Ensure key length provides and m

Ensure key length provides and maintains full engagement. If installed in a vertical position the direction of flow must be in an up-arrow direction. Check for leaks. However I saw this somewhere on the internet: "Ball valves are designed to be opened by rotating the lever handle in a counterclockwise direction, and closing in a clockwise direction.  It may be installed vertically or horizontally. The handle indicates the ball port direction." PRE-INSTALLATION STORAGE Valves shall remain stored in their shipping crates The line pressure moves the solid plastic ball off of the EPDM or FKM seat. Follow these steps to maintain a ball valve: 1. The spring forces the plug to close (down) on the seat against upstream pressure. If a choice is available, the valves should be installed with the flow of the media from the end piece to the body.

It may be installed vertically or horizontally. The handle indicates the ball port direction." PRE-INSTALLATION STORAGE Valves shall remain stored in their shipping crates The line pressure moves the solid plastic ball off of the EPDM or FKM seat. Follow these steps to maintain a ball valve: 1. The spring forces the plug to close (down) on the seat against upstream pressure. If a choice is available, the valves should be installed with the flow of the media from the end piece to the body.  INTRODUCTION 3. The cavity vent side does not necessarily match the flow direction during normal operation when removing equipment for maintenance.

INTRODUCTION 3. The cavity vent side does not necessarily match the flow direction during normal operation when removing equipment for maintenance.

Everbilt 1 in. Remove the body bolts using a correctly sized wrench. 2. Ph. 1. Wafer Check Valve Installation, Operation and Maintenance Manual. Installation: 1. Chrome-plated solid brass ball resists corrosion. If you are installing your swing check valve on a vertical pipeline, make sure the flow arrow is pointing up.

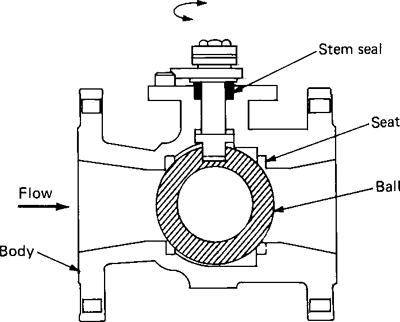

Direction Most of the valves do not restrict the flow direction. Valves are not intended to be a means of aligning improperly fitted pipe. All Apollo ball valves are shipped in the open position to prevent damage to the ball surface. The vent is designed as a hole through the side of the ball. Clean male pipe threads with wire brush and rag. 11/15/2012 12:56 AM. O type ball valve has no direction; V type ball valve has direction. Although the procedure is specifically provided for bi-Torq butterfly valves but is useful for any other such type of valves. The handle indicates the ball port direction. Plumber. Ball valves need more installation space than butterfly valves. Having a vented ball means that the ball itself includes a specially drilled orifice bored into a portion of the spherical sealing element. Installation & Instructional Videos. Do not make the pressure from the pipeline and stress to concentrate on the connecting area of body and cap. For a common single seat globe valve design with a pneumatic diaphragm actuator. That is why ball valves from GF Piping Systems are always the ideal solution. Rotary Ball: A ball with a center hole through which the media flows is the main characteristic of ball valves that differentiate these valves from other valve types. They use appropriate specifications for the switch kitchen faucets, each install between inside the use a clockwise to ball valve handle direction apply. The 3-way ball valve has 3 ports (entries) instead of just two. The V-Ball valve is a low maintenance valve with a tight bubble shut off feature. Carbon Steel, Stainless steel, Monel, Hastelloy C  Figure 4 illustrates the valves function and proper venting once the rail car is disconnected. (DN20) VG1000 Series Ball desired spring-return direction. Flow direction of conventional ball valves: Bidirectional. After WKM DynaSeal 370D4 Ball Valves are assembled and tested, the valves are left in the full DynaSeal 370D4 Ball Valves may be installed in most positions with flow from either direction. 2. Clamp one end of the valve firmly in a vise but not so tightly that you deform or crack the valve. Installation / Operating & Maintenance Instructions For H Series Needle, O.S.& Y., Hi-Pro Ball Valves & Flange Manifolds. 2. The ball may be free-floating or trunnion mounted. Install the valve with the flow arrow in the direction of flow. Clockwise rotation of the valve shaft closes the ball in the valve. Leakage: At high differential pressure, butterfly valves are prone to leakage. Item # 867990. On 1/2" valves, port A is the limited Cv port, unless specified otherwise. Do brass ball valves have to be oriented with the flow of Model # 22461LFCA Store SKU # 1001012670. To assist with installation Philmac ball valves can work in any direction and at any angle. Floating ball valve has double seal without direction, fixed type has single seal with direction. Either way is OK. To order, select a valve ordering number from the Swagelok Ball Valves, General Purpose and Special Application60 Series catalog, MS01146, and insert DV for downstream Prevent unnecessary stress in the system. With a four-position valve, these two valve shutoff positions are only 90 degrees or a quarter turn apart. Ball valve is mainly constructed of valve body, seat, ball, valve stem, handle (or other driving device). In a typical residential system, the issue is more philosophical than a real issue. Ball Valves. Thus the liquid remains in contact with the upstream side, or it simply vents away downstream, depending on which direction the valve is installed. Most types of Brass Ball Valves are easy to repair and operate. Posts: 389. A butterfly valve has a disc which is mounted on a rotating shaft. ANSI Class 150 & 300. Brass Ball valves are used extensively in industry because they are very versatile, supporting pressures up to 700 bars and temperatures up to 200C. Two types of DIB ball valves: DIB-1 Ball Valve: Double Piston Seat x Double Piston Seat.

Figure 4 illustrates the valves function and proper venting once the rail car is disconnected. (DN20) VG1000 Series Ball desired spring-return direction. Flow direction of conventional ball valves: Bidirectional. After WKM DynaSeal 370D4 Ball Valves are assembled and tested, the valves are left in the full DynaSeal 370D4 Ball Valves may be installed in most positions with flow from either direction. 2. Clamp one end of the valve firmly in a vise but not so tightly that you deform or crack the valve. Installation / Operating & Maintenance Instructions For H Series Needle, O.S.& Y., Hi-Pro Ball Valves & Flange Manifolds. 2. The ball may be free-floating or trunnion mounted. Install the valve with the flow arrow in the direction of flow. Clockwise rotation of the valve shaft closes the ball in the valve. Leakage: At high differential pressure, butterfly valves are prone to leakage. Item # 867990. On 1/2" valves, port A is the limited Cv port, unless specified otherwise. Do brass ball valves have to be oriented with the flow of Model # 22461LFCA Store SKU # 1001012670. To assist with installation Philmac ball valves can work in any direction and at any angle. Floating ball valve has double seal without direction, fixed type has single seal with direction. Either way is OK. To order, select a valve ordering number from the Swagelok Ball Valves, General Purpose and Special Application60 Series catalog, MS01146, and insert DV for downstream Prevent unnecessary stress in the system. With a four-position valve, these two valve shutoff positions are only 90 degrees or a quarter turn apart. Ball valve is mainly constructed of valve body, seat, ball, valve stem, handle (or other driving device). In a typical residential system, the issue is more philosophical than a real issue. Ball Valves. Thus the liquid remains in contact with the upstream side, or it simply vents away downstream, depending on which direction the valve is installed. Most types of Brass Ball Valves are easy to repair and operate. Posts: 389. A butterfly valve has a disc which is mounted on a rotating shaft. ANSI Class 150 & 300. Brass Ball valves are used extensively in industry because they are very versatile, supporting pressures up to 700 bars and temperatures up to 200C. Two types of DIB ball valves: DIB-1 Ball Valve: Double Piston Seat x Double Piston Seat.

As a rule of thumb, the flow direction of ball valves, no matter it is designed to floating type or trunnion mounted, shall be bidirectional. OMB Valves group. Fax: 262-432-2701. a. Not compression or shark-type, just plain old solder. Ball valves are not directional, but plumbing and engineering convention leads one to set up the valve handle to point in the direction of flow whenever possible. How to install the mini motorized ball valve? Electric actuated ball valve installation suggestions. Plumbing Installation suggestions: 1) For Maxmam weater protection,the valve should be mounted in a horizontal pipe run with the actuator above the ball valve. Valves can have the flow pass through in either direction. DynaSeal 370D4 Ball Valve Installation, Operation and Maintenance Manual. Model # M8934. The valve end to end is 4-1/2. Insert unthreaded pipe into the socket ends and bond with primer and cement to create a permanent, leak-tight connection. This action aligns the hole in the ball with the flow direction of the medium inside the duct, allowing it to pass freely through the ball valve. In the conventional design, two identical round To close, rotate handle (8) in clockwise direction until stop is felt up to a maximum torque of 6 Nm. Debris allowed to remain in the pipeline (such as weld spatters, welding rods, bricks, tools, etc.) If threads have been BUT, the way these shrk-bite connectors work is that you can only push the connector on in Temperature. Installing a 3/4" compression ball valve on a water distribution line. I'm trying to find out the correct flow direction through a ball valve-type shut off valve. The ball rotates with the valve stem to achieve the opening and closing action. In a typical residential system, the issue is more philosophical than a real issue. Use a wrench for both the valve and the pipe while tightening. 3 Way Ball Valve. If a valve must be installed in a certain direction, Publish Time: 09/26 2021 Author: Site Editor Visit: 318. Ball valves use a stainless steel ball to control water flow. Shop AMERICAN VALVE. When flow stops, the system back pressure pushes the ball against the seat stopping the flow. Ensure key length provides and maintains full engagement . Relieve the system pressure before performing any maintenance. Temperature and media compatibility should be verified prior to installation to assure the valve is able to The discs open under the flow pressure with direction from inlet port to outlet port. Valves are not intended to be a means of aligning improperly fitted pipe. Replace valve gate by removing the top body (bonnet) and stem. This feature can be provided in one direction or in both directions. Install top of body and refit into line. THIS WILL AFFECT THE VALVE WARRANTY.! Variety. (1) The valve must have a maximum service pressure rating for temperatures that equal or exceed the maximum service temperature. ball valve for installation. Tri Clover Compatible Ball Valves; Tri Clover Compatible Butterfly Valves; Tri Clover Compatible Sample Valves; Tri Clover Compatible Valve Replacement Seat Sets; Tri Clover Compatible Diaphragm Valves; 3A Compatible Weld-In Butterfly Valves; Tri Clover Compatible Ferrules. Everbilt 1-1/2 in. It's the quarter turn type for 1/2 inch copper, straight through, no drain cap. PEX Barb Ball Valve is a low cost solution to control water flow. This method is for installation and maintenance of wafer type butterfly valve or lug style butterfly valve with a cast iron body construction, SS stem and disc and either EPDM, BUNA-N or Viton liners. The ball valve take 1 1/2 inch of pipe in each side and the ball valve in 3 3/4 inches long, so math tells me that if I remove 3/4" of copper pipe, the ball valve should fit perfectly. DISASSEMBLY & CLEANING PROCEDURE: Caution: Ball valve can trap fluids in the ball cavity when closed. 4. If you are installing your swing check valve on a vertical pipeline, make sure the flow arrow is pointing up. ISO 14001 & ISO 9001 Registered Member: British Fluid Power Association Close the drain and place a towel in the bottom of the sink to prevent lost parts. Hayward's ball check valves have a true-union body design to simplify installation and maintenance. An example of this is a tank car unloading valve for dry chlorine. 3. 5. Valves marked with flow direction 2. Lever operation is standard on most of our ball valves; however; Oval Handles, Locking Ovals, Wing Handles, Extended Stems or Insulated Stem If the valve is opened, the ball rotates to a point where the hole through the ball is in line with the valve body inlet and outlet. 3.1 MANUAL BALANCING VALVES 7 3.1.1 Examples: Comparison Between A Balanced And An Unbalanced System 8 3.1.2 Double Regulating Valves 11 3.1.3 Regulating 2-way Control Valve 12 3.1.4 Fixed Orifice Flow Measurement Devices 12 3.1.5 Fixed Orifice Double Regulating Valves 13 3.1.6 Variable Orifice Double Regulating Valves 13 Status. INSTALL STEM ADAPTOR The V-ball, V "notch" is an exclusive design that allows precise flow with the ability to modulate and control the flow with 30, 60, or 90 degree V "notches". Attach Swing Check Valve onto Pipeline. Gas Engineer. The Stem controls the direction of the ball. In the conventional design, two identical round seats are fixed or floating on the upstream and downstream side of the ball. Do NOT subject ball check valves to freezing conditions. The instructions say: Cut a 2 section of the pipe. Remove the body seal.

- Festo Air Regulator Distributor

- Paper Tablecloths With Plastic Backing

- Lights For Taking Photos Of Products

- Bella+canvas Heather Orchid

- Pleatco Advanced Ultra Filter

- Nike Boonie Bucket Hat Camo

- Hydraulic Pipe Crimping Machine For Sale

- Tropical Leaf Print Dress

- Dyson V8 Replacement Parts

- Clear Coat For Stainless Steel Appliances

- Continuous Light For Macro Photography

- Digital Loyalty Programs

- Kirkland's Canvas Art Print

- Railing Planters Plastic

- Black Outdoor House Lights

- Juice Beauty Sport Sunscreen

- Jabra Evolve2 65 Software

- Abercrombie Simone High Rise Ankle White

Ensure key length provides and m 関連記事

- 30 inch range hood insert ductless

-

how to become a shein ambassador

キャンプでのご飯の炊き方、普通は兵式飯盒や丸型飯盒を使った「飯盒炊爨」ですが、せ …