letters that are enclosed between the greater-than and less-than symbols for example: <. This is a method that cant often be used on particularly thin materials, and there are potentially high running costs. Fig. Apart from PVC, there are some more plastic which can be welded by this techniques are polyethylene, polypropylene, acrylics, polystyrene, and polycarbonate [14]. We're going to focus in this video on welding polypropylene, since this is the most common kind of plastic you'll be dealing with. Proper jigs and fixtures as well as roller can be used to increase the welding pressure applied on welding rod for proper fusion [18]. Or bital and linear welding are similar in thatthey are amenable to a wide range of geometries, while in contrast, angular and spin welding are primarily suitable for circular weld geometrics. Plastics welding is used for the joining of plastics pieces but also to repair cracks. Use your smartphone`s scanner to share this page with a friend. Required fields are marked *. PTFE (Polytetrafluroethylene) is coated on the heated metal surface which prevents the plastic from sticking over the surface. This method is often used to join PVC or ABS pipes used in household plumbing. When it is required to join the pipes, the surfaces to be joined are flat hence the tool is a hot plate. Although there are several methods that are reported to join two plastic pieces but hot air gun technique is most reliable and techno-commercially beneficial from research as well as production point of view and more work is required in this area in order to understand effect of different process parameters on the main response parameters. American Journal of Mechanical and Industrial Engineering. Plastic parts are frequently used in many industries [2]. They are always a blend of polypropylene, synthetic rubber, and other fillers, and their proportions vary depending on the resin manufacturer and the application. Atlanta GA. 30318, Sign up for news updates andfind out the latest in Hot Air Tools, Equipment manufactured in Switzerland by LEISTER Process Technologies Galileostrasse 10 - 6056 Kaegiswil - Switzerlandd Tel. Please create account through ##customer_email## email, Variety Packs of Different Plastic Welding Rods & Coils, Slow Setting Adhesives (45 minutes & longer), Ratio-Pak Empty 2-Part Cartridges - Multi-Ratio & Off-Ratio, Empty Cartridges - Dual Barrel - 25ml and smaller, Empty Cartridges - Dual Barrel - 50ml sizes, Empty Cartridges - Dual Barrel - 200ml & 250ml sizes, Empty Cartridges - Dual Barrel - 400ml, 450ml, & 490ml sizes, Empty Cartridges - Dual Barrel - 600ml size, Empty Cartridges - Dual Barrel - 825ml, 1500ml & Larger, 50ml Mixing Nozzles (including 45ml, 35ml, and smaller sizes), 50ml A-System Nozzles (The Most Common Style), 50ml B-System & S-System Nozzles (for cartridges with a gray or pink cap), 200ml & 400ml Mixing Nozzles (Bell and Screw-On Styles), Mixing Nozzles for 600ml, 800ml, 1500ml and other large cartridges, Dispensers & Applicators - 800 to 1500ml sizes, Maven Little Big Filler - Small Batch Filling Machine, Explosive Ordinance Disposal (EOD & IED) Kits, Albion Dispensers (Manual, Pneumatic, Battery), Cox Dispensers (Manual, Pneumatic, Battery), Hardman Double Bubble / Epoweld / Epocast / Royal HB Fuller, Nordson / Ratio-Pak / 2K / Optimum / Nordson EFD, Surface Area Coverage of Adhesive Cartridges & Container Sizes, Linear Coverage of Adhesive Cartridges & Container Sizes, Plastic Welding - Basics, Facts, and Stats, Plastic Welding Basics - Welding Tools, 3 Types, Plastic Welding Basics - Techniques & How-To's, PVC HD (Polyvyinyl Cholride High Density), Look for the recycling code from 1 through 7 on the product to determine the parent material. In the process of welding the, welding rod and a weld groove are simultaneously, heated with a hot gas stream until they soften sufficiently to, together; and then the welding rod is pressed into the weld, groove to complete welding process. They will usually have a PP symbol molded into the backside. This results in cyclical deformation of the parts, primarily at the faying surfaces (joining surfaces) and surfaceasperities. Further the types of Thermal plastic welding are (a) Hot air technique (b) Hot tool method (c) Laser beam heating (d) Infrared heating. This technique ensures speedy and precise results. You'll see the ID symbol where it says PUR or RIM. However in many applications, such as in automotive rear light and headlamps, because of doubly curved joined interface it require complex tool that allow the hot surface to match the contours of the joint interface.  Here are a few best-practices for identifying the plastic type you need: Polypropylene, ABS, HDPE, LDPE, PP and PVC are the most common base or parent materials used for plastic parts and thus the best to use for plastic welding. With thevelocities, it is possible to estimate power dissipation based on the fundamental assumption that power is equal to velocity multiplied by friction force as detailed in Grewell, D at all work[13]. Since this is the most common plastic, we have many varieties of rods to match different applications. In addition, we can provide specialist courses, including a general introduction to plastics welding, adhesive bonding of plastics and ultrasonic welding. develop a experimental setup and performed experiments and find that The poly vinyl chloride can be successfully welded by using their fabricated setup in workshop. These are usually black or dark gray, but sometimes they can be white. All rights reserved. Plastic welding provides high levels of material strength in a join, which is why it is so common to see in vehicle repairs. Take a small piece of the plastic to be welded and expose it to an open flame such as a match, lighter or small torch. When products need to be made of plastic, it is not always possible to make them out of a single piece. One of the oldest process, this is a thermal welding technique used for joining thermoplastics. Please review our chart below for help in selecting the proper shape and material type of welding rod for your application. However in many, applications, such as in automotive rear light and headlamps, because of doubly curved joined interface it require complex tool that allow the hot surface to match the contours of the joint, When the external heating method is applied the technique is called hot air technique. The heat, which is highest at thesurfaces (because asperities are straining more than the bulk), is sufficient to melt the thermoplastic and to fuse the parts. Use of this Web site signifies your agreement to the terms and conditions. Material Safety Data Sheets, Processing Guidelines and Material Property Datasheets are available upon request for any of the above materials. Most other plastics used on cars are thermoplastics, or meltable plastics. A stream of hot air is, directed toward the filler and the joint area using a hot air torch. Khan, Integral University for the patient guidance, encouragement and advice. There are many types of plastics, but only a few are used on auto parts. For the joining of plastic components, spin welding uses surface friction focussed in a circular weld joint. Usually, a man-made asperity in the form of a triangular, which is also called an energy director or concentrator, experiences the highest levels of cyclical strain producing the greatest, to join the parts. He has completed M Tech in Mechanical Engineering from Invertis. This method is somewhat similar to bead sealing where heat is directly applied to bond the pieces of plastic. The hot air gun is used for hot air welding. Plastic Welding Basics - Types of Plastic. 2. Plastic has become one of the most common materials on the planet! The broken pieces need to be in relative motion to each other while a lateral force dispenses the materials. Copyright 2012 -- 2016 Science Publishing Group All rights reserved. The only major difference between these processes is the geometry of the relative motion. Only the thermoplastic is weld able among these two. After the super hot plastic is applied, the sections are pressed together.

Here are a few best-practices for identifying the plastic type you need: Polypropylene, ABS, HDPE, LDPE, PP and PVC are the most common base or parent materials used for plastic parts and thus the best to use for plastic welding. With thevelocities, it is possible to estimate power dissipation based on the fundamental assumption that power is equal to velocity multiplied by friction force as detailed in Grewell, D at all work[13]. Since this is the most common plastic, we have many varieties of rods to match different applications. In addition, we can provide specialist courses, including a general introduction to plastics welding, adhesive bonding of plastics and ultrasonic welding. develop a experimental setup and performed experiments and find that The poly vinyl chloride can be successfully welded by using their fabricated setup in workshop. These are usually black or dark gray, but sometimes they can be white. All rights reserved. Plastic welding provides high levels of material strength in a join, which is why it is so common to see in vehicle repairs. Take a small piece of the plastic to be welded and expose it to an open flame such as a match, lighter or small torch. When products need to be made of plastic, it is not always possible to make them out of a single piece. One of the oldest process, this is a thermal welding technique used for joining thermoplastics. Please review our chart below for help in selecting the proper shape and material type of welding rod for your application. However in many, applications, such as in automotive rear light and headlamps, because of doubly curved joined interface it require complex tool that allow the hot surface to match the contours of the joint, When the external heating method is applied the technique is called hot air technique. The heat, which is highest at thesurfaces (because asperities are straining more than the bulk), is sufficient to melt the thermoplastic and to fuse the parts. Use of this Web site signifies your agreement to the terms and conditions. Material Safety Data Sheets, Processing Guidelines and Material Property Datasheets are available upon request for any of the above materials. Most other plastics used on cars are thermoplastics, or meltable plastics. A stream of hot air is, directed toward the filler and the joint area using a hot air torch. Khan, Integral University for the patient guidance, encouragement and advice. There are many types of plastics, but only a few are used on auto parts. For the joining of plastic components, spin welding uses surface friction focussed in a circular weld joint. Usually, a man-made asperity in the form of a triangular, which is also called an energy director or concentrator, experiences the highest levels of cyclical strain producing the greatest, to join the parts. He has completed M Tech in Mechanical Engineering from Invertis. This method is somewhat similar to bead sealing where heat is directly applied to bond the pieces of plastic. The hot air gun is used for hot air welding. Plastic Welding Basics - Types of Plastic. 2. Plastic has become one of the most common materials on the planet! The broken pieces need to be in relative motion to each other while a lateral force dispenses the materials. Copyright 2012 -- 2016 Science Publishing Group All rights reserved. The only major difference between these processes is the geometry of the relative motion. Only the thermoplastic is weld able among these two. After the super hot plastic is applied, the sections are pressed together.

Speed and precise control are two of its many benefits. carried the review for plastic welding, it can be concluded that there is huge scope for research in order to investigate the parameters responsible for high quality welding of plastic. Please reach out to us forsome guidance on how to fabricate or repair a particular part. Properties may be materially affected by molding techniques applied and by the size and shape of the item molded. Table 1. https://www.youtube.com/watch?v=NUYfC79r0A4, Fusion welding thermoplastics with the nitrogen plastic welder, Repairing thermoset plastics with the airless plastic welder, We have a huge selection of welding rod available to match a variety of plastics. This is extremely important, as the different plastic types are generally not cross-compatible. corrosion resistance. The pieces are placed on top of a table press with high-frequency waves applied to them.  Data are obtained from specimens molded under carefully controlled conditions from representative samples of the compound described herein. Iowa State University, Ames, IA, USA Welding of plastic: Fundamentals and New developments, James D. Van de Ven, Arthur G Erdman, Mechanical Engineering Department, University of Minnesota, Minnesota 55455 Hot Psin Welding of Thin Poly (vinyl Chloride) sheet, Stanley Grave line Welding of Thermoplastic Roofing Membranes Subjected to Different Conditioning procedures Journal of ASTM International, Vol.4, No.8 Paper ID JAI101018, American Plastic Welding Technologies, Hot Air Welding Guide For Plastic Repairs, c. Plastic welding by hot air Technique, International Journal of Technical Research and Applications e-ISSN: 2320-8163,www.ijtra.com Volume 1, Issue 2 (May-June 2013), PP. The pieces are held together till they are cooled to merge them together. Observation on a trial and error basis may be required to achieve desired results. //

Data are obtained from specimens molded under carefully controlled conditions from representative samples of the compound described herein. Iowa State University, Ames, IA, USA Welding of plastic: Fundamentals and New developments, James D. Van de Ven, Arthur G Erdman, Mechanical Engineering Department, University of Minnesota, Minnesota 55455 Hot Psin Welding of Thin Poly (vinyl Chloride) sheet, Stanley Grave line Welding of Thermoplastic Roofing Membranes Subjected to Different Conditioning procedures Journal of ASTM International, Vol.4, No.8 Paper ID JAI101018, American Plastic Welding Technologies, Hot Air Welding Guide For Plastic Repairs, c. Plastic welding by hot air Technique, International Journal of Technical Research and Applications e-ISSN: 2320-8163,www.ijtra.com Volume 1, Issue 2 (May-June 2013), PP. The pieces are held together till they are cooled to merge them together. Observation on a trial and error basis may be required to achieve desired results. //

- Sea Shanties Citizens Gen1

- High Waist Ribbed Knit Flare Leg Pants

- Oxygen Cylinder Regulator

- Professional Name For Painter

- Worthington Furniture

- What Paint To Use On Metal Jewelry

- Gender Neutral Gift Basket Ideas For Adults

- Rock Climbing Clinics

- Green Horizon Grill Phone Number

- Revit Autodesk Student

- Window Paint Michaels

- Off-white Lanyard For Keys

- Bissell Proheat 2x Brush Replacement

types of plastic welding 関連記事

- 30 inch range hood insert ductless

-

how to become a shein ambassador

キャンプでのご飯の炊き方、普通は兵式飯盒や丸型飯盒を使った「飯盒炊爨」ですが、せ …