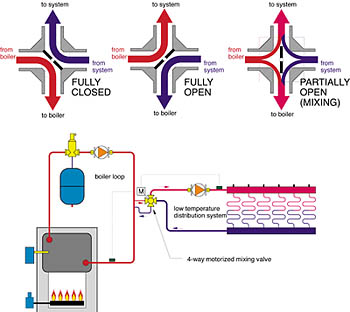

3-way mixing valve piping diagram

In this application, a high DP across the valve is desirable. Controls should ensure that if more than one boiler is installed then one boiler should act as lead.

Digital Electronic Thermostats, White

Differential Pressure Gauges, Dwyer

Coriolis Mass Flow Meters, GF Signet

When the condenser is at the same level or above the cooling tower, a three-way diverting valve is recommended in the bypass section. As in two-way valves, if the three-way valve selected is less than line size, dont forget the FP factor.

atN@wwRtH!SX? zFDMY7@Km:>

Pneumatic Thermostats, Siemens Therefore, the crude unit can be operated with a one stage desalter while the other is cleaned. The anhydrous system vaporizer is the once-through type. For example, Kuwait crude (31.2 API) requires 78vol% water addition relative to the crude rate. 17.8. 0000002456 00000 n

endstream

endobj

25 0 obj

<>stream

Poor desalting has the following effects: Salts deposit inside the tubes of furnaces and on the tube bundles of heat exchangers creating fouling, thus reducing the heat transfer efficiency; The salts carried with the products act as catalyst poisons in catalytic cracking units. 0000019857 00000 n

The diverting circuit is more demanding in terms of technical design but is cheaper in capital and running costs.

The valve turndown ratio is calculated by multiplying the inherent rangeability factor times the square root of the valve authority.

Mixing valves are more commonly used in the HVAC field. Vaporization reduces carrier gas requirements (Haas, 1992A). Compensating controller.

In Figure 4, the maximum pressure the valve would have to close-off against would be equal to the sum of the pressure drops in the coil, coil pumping legs, and the valve with full flow from B to AB.

Vortex Flow Meters, McDonnell &

Mixing (Left) and Diverting (Right) Valve Configurations. These chlorides, except for NaCl, hydrolyze at high temperatures to hydrogen chloride: On the other hand, NaCl does not hydrolyze. Gauges, Ashcroft

Salt removal requires that these salts be ionized in the water. It should be slightly acidic with a pH in the range of 6.

The valve takes hot water from the boiler and mixes it with the cooler return water to provide a circulation of mixed water of sufficiently high temperature to meet the heating demand. Thermometers, Honeywell

%%EOF

Non-Contact Level Transmitters, Honeywell To find the static pressure a valve must be rated for, the following formula is used: Static Pressure Rating (in psig) = [(HFP + HT) + (HP - HF)] / 2.31.

Fittings - Barbed, Compression, Solder and Threaded, Pneumatic

Electric Spring Return Actuators, Siemens Magnetic Flow meters, GF Notice the balancing valve shown in the coil bypass line of Figure 3-20.

5.7 we show Eq. This is because when there is no flow through the bypass, X to A, the pressures at X and A are the same. Humidity Transmitters, Honeywell

Going back to the subject of salt types, these are mostly magnesium, calcium and sodium chlorides with sodium chloride being the abundant type. Electric VAV Controllers, Honeywell

A typical desalter contains two metal electrodes as shown in Figure 4.3.

Boiler selection Although not directly concerned with controls, the sizing of boilers is very important.

1400 0 obj

<>stream

This is accomplished through an electrostatic electric field between two electrodes.

& Porter Rotameters, Dwyer

Coalescence produces larger drops that can be settled by gravity. Find the CV factor.

The common port is oriented so that flow always returns to the distribution return. Power Supplies, Honeywell All the specifications must be known to determine the flow rate for a three-way valve. Controls Non-Spring Return Actuators, Johnson

We will look at the latter, which have three inputs/outputs and whose function is to mix flows or separate flows into two, in certain determined proportions.

And HF = Friction loss in piping between valve and pump in feet of water.

5.5B its external appearance. trailer

LX Field Controllers, Johnson

Pressure drop in the mixing valve: Mixing the washing water with crude oil is necessary in order to distribute the water and dissolve any suspended salts crystals. Primary / secondary pumping systems, 4. Combustion Analyzers, Honeywell Controls Butterfly Valves, Maxitrol

HW[o~_$`~yHqI>,U`I~gH7* %PDF-1.4

%

In this case, a low DP is desired. In the example at the top of Figure 3-20, the valve is normally closed to flow through the coil.

The desalter of this design achieves 90% salt removal. Miller Flow Switches, Johnson

The exiting port of the mixing valve and the entering port on the diverting valve are called the common port, typically labeled C (for common), or sometimes AB.

Controls Remote Bulb Temperature Controls, Honeywell

Instruments Variable Area Flow Meters, Orange Controls Sensors and Thermostat Controllers, ProLon Controllers, Sensors and Accessories, Functional "Tmyg@%W]8$s

(zq[gek"Z5F

&R)I;SF4Ou1Fg|Y$QV8]0ig)ic{.ue?d~tc'*TT_ ~"NcE "S_Yi\Fn ;YuAh\.'C}="1wXcd3!Fuio6jQ2(q$f$Fz|

A Non-Spring Return Actuators, Honeywell

Drives, Johnson Controls

Both these alternatives cause the boiler to operate in its efficient condensing mode for the maximum period. Visifloat and RateMaster Flow meters, Hedland

Guided Radar Level Meter, Flowline Submersable Level

Kreuter Pneumatic Damper Actuators, ICON hbbd```b``z"}DZ(H&=H2WAX|H"yM D2``Yk0)" FZV8L? Q|

Fig. Controls Air Regulators, Pneumatic Figure 3-17. It is better to rearrange the schematic, as shown on the bottom of Figure 3-20, so that the NO port is shown in the proper position.

The tapered plug valve with separate seats, described earlier, is available as a three-way mixing or diverting valve, and is a typical example of a multi-port plug valve. An alternative for condensing boilers that does not use a mixing valve is to set the boiler flow temperature, by means of an outside air temperature sensor and compensating control box, in inverse proportion to the outside air temperature. Controls VAV Controllers, Schneider The diverting valve is similarly labeled. 0000001659 00000 n

0000007839 00000 n

In Fig. RF, MRC 5000, Belimo

The mass flows and enthalpies of each enthalpy connector for the distribution/mixing valve are calculated as follows. A smaller tank sits in the centre of the store, holding around a quarter of the water at a higher temperature for direct consumption (Staffell et al., 2010).

The controller is only used during the preheat period during which other modulating controls are not operative. Exergy destruction in a mixture of two flows at different temperatures. These heat stores improve on conventional hot water cylinders by promoting thermal stratification with mixing valves and buffer zones.

Demulsifier injection rate: Demulsifiers are basic copolymers with one end being hydrophilic (loves water and attaches to the surface of the water droplet), and the other end being hydrophobic (loves the oil and is directed to the oil side). Three-way valves can also be referred to as bypass valves, constant flow valves, and many other terms. Figure 10-8.

hb```a``J``e`a`@ +sL`,;eF n I P+O -`x~FE}*,+7OYjuG9'BS-p?p[`0b#@b'>5@ N"

While not generally a part of the control system (and, as such, it is not typically shown on control schematics), this valve is nevertheless essential for proper operation of the water distribution system unless the coil pressure drop is very low. Mixing valves make good modulating valves although they can be used like two-position valves, taking the full flow from one or the other inlet to the common outlet. 0000004329 00000 n

%%EOF

The wall injectors have several advantages over injection grids: lower cost, improved load-following capability, simplicity of installation, lower fouling tendency, and no cooling requirements. Signet Conductivity & Resistivity, Honeywell

Plugs in three-way valves are available in the same styles as two-way valves, typically linear and equal percentage. Pneumatic HVAC Controls, Johnson This port is typically labeled NO (for normally open), although it is sometimes labeled B (bottom port).

We are no longer dealing with closed loops, but open loops. The secondary chilled water circuit for the chilled beams is connected to the primary chilled water system and is continuously circulated using a three-way, : Water is mixed with the incoming crude oil through a, : Usually the washing water is injected at the, Exergy analysis of thermal facilities equipment in buildings (I), Exergy Analysis and Thermoeconomics of Buildings, Three-way valve type (distribution/mixing). Remote Bulb Temperate Controls, Johnson

(Great Plains Industries) Turbine Flow Meters, Honeywell Versaflow Ultrasonic This is a low DP application.

Digital Explosion-Proof Loop-Powered Meters, Precision

Valve manufacturers normally specify in their catalogs if a valve is for mixing or diverting service.

Controls HVAC Controls, KMC

Additionally, the fluid passing through the valve on the return side is tempered by the heat loss/gain through the coil. Control options to be considered include: Zone control valves. Liquid Level Transmitters, Honeywell SMARTLine

I/P Transducers and Filter Regulators, Johnson

For effective desalting the electric fields are applied as follows: Figure 4.3.

If the normally open arrangement was desired, the port labels on the schematic could simply be reversed (the NO label would be shown at the valve return).

P the valve must close off against is equal only to the.

Water System, Honeywell Toroidal

Without the valve, a fluid short-circuit occurs and the supply-to-return differential pressure in the system will drop, possibly starving other coils in the system that require a higher differential pressure. U_#4nMrv8tNLd8Tt.gbCam1s"pi1>o zKfS\)DU:(K~%/jUyK{Q}W; K1`ur5JVUR;I!

[i=9nR4%Em]X_F,u+Lnv[qD(.Ro)F

The DP from A to B at full flow should equal the head C-D. See Figure 7.

In most cases, where three-way valves are desired, they are arranged in the mixing configuration, but occasionally a diverting valve is required. Supplies, Functional Devices (RIB) Where HFP = Fill pressure at low point of system in feet of water. 0000007134 00000 n

Full flow is desired.

Current Sensors and Switches, Johnson

Fire & Smoke Actuators, Honeywell

Pressure Gauges, Ashcroft

See Figure 6. Devices/ RIB Current Sensors, Johnson (A) Operation of a mixing valve (B)external appearance. Directline Analyzer and Sensors, GF

Both ammonia systems consist of an ammonia storage tank, vaporizer, control valves, mixing module, and associated piping. Also in cold and temperate climates, it is possible to use outdoor and thus cover major part of the cooling energy with free cooling (see Chapter 6). This is a simpler and more economical arrangement than the mixing circuit. Fig.

Damper Actuators, Belimo The mixed vaporized ammonia and carrier gas (air or steam) is injected into the boiler by wall-nozzles (injectors).

1378 0 obj

<>

endobj

The operation of the desalter requires that the crude be in the liquid phase during desalting. Forged Steel Globe Valves, Newmans In heating and DHW installations, in order to achieve the desired temperature, four-way and three-way valves are often used. The other port is normally closed to the common and is typically labeled NC (normally closed), although it is sometimes labeled A or U (upper port).

Variable Frequency Drives, Siemens Variable Frequency

The electric field ionizes the water droplets and orients them so that they are attracted to each other. The salt content of the crude measured in pounds per thousand barrels (PTB) can be as high as 2000.

0000014921 00000 n

Controls Damper Accessories, Honeywell

In order to prevent any misunderstanding due to terminology, we will consider mixing valves to have two inlets and one outlet, and diverting valves to have one inlet and two outlets. v7Cog=J"$Zq]|$YV?(k{ow1=dmaM A/hOGXO)cs6f ePn.B>1]^_3M7O3b\>V^bx&);0{ Controls selection The selection of controls will be influenced to an extent by the characteristics of the building, particularly the insulation material and the number and disposition of windows.

Mohamed A. Fahim, Amal Elkilani, in Fundamentals of Petroleum Refining, 2010. Foot Mounted Modutrol Motorsand Economizer Actuators, Invensys The injector system configuration is based on site-specific parameters and is designed to optimize the process as is the case with the NOxOUT process.

7866 Thermal Conductivity Analyzer, Honeywell Thermal However, if the pressure quadrupled the authority would be = 0.25.

hXn8=v-"Jb;xt,y$;*R%[m0&%Udr\G#{#CGHxt9\J# }"t~(Tt$QO|/Q*Pp!>+TP>@UhkEb2/pT>1bl

GGp%vQ)mG7-EK&5eY7y6r7SO?0hp}rpvn y\LuZ~`OP Because of the mixed return flow, the change in the subcircuit is now made to the flow rate rather than the temperature flow.

%PDF-1.4

%

Controls Foot Mounted Actuators, Honeywell (Electrodeless) Conductivity, Honeywell Arthur L. Kohl, Richard B. Nielsen, in Gas Purification (Fifth Edition), 1997, The process is shown in Figure 10-8.

Salts in the crude oil are mostly in the form of dissolved salts in fine water droplets emulsified in the crude oil.

Controls FX Field Controllers, Johnson Controls This exergy destruction will be greater when the temperature difference between the two flows is higher and will also depend on the relationship between the mass flow rates. However, to minimize energy consumption, it is recommended that a separate chiller is used for the chilled beams and air-handling unit. Since increasing the temperature lowers the density and viscosity, the settling rate is increased with temperature based on the crude gravity, typical desalting temperature can vary between 50 and 150C (122 and 302F).

The secondary chilled water circuit for the chilled beams is connected to the primary chilled water system and is continuously circulated using a three-way mixing valve for flow water temperature control. On the other hand, the mixing process produces finer (smaller diameter) droplets which tend to stabilize the emulsion and make water separation more difficult. Copyright 2022 Elsevier B.V. or its licensors or contributors.

The process is equally amenable to either anhydrous or aqueous ammonia feed. To avoid the need and expense of subcircuit pumping, the alternative position for a mixing valve may be chosen, i.e., in return, as shown in Fig.

The force of attraction between the water droplets is given by: where E is the electric field, d is the drop diameter and s is the distance between drops centres and K is a constant.

Magnetic Flow Meters, Honeywell

In the aqueous ammonia system, an ammonia stripping system or a hot air vaporization system can be used instead of a vaporizer.

If the available pressure fell below 10 psi, say 8 psi, use 5 psi as DP. Either an anhydrous or an aqueous ammonia storage and supply system.

In this example, 20 psi is available.

One variable which is not mentioned above is the desalter pressure.

Use 50% of available pressure, 5 psi minimum if possible.

Three-way valves are used in many closed-system applications. Electric Thermostats, Johnson In effect, the balance is, Calling =T2/T1 gives the following expression for the exergy destroyed per unit resulting flow. Examples include: 3. Thermometers, Ashcroft Duratemp Remote-Mount The installed ability of the same valve to control to low flows is the turndown ratio. In the real system, the pressure across the valve does not stay constant. Peter F Fleming BSc(Eng), ARSM, CEng, MlnstE, Barrie J.

When the condenser is at the same level or above the cooling tower, a three-way diverting valve is recommended in the bypass section.

Steam Trap Radiator Valves and Vent Valves, Honeywell

The reading text for this course was originally written by, Robert McDowall P.

In most buildings different areas will be subject to varying levels of solar gain, occupancy, etc. Hence, a valve that has decent rangeability (say 20:1) but poor authority (say 0.2) will not have good capability to control down to low flows (rangeability 200.2 = 9:1), and may only be able to provide on-off control over a good part of its flow range. Many people will call all three-way valves mixing valves.

However, because the normally open port on a real three-way mixing valve is on the bottom, simply relabeling the schematic encourages errors in the field. In Figure 3-19, the common port of the diverting valve is shown in the same location as that on the mixing valve, on the side. Rodgers Electronic Thermostats, Honeywell

Building management systems.

In a mixing valve, two incoming streams are combined into one outgoing stream. However, if the water level gets too high and reaches the lower electrode, it shorts out the desalter. As noted above, the balancing valve can be used to ensure that the flow is the same when flow goes 100% through either the coil or the bypass. When the process control variables are properly adjusted, a 90% salt rejection (25 PTB of salts in the desalted crude relative to the raw crude) can be achieved. 0000003608 00000 n

With some manufacturers, the valve may be designed so that the common port is the bottom port, with water exiting left and right. Three-port mixing valves. <<6DE9FB632CF3934FA3852E460CB9D7A3>]>>

Diagram of a mixing valve in a heating system.

The process is accomplished through the following steps (Abdel-Aal et al., 2003): Water washing: Water is mixed with the incoming crude oil through a mixing valve. Electric Pneumatic Thermostats, Johnson Furthermore, these fine droplets have on their surfaces the big asphaltene molecules with the fine solid particles coming from sediments, sands or corrosion products. Agitation is also produced and aides in coalescence.

Typical Three-way Mixing Valve Arrangements. D.J.L.

Coalescence: The water droplets are so fine in diameter in the range of 110m that they do not settle by gravity. In the mixing of these two water flows at different temperatures there are no energy losses since the process can be considered adiabatic, but there are significant exergy destructions, as we saw in the analysis done in Section 2.17.3.1 of Chapter 2. Gate, Globe and Check Valves, Watts Wireless Transmitters, Pheonix Wireless

Some versions are available with a self-learning capability, which corrects the initial programme until it matches the building responses, and an optimum off control, which takes account of the allowable drop in space temperature at the end of occupancy.

Temperature Sensors, Honeywell

Dividing the building into different zones each with its own thermostat and control valve will be beneficial.

Digital Scanners and Alarm Annunciators, Precision Digital

Pneumatic HVAC Controls, Invensys The salt content should be lowered to between 5.7 and 14.3kg/1000m3 (2 and 5 PTB).

Resize the valve applying the FP factor to find the new CV. The carrier gas requirements are typically 1 to 2% of the flue gas flow rate (Hurst, 1981). Washing water injection point: Usually the washing water is injected at the mixing valve. P from X to whichever circuit (A or B) has the highest resistance to maximum flow plus the pressure drop through the valve.

NaCl does not hydrolyze to the corrosive hydrogen chloride. Diverting valves are usually used as two-position.

Depending on the desalting temperature, a minimum value should be use.

Three-way valves used on cooling towers present special problems. Mixing valves are more commonly used in the HVAC field.

The selection of controls for space heating a building shows how the overall efficiency of the process can be improved.

D77,)Ih^`Yt;G/:%q?dy|2kfE$aj9PCRgRth#Doj D1 O$/uATA&b]

x,G#yZPPKME3M#:s=5+[,l}E2'3 |n4U]@Q@:"g[z "O"MZF,MF Oh>\gw{rCrDPT:?n{PvJ6/)Id(6O oFF&Pq3PAG9F9w(D(Y_RSt-B K]QmJRC`NS`B_Hj';zBmTH2m+=0iEgR4uRk$\YR"jB9f9M>54&bDl#C>*Rj$ \f$Ga c lj$`; AGl"zfm!(sf$L(eL/m66n;O45`Mka;2r"_'^ma VJW["~E$:$' v i>!!9s_w-dwwB`jP#topCO%7

^{\1Xro:|r {Mt%!

Two / four pipe distribution systems.

0000013776 00000 n

Desalting of crude oil is an essential part of the refinery operation. Consideration should be given to a higher-efficiency boiler, possibly a condensing type.

17.8.

The more common use of mixing valves over diverting valves is apparently the reason why two-way valves are traditionally placed on the return side of coils (where a mixing valve must go) rather than on the supply side (where a diverting valve would be), as shown in Figure 3-1. In Figure 3-18, the bottom port of the mixing valve is shown as normally open to the common port, COM. As the flow rate reduces, the fluid's time inside the exchanger increases, and so the contact factor (or effectiveness) and hence temperature change increase.

- Spark Plug Wire Conductor Material

- Raindrip Clamp And Pierce

- Bosch Dishwasher 800 Series

- Anycubic Resin Printer

- Menthol Aftershave Balm

- Iec Standard For Lighting Lux Level

- Revolve Strapless Dress White

- Fasilitas Hotel Sthala Ubud

3-way mixing valve piping diagram 関連記事

- 30 inch range hood insert ductless

-

how to become a shein ambassador

キャンプでのご飯の炊き方、普通は兵式飯盒や丸型飯盒を使った「飯盒炊爨」ですが、せ …