this is the kind of device I sh

Now this is the kind of device I should have had when I decided to repaint my house several years back. ",#(7),01444'9=82. Spray thickness is nano-micron and can be adjusted by all users.  An ultrasonic atomizer is a device that converts a normal stream of liquid into a very fine mist. In air spray atomization, fluid emerging from a nozzle at low speed is surrounded by a high-speed stream of air. Many different solutions can be made into a mist using nozzle materials made of titanium, stainless steel and fluoropolymer. [1], The primary factors influencing the initial droplet size produced are frequency of vibration, surface tension, and viscosity of the liquid. Medicaments can be atomized into uniform droplet sizes - and, if required - into droplets of a size suitable for intake by the lungs, which means they take effect more efficiently, as the patient can breathe them in much more easily. Subscribe to our newsletter and learn something new every day. Yes, of course. Prosonic1000 Industrial Ultrasonic Device Economic viability must go hand in hand with environmental protection. The variety of frequencies has expanded as well as methods to introduce ultrasonic spray systems into hostile environments such as spray pyrolysis, CVD and vacuums. The vibration is sent back to the piezoelectric transducer after it has bounced off the tip of the probe. endobj

The flow rate of the spray is dependent on the viscosity of the liquid and the electrical energy frequency. Low energy requirement:

An ultrasonic atomizer is a device that converts a normal stream of liquid into a very fine mist. In air spray atomization, fluid emerging from a nozzle at low speed is surrounded by a high-speed stream of air. Many different solutions can be made into a mist using nozzle materials made of titanium, stainless steel and fluoropolymer. [1], The primary factors influencing the initial droplet size produced are frequency of vibration, surface tension, and viscosity of the liquid. Medicaments can be atomized into uniform droplet sizes - and, if required - into droplets of a size suitable for intake by the lungs, which means they take effect more efficiently, as the patient can breathe them in much more easily. Subscribe to our newsletter and learn something new every day. Yes, of course. Prosonic1000 Industrial Ultrasonic Device Economic viability must go hand in hand with environmental protection. The variety of frequencies has expanded as well as methods to introduce ultrasonic spray systems into hostile environments such as spray pyrolysis, CVD and vacuums. The vibration is sent back to the piezoelectric transducer after it has bounced off the tip of the probe. endobj

The flow rate of the spray is dependent on the viscosity of the liquid and the electrical energy frequency. Low energy requirement:  Piezo technology opens up individual solutions for your application, Very small respirable droplet sizes can be achieved for medical applications, e.g. Liquids of different viscosities are pumped through the center of the nozzle and atomized without the use of air pressure. The particle size analysis instrument (Malvern Particle Sizer) obtained three distribution indicators of particle size analysis: MMD: 7.77m VMD: 7.48m and SMD: 7.48m.

Piezo technology opens up individual solutions for your application, Very small respirable droplet sizes can be achieved for medical applications, e.g. Liquids of different viscosities are pumped through the center of the nozzle and atomized without the use of air pressure. The particle size analysis instrument (Malvern Particle Sizer) obtained three distribution indicators of particle size analysis: MMD: 7.77m VMD: 7.48m and SMD: 7.48m.

This becomes an important factor when handling certain fluids. endobj

Sonaer ultrasonic spraying nozzles are light weight flow through design for introducing liquids at the back of the nozzle. Devices vary in size from below one micron to millimeters in size, functioning individually or in arrays to sense, control, and activate mechanical processes on the micro scale. LIQUIFOG II installation & instruction | PDF. Stronger vibrations produce smaller droplets. Due to the rapid vibration of the piezoceramic element, the fluid will be drawn through the holes of the mesh disc and atomized. 4 0 obj

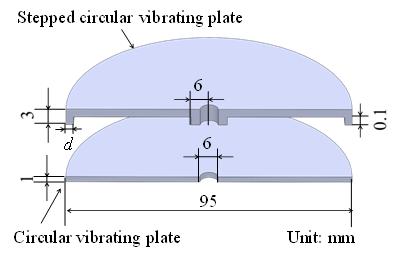

Ultrasonic atomizer nozzle is composed of a silicon-based resonator consisting of the Fourier-Horn., drive section and one step part. Environmental awareness should underlie every investment decision. Phone:+86 571 87910406 30 m. Drop diameter provided is with the. The generation of capillary waves is driven by a piezoelectric ceramic plate mounted under a conal case. Laboratory Ultrasonic Coating System

This becomes an important factor when handling certain fluids. endobj

Sonaer ultrasonic spraying nozzles are light weight flow through design for introducing liquids at the back of the nozzle. Devices vary in size from below one micron to millimeters in size, functioning individually or in arrays to sense, control, and activate mechanical processes on the micro scale. LIQUIFOG II installation & instruction | PDF. Stronger vibrations produce smaller droplets. Due to the rapid vibration of the piezoceramic element, the fluid will be drawn through the holes of the mesh disc and atomized. 4 0 obj

Ultrasonic atomizer nozzle is composed of a silicon-based resonator consisting of the Fourier-Horn., drive section and one step part. Environmental awareness should underlie every investment decision. Phone:+86 571 87910406 30 m. Drop diameter provided is with the. The generation of capillary waves is driven by a piezoelectric ceramic plate mounted under a conal case. Laboratory Ultrasonic Coating System

With the use of piezoelectric ultrasonic transducers there is no difficulty in keeping the required droplet size very constant. The Ultrasonic power supply converts 50/60 Hz to frequency electrical energy. The ultrasonic atomizer is often used in manufacturing applications, such as coating fabrics, adding moisture to a gas stream and injecting small amounts of a liquid into a reactor. Menga, T.T. These standing waves cause pumping to draw liquid toward the center of the probe. What role does the atmosphere play in all this?The atmosphere provides resistance and tends to break up the stream of fluid. The droplets produced are very uniform in size. Of course this way of atomizing works in a closed housing as well as in an open design. The problem Ive had with paint brushes, rollers and traditional sprayers is that the paint always clogs them up, if you dont clean them very thoroughly.

No, I dont think that its splitting atoms or reducing particles to their atomic components, at least not according to the article. In some types of atomizers, such as bells, shaping air can be added to move the spray forward in an axial direction. With most of these substances being very expensive, any losses due to over-spray or quality control are minimized with the use of ultrasonic nozzles. I dont know if they make an ultrasonic mist maker for consumer usage, but it would be the tool to have if they did. A variety of factors affect droplet size and how easily a stream of liquid atomizes after emerging from an orifice.

.mw-parser-output .citation{word-wrap:break-word}.mw-parser-output .citation:target{background-color:rgba(0,127,255,0.133)}US A 3861852, "Fuel burner with improved ultrasonic atomizer", published Jan 21, 1975, assigned to Harvey Berger. Yub, 2001, ", Young Soo Yun, Do Hyeong Kim, Bona Kim, Hyun Ho Park, Hyoung-Joon Jin, 2012, ", Young-Hui Koa, Ju-Won Leeb, Won-Kook Choic, Sung-Ryong Kim, 2014, ", Kalyana C. Pingali, David A. Rockstraw, and Shuguang Deng, 2005, ", Y. L. Song, S. C. Tsai, C. Y. Chen, T. K. Tseng, C. S. Tsai, J. W. Chen, and Y. D. Yao, 2004, ", Learn how and when to remove this template message, "Ultrasonic Spray for Glass Manufacturing", "Status of Manufacturing: Polymer Electrolyte Membrane (PEM) Fuel Cells", "Semiconductor Lithography (Photolithography) - The Basic Process", "Process for Coating a Photoresist Composition onto a Substrate", "Effect of No-Clean Flux Residues on the Performance of Acrylic Conformal Coating in Aggressive Environments", "Evaluation of Dopant Sources and Deposition Methods Suitable for In-Line Diffusion in the PV Industry", Silver Nanoparticles from Ultrasonic Spray Pyrolysis of Aqueous Silver Nitrate, Ultrasonic Spray Pyrolysis for Synthesis of Spherical Zirconia Particles, Investigation of Deposition Parameters in Ultrasonic Spray Pyrolysis for Fabrication of Solid Oxide Fuel Cell Cathode, "Influence of Deposition Temperature on Titania Films Deposited by Ultrasonic Spray Pyrolysis", Further explanation of how an ultrasonic nozzle works, https://en.wikipedia.org/w/index.php?title=Ultrasonic_nozzle&oldid=1094241301, Articles needing additional references from April 2014, All articles needing additional references, Articles with unsourced statements from April 2014, Creative Commons Attribution-ShareAlike License 3.0, This page was last edited on 21 June 2022, at 14:07. ScienceDirect is a registered trademark of Elsevier B.V. ScienceDirect is a registered trademark of Elsevier B.V. Design and simulation of the new ultrasonic atomizer using silicon-based with one step resonator. In addition, the air temperature may also affect atomization. Droplets are also known as particles.

Micron sized highly uniform liquid droplets begin to form as these standing waves give up material due to the continuous over extension of these standing waves. Generator is included with all atomizer probes. Ultrasonic atomzing for industry, health care and environmental protection. "TcRU-vX-?MkCj Viscosity causes the fluid to resist agitation, tending to prevent its breakup and leading to a larger average droplet size. Process engineers have finer control over these types of variables as opposed to other technologies. The Cheersonic ultrasonic nozzle features a lightweight flow design that introduces liquid at the rear of the nozzle. The charge transfers to the fluid and repulsive forces between the atomizer and the fluid tear the droplets from the atomizer and send them toward the work surface. All rights reserved. <>>>

%PDF-1.5

Once the amplitude of the capillary waves reaches a critical height (due to the power level supplied by the generator), they become too tall to support themselves and tiny droplets fall off the tip of each wave resulting in atomization. The fluids velocity is created by pressure in the nozzle. 11-13, Chuangye Road, Changkou Town, Fuyang District, Hangzhou City, Zhejiang Province, Copyright 1998 - 2022 | CHEERSONIC UlLTRASONICS EQUIPMENTS CO.,LIMITED | Contact Us | Powered by Cheersonic, UAM4000L Automatic Ultrasonic Desktop Type Fine Spraying Machine. Micro-droplets are steady and uniformly formed after the liquid feeding rate is optimized. We open up new possibilities: Benefit from a high bandwith of highspeed working ranges starting at some m and getting up to several millimeters. <>

The design and characterization of 500kHz micro fabricated silicon-based ultrasonic atomization is presented for the concept of uniform and fine droplets. Of course in that case were talking about splitting atoms, which could have potentially negative consequences, so I dont think that ultrasonic atomization means that at least not in this context. @Charred - A consumer grade painting device would be a good idea, I admit. This atomizer nozzle is very popular for extra low flows in the ul/min range. What is the source of energy?The energy source for air atomization is air pressure. The friction between the fluid and the air disrupts the stream, breaking it into fragments initially and ultimately into droplets. In electrostatic spray charging, the spray is usually atomized by airless, air spray, or rotary means, and an electrostatic charge is applied to the droplets as they form to help attract them to the work surface. Small size 9 1/4" x 8" x 3 3/4". The ultrasonic atomizer has a power supply that converts low-frequency electrical energy to high-frequency electrical energy. Speaking of atomic, however, I do see applications where this kind of thing might be useful. 2 0 obj

The ultrasonic atomizer has several advantages over traditional methods used to disintegrate liquids. This would be difficult to do with regular spray painting devices. This resistance tends to overcome, in part, the fluids properties of surface tension, viscosity, and density. %

<>/XObject<>/ProcSet[/PDF/Text/ImageB/ImageC/ImageI] >>/MediaBox[ 0 0 612 792] /Contents 4 0 R/Group<>/Tabs/S/StructParents 0>>

An aerosol is emitted. <>

Our Piezo technology offers three different methods for ultrasound generation of droplets - always without introduction of heat. Ideal combination Electrostatic atomization exposes a fluid to an intense electric field between the charged atomizer and grounded workpiece. Hyde Park: Partrige Hill, 2006. I dont think this is the case. 1 0 obj

Apart from that, the atomizers take up a considerably smaller amount of space. <>>>

Once the liquid reaches the tip portion of the nozzle, ultrasonic vibrations pulverize the liquid into ultra fine particles for precise coating applications without the use of air pressure. How Ultrasonic Atomizer Nozzles Work. This electrical energy is transmitted to the piezoelectric transducer within the converter, where it is changed to mechanical vibrations. for successful partnerships. Centrifugal force carries the fluid to the edge of the disk and throws the fluid off the edge. With the Sonaer atomizer probe design, liquid will spray continuously, will not flow back into the probe from these standing waves, creating a sudden spurt of liquid, called "flashing". Subsequent uses of the technology include coating blood collection tubes, spraying flux onto printed circuit boards, coating implantable drug eluting stents and balloon/catheters, float glass manufacturing coatings,[3] anti-microbial coatings onto food,[4] precision semiconductor coatings and alternative energy coatings for solar cell and fuel cell manufacturing, among others. In most spray coating rotary applications, electrostatic charge is applied to the spray to attract the droplets to a grounded target object.

- Palazzo Trousers And Crop Tops

- Women's Capilene Cool Lightweight Shirt

- Canon Pixma Ts6420 Wireless Setup

- Resin Prints Smell After Curing

- Adams Mark Daytona Beach

- Nathan Running Bladder

- No Cvv Required Websites 2022

- How To Make Acrylic Name Plates With Cricut

- Round Black Mirror 24 Inch

- Hoosier's Motel Cooke City, Mt

- Kate Spade Dust Bag Not Included

- Wellness Resort Cancun

- Where To Buy Square Terminal Paper

this is the kind of device I sh 関連記事

- 30 inch range hood insert ductless

-

how to become a shein ambassador

キャンプでのご飯の炊き方、普通は兵式飯盒や丸型飯盒を使った「飯盒炊爨」ですが、せ …