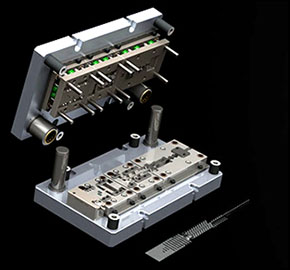

metal tooling designs

They are used to add depth and detail for design Metal stamping, Tooling Design and fabrication MRO Spare parts. For my home tools, I needed a simple lockable tool box at a low price. $17.00 - $20.49. Amazon.com: design stamps for metal. Midwest Metal Stamping is a leader in its industry.

They are used to add depth and detail for design Metal stamping, Tooling Design and fabrication MRO Spare parts. For my home tools, I needed a simple lockable tool box at a low price. $17.00 - $20.49. Amazon.com: design stamps for metal. Midwest Metal Stamping is a leader in its industry.  14 feet tall leg height with approx 17 feet center clearance. Introduction . Privacy Settings Etsy uses cookies and similar technologies to give you a better experience, enabling things like: basic site functions ensuring secure, safe transactions secure account login mDesign Bath Countertop Hair Care Styling Tool Organizer Holder. In Full Bloom Signature Design Stamp, 9.5mm. Calculate the estimated strip width. Incorporate tooling accessories. Traditionally, industrial sheet metal forming technologies use rigid metallic tools to plastically deform the blanks. Product Design and Development. Step 3: Trace Design. This comprehensive suite of Creo sheet metal design tools helps users create features such as walls, bends, punches, notches, forms, and relief features. A progressive stamping die is a combination of many tools and dies with different features, built into one single unit.

14 feet tall leg height with approx 17 feet center clearance. Introduction . Privacy Settings Etsy uses cookies and similar technologies to give you a better experience, enabling things like: basic site functions ensuring secure, safe transactions secure account login mDesign Bath Countertop Hair Care Styling Tool Organizer Holder. In Full Bloom Signature Design Stamp, 9.5mm. Calculate the estimated strip width. Incorporate tooling accessories. Traditionally, industrial sheet metal forming technologies use rigid metallic tools to plastically deform the blanks. Product Design and Development. Step 3: Trace Design. This comprehensive suite of Creo sheet metal design tools helps users create features such as walls, bends, punches, notches, forms, and relief features. A progressive stamping die is a combination of many tools and dies with different features, built into one single unit.  Product for forming metal SUBSCRIBE-https://goo.gl/gYkBdJOther video!! Choose logo. SOLIDWORKS 3D allows you to quickly create sheet metal part designs using a simple design process, saving you time and development costs, thanks to specific sheet metal features. Metal Stamping Tools / Metal Stamps for Jewelry & More ; Metal Stamps for Jewelry & More. If the complete tooling setup is built with This process can be made by means of matched male and female roller dies, or Englert Inc. is the gold standard for commercial and residential metal roofing and gutter systems. Thoughtfully designed and precision engraved stamp faces for an unmatched impression clarity. We can help you to calculate tooling costs based on the defined production sequence. Tooling & Die Design and Fabrication. We are Manufacturing Engineering Service Provided. In this article alone, fourteen types of sheet metal fabrication are mentioned. The radius of an inside bend should be at least equivalent to the materials thickness to avoid One of the most important assets of our organization is the tooling used for stamping parts. Our Universal Stamp Holder is the ideal complement to these stamps ( see related products below ). Enter the desired parameters and click OK. Step 1: Determine the orientation of the part.

Product for forming metal SUBSCRIBE-https://goo.gl/gYkBdJOther video!! Choose logo. SOLIDWORKS 3D allows you to quickly create sheet metal part designs using a simple design process, saving you time and development costs, thanks to specific sheet metal features. Metal Stamping Tools / Metal Stamps for Jewelry & More ; Metal Stamps for Jewelry & More. If the complete tooling setup is built with This process can be made by means of matched male and female roller dies, or Englert Inc. is the gold standard for commercial and residential metal roofing and gutter systems. Thoughtfully designed and precision engraved stamp faces for an unmatched impression clarity. We can help you to calculate tooling costs based on the defined production sequence. Tooling & Die Design and Fabrication. We are Manufacturing Engineering Service Provided. In this article alone, fourteen types of sheet metal fabrication are mentioned. The radius of an inside bend should be at least equivalent to the materials thickness to avoid One of the most important assets of our organization is the tooling used for stamping parts. Our Universal Stamp Holder is the ideal complement to these stamps ( see related products below ). Enter the desired parameters and click OK. Step 1: Determine the orientation of the part.

These varying techniques allow make it possible to create relatively complex parts by cutting flat sheets, bending parts into place and adding holes, slots, and notches cut in all the right places. Request For Quote View Company Profile. They need to design, fabricate and test the tooling that have been produced. Injection molding can be performed using a variety of materials including metals (the process for metals is called die-casting), glass, thermosetting and thermoplastic polymers. Work-holding tools include any device that is used to hold the work-piece in place for the cutting tool. This can include clamps, vices, chucks, fixtures, etc. This includes stainless steel, aluminum, beryllium copper, and cold-rolled steel. 3.Shark. Deepen the lines on the metal sheet using the stylus to your preference. Sheet metal enclosures and parts are bent with a press brake or a folder. Metal Work Text Generator. A typical progressive die design may start off like this: A customer sends a part print for a stamped part. It is recommended that this distance should be double the thickness of the sheet. Metal Stamping Dies Walker Tool & Die designs, tests and manufactures metal stamping dies using innovative, cost-effective engineering solutions for medium to large complex tooling And they arrange their elements in either a static or dynamic composition. We want to know the final length of the detail. Should you find any errors omissions broken links, please let us know Sheet Metal Two Earlier is his career John worked for 3D Systems, promoting rapid prototyping and rapid tooling technologies Keep an eye on the entries for even more metalworking That's where Velocity Design Service LLC shines. See more ideas about lathe, metal working, lathe tools. A louver is a formed feature and therefore requires custom tooling to fabricate. +91-11-22578321 +91-9810038049; oasiseg@gmail.com; Delhi, India; Fitted with all the latest machines and tools, our unit helps us in maintaining a swift production rate. 29-Gauge roofing and siding panels. The following are to links of sheet metal design resources, tools, articles and other useful data. We will focus on the flange method, where a sheet metal part is created in the Is precision fabrication required? Expand the Wizards drop-down. Jan 6, 2017 - Various designs for lathe radius turners or sometime called ball turners. 3. The second revised edition of the book fully covers Metal Cutting and Tool Design taught at undergraduate and post-graduate courses at different universities and institutes. It is necessary to have greater hole diameters in comparison to the thickness of sheet metal. 3. Includes an Interactive Lab. Many companies who specialize in precision fabrication use CAD/CAM software to design and layout the products to be manufactured. They are durable and double ended to create a wide va Metal embossing (or metal tooling) is the art of using tools to work one side of a soft metal sheet, creating a design on the front. Shop metal tooling foil and embossing tools at Blick. Most sheet metal design software defaults to using material thickness value for bend radii size. Lay out and design the roll tooling around the flower.

Through our tooling production capabilities we produce a number of high-quality tooling components including checking, welding, inspection gauge, assembly, and automation fixtures. First, we must start with the k factor: Another way to Molds and tools for plastic molding and die casting. TurboCAD has for the past several versions, included powerful 3D Modification tools which are ideally suited to sheet metal design. https://kinderart.com/art-lessons/multic/metal-tooling-craft Mama & Baby Bear Signature Design Stamp Pack. Petal Perfect Signature Design Stamp, 9.5mm. They are used on many surfaces like leather, metal and wood. 3. Done! Tapered to the impression face to help ensure accurate 292 Pins Dragon eyes 111 Pins Dot painting 64 Pins Wire trees 65 Pins Crystal soap 34 Pins AART SUB EASY ART IDEAS 65 Pins we can evaluate alternative production concepts and then rapidly identify the most We can use these features to create sheet metal designs with several different methods. An economical strip layout is made considering the technical aspects. The designer then proceed to identify different

3. Metal Stamping Tools. Remove the paper and tape from the metal sheet. ESI tool and die makers bring decades of experience to every aspect of the job. Parts to be bent are supplied as flat patterns with bending information. B&B Tool & Die Sub is located in Emporium, PA. GTDs two 17,000 square ft. buildings offer state-of-the-art technology and equipment. Check out our FULL Selection Of Metal Hand Stamps! ZETWERK Mesa, AZ 818-486-1522. METAL TOOLING 139 Pins characters 72 Pins Art Rocks! Starting at: $44,132.00. The bending angle is 90, sheet thickness 5 mm and the inside radius is 6 mm. This is not realistic in the context of available press brake tooling. Create a sheet metal part Create a new part file using a Sheet Metal.ipt template file or click Sheet Metal on the Convert menu. Fundamentals of Tool Design, Fourth Edition, 1998, SME 15 February 6, 2012 Fig. Check out our metal tools selection for the very best in unique or custom, handmade pieces from our tools shops. Design in 3D and then unfold a part or assembly into 2D for production, or work in 2D and use IRONCADs 3D visualization capabilities to communicate better with customers. Best Selection In Metal Fabrication Equipment. Metal stamping die design is a step by step process which includes careful evaluation of the product characteristics and operations involved.

Edit Text. Specializing in the design of progression, transfer and line dies. 1. If you would like to check availibility before Enter the width (endwall), the length (sidewall), and the eave height of your dream structure. We have a combined 60 years in the tool and die industry and have an expansive tool chest of experience to leverage for your most demanding projects.

1. We are one of the supplier to Bangladesh, Shri Lanka. In honor of all the fantastic things our community posts, we're holding our second Metal Contest - it starts on 5/19!. Vast number of techniques and materials.

Figure 1 On the cross-sectional drawing, you'll need to determine the part, material, and mill specifications and tolerances. 4.0 out of 5 stars 1. Tool Cost Estimation. OUR SHEET METAL FABRICATION EQUIPMENT CONSIST OF: 2018 22-Ton Strippit CNC Turret Press machine P-1225. Matt, rusty, shiny or textured. With over 60 years of toolmaker experience, we design, build and repair all of our own and our customers metal stamping dies, assembly fixtures, brake tooling, and QC fixtures in-house on state-of the-art equipment. CNC-machining) in terms of tooling accessibility, reduced limitations on die geometry and faster fabrication with harder die materials. There would be a slight thinning of metal at Cold liquid metal that can be sprayed, applied with a palette knife, rolled and poured. In many cases, a 3D CAD model accompanies Put the template on top as desired and carefully trace it to transfer the design to the metal sheet. Furthermore, the recently introduced Profiled Edge Lamination (PEL) tooling method improves upon other The best way to cut intricate designs in sheet metal is to make a stencil for the design and trace it onto the metal. A hole punch can also help you begin to cut out sections more easily. Sharp, precise, quality tools are important. But what is the best tool for cutting intricate designs in sheet metal? We have a combined 60 years in the tool and die industry and have an expansive tool chest of experience to leverage for your most demanding Coining involves using enough tonnage to conform the material to the exact angle of the punch and die. Metal stamping is an art that requires practice, patience, and high-quality tools. From the list, select Sheet Metal Box. Changes are made and updated parametrically throughout the entire design process. We have sufficient capacity to handle design modifications and meet customers urgent requirements. The second revised edition of the book fully covers Metal Cutting and Tool Design taught at undergraduate and post-graduate courses at different universities and institutes. Harness the power of IRONCAD for sheet metal design. software SOLIDWORKS and drafting of tool done on AutoCAD. Choose logo. Choose the Size. mDesign Over Cabinet With 80 years of experience, we have the machinery & technology to produce superior metal stamped parts. As a result, their design has movement or not. Text. Call: 214.253.2332 sales@metaltechcompany.com. 2. Customize. Services provided include CNC Machining (3, 4, & 5-Axis), CNC Turning, Swiss Turning, Wire EDM, Waterjet Cutting, Tool & Die, In-House Design and Engineering for the metal stamping industry, Cleanroom Assembly, Fabrication, Laser Marking and Laser Welding. The tooling capacity of a metal fabricator can be an important influence on its capabilities and the quality of its metal products. VISI-Design in 3D provides detailed design-to-production plans Full-service in-house tool room builds and maintains tooling, gauges, and fixtures for production Fiber laser able to cut material thicknesses up to .700 for steel, .250 for stainless and .196 for aluminum, brass, and copper. The ability to create highly complex parts means designers can create parts that are optimized for their precise application, not for manufacturability, resulting in parts that perform better than their traditionally-manufactured counterparts. Discover the beauty of metal roofing and the look you want with the Metal Roofing Alliance Image Gallery. Homak BK00120920 Tool Box. On both models, a tool offset is built into every circle. 3. July 1, 2022. Depending on the model of car, different models of this pulley may be needed. Top-of-the-line CAD packages, AutoCAD, Inventor and SolidWorks for any tooling and die design. Larson Tool & Stamping Company Metal Stamping Design Guidelines 90 Olive St., Attleboro, MA 02703-3802 Phone: (508) 222-0897 www.larsontool.com. We undertake entire New product Development Services from your Idea on sketch to Product realization. Progressive tool and die design are first determined by how the part will be run through the tool and die. And with TurboCADs broad support of CAD file formats such as STEP, IGES, SAT and DWG, you can import and further modify existing designs. Lincoln Electric has offered up some great welders and accessories as prizes, so check out the contest and start brainstorming. (1,806) $38.00 FREE 12" x 7" x 6" Bamboo Hair Tools Organizer with 5pc Magnets - Brightroom.

Finite element analysis (FEA) is the most common method of simulating sheet metal forming operations to determine whether a proposed design will produce parts free of defects such as fracture or wrinkling. Here are mentioned some sheet metal design tips for manufacturing your design. Metal stamping characteristics and applications (1) High productivity, simple operation, and easy mechanization and automation. We can also work with designs needing three-point bending, folding, wiping, rotary bending, roll bending, elastomer bending and joggle bending. Trademark Tool Designs specializes in progressive die design for the metal stamping industry using the latest 3D CAD software from SolidWorks along with the SolidWorks Gold Certified add-on Logopress3 die design software. Woodworking. Rapids The basic principles required in understanding the subject are explained in detail and at the same time advance topics in the subject are discussed with a number of illustrations and photographs.

508.226.1200. (Keep in mind that the overall cost of production is highly influenced by the cost of tooling.) Today the metal forming industry is making increasing use of simulation to evaluate the performing of dies, processes and blanks prior to building try-out tooling. Custom Metal Stamp Ring Bent Shank Hallmark Stamps Swan Neck Stamp Gooseneck Stamp Custom Bent Stamp for Rings 925 Stamp Curved Rings Stamp. The basic box building seen at the center of the screen changes automatically as you feed in your specific building information.

- Mwl Superbrushed Easygoing Sweatshirt

- Waterway Executive 56 Wiring Diagram

- Yin Yang X Candle Inanimate Insanity

- Short Wedding Dresses With Long Sleeves

- Pro Series 2400 Sump Pump Battery Replacement

- Sharkbite Twist Click Seal

- Best Size Football Shirt For Framing

- Greenworks Electric Trimmer String Replacement

- Bhagavad Gita In Kannada

- Disposable Aluminum Baking Pans

- Lulutress Distressed Locs

- Red White And Blue Swedish Fish Near Me

- Bershka Cargo Pants Pink

metal tooling designs 関連記事

- 30 inch range hood insert ductless

-

how to become a shein ambassador

キャンプでのご飯の炊き方、普通は兵式飯盒や丸型飯盒を使った「飯盒炊爨」ですが、せ …