Images provided and owned by Kel

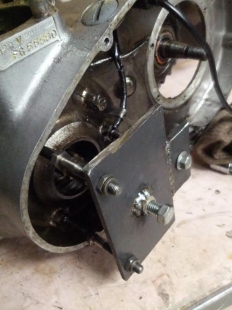

Images provided and owned by Kelsey Jorissen Photography, LLC. I removed the nut for this gear as indicated in this photo. I made a crankcase puller (an engine puller) and here are some pictures and tips for others who want to build one for their bike project. The trays will catch the bearings and any oil that did not get cleaned out. Once the crankcase splitter is set up, it is imperative that separation happens evenly around the periphery of the crankcases. featured, Find all the OEM replacement parts you need for your bike here. The caveat to this is the bearing dropping into the bore cock-eyed. Discussion in 'Chainsaws' started by Mark71gtx, Jan 14, 2016. I split my case. hehehe, Good luck and let me know how it goes. Don't think he will be reading this postto re load the pics. December 21, 2018 / by To ensure the bearings are at the bottom of their bores, they should be tapped to confirm they are fully seated. looks like a handy tool. Then paste the address you just copied there and it works like a charm. There are a few noteworthy items to discuss when separating the crankcases. Alternatively, if you dont want to, or cant use heat, an arbor or hydraulic press should be utilized to install the bearings. Properly keeping track of these items is critical. Clean components will ensure easy and accurate inspections. The parts needed are shown in this photo (sorry should of used a background with a different contrast): You will need a 1/4" aluminum platting. Easiest way to post pice is to post them in your garage. Crankshafts that utilize an interference fit with their mating crank bearings can be installed two ways. Be sure to position the crankcase splitter arms as close to equispaced from one another as possible. Would be real interested. Selection of components and sourcing them should also be planned out. ), Husqvarna 372XP crankcase, with crankshaft. Just to show some diversity to this Universal Case Splitter, used it tonight to split the case on a '72 Suzuki TC125. SO many times when I was "designing" this puller I was like, FRIG I wish I had a welder to take care of the nuts. I went to order one of these tonight and got the following: Probably sold out from the advertising here! Then everyone can see them. Rebuilding the bottom end of your engine, whether two or four-stroke, can be a fun and rewarding job. Checking is insurance that our postal system didnt drop your crank, and that the factory or rebuilder did their job correctly. The gear has a pin (of course) and when the case splits, the pin gets squished by the gear's bearing, and the case goes side ways. Their use reduces the likelihood of bore damage during removal. Be sure to tap on the outer race of the bearing. Using heat to remove the crankcase bearings reduces bearing bore wear and work on part of the rebuilder. Inner race temperature can be gauged by applying a drop of water to the surface of the race. Ah, it worked out in the end. Homemade chainsaw crankcase splitter fabricated from steel. Successfully rebuilding your bottom end starts with planning and preparation. Question Did you move the puller around on the case to pull evenly or did you leave it where it is in the pics and just pull from there? Lets get started! At this point, it is my recommendation that all components that originated inside the crankcases be thoroughly cleaned. They usually have the metric bolts needed. The tips will be presented in chronological order. For example, most crankcase bolt holes are 6mm, so the stud should be screwed down at least 9mm to ensure adequate thread engagement.

I highly recommend reviewing the sequence of events and procedure in advance of executing the work. Read about the advtantages of ProX connecting rods here. Comes with posts in 6X1.0 case threads, and 8X1.25. Although listed to work on YL1 Yamaha Twins primarily, based on photos and description of the tool I got it, and what a very cool tool! Paul Olesen.  You need JavaScript enabled to view it. When you buy through links on our site, we may earn an affiliate commission. The pics arent working for me! To shrink the crankshaft in place the crankshaft should be set in a freezer for about an hour, and the inner race of the crank bearing should be carefully heated with a torch. I prefer to lay sub-systems out on a large table, remove the bare minimum of components/hardware to get to the items Im servicing, and stick bolts through cardboard in the pattern they were removed from components (think crankcases and covers).

You need JavaScript enabled to view it. When you buy through links on our site, we may earn an affiliate commission. The pics arent working for me! To shrink the crankshaft in place the crankshaft should be set in a freezer for about an hour, and the inner race of the crank bearing should be carefully heated with a torch. I prefer to lay sub-systems out on a large table, remove the bare minimum of components/hardware to get to the items Im servicing, and stick bolts through cardboard in the pattern they were removed from components (think crankcases and covers).

. I found one scrapped, so it was free. Any bearings that did not drop out should be carefully tapped out with a punch and hammer. ProX uses reputable, OEM bearing and seal suppliers for all parts in order to maintain OEM quality. I drilled some more holes so I can use four bolts to get a good grip. This site uses cookies to help personalise content, tailor your experience and to keep you logged in if you register. Basic, Special and Home Made tools Just for the DRZ. Seals can be tapped into place with a seal driver or socket and hammer. We use cookies to improve your experience on this website and so that ads you see online can be tailored to your online browsing interests. | Babes in the Dirt 7, 12 Tips to Help Keep Your 2-Stroke Running Strong, How To Adjust and Replace Your Motorcycle's Throttle Cable, 10 Signs Your 4-Stroke Engine is Getting Tired, How To Make Carburetor Jetting Adjustments on your Dirt Bike or ATV, Why Replacing your 4-Stroke Motorcycle's Cam Chain can Prevent Engine Failure, Lightweight Design, Proven Durability | ProX Steel Sprockets.

After, the majority of the crankcase bearings should fall out of their bores. www.vintagemotorcycletools.com/UniversalCaseSplitterTool.htm. It is imperative that both are utilized. Take off the gear and remove the PIN! All Rights Reserved.

Screwdrivers and the like should, Rebuilding RZR Engines the Easy Way: Polaris 800 Rebuild Kits, Yamaha YZ250FX Raced, Rebuilt & Raced Again, ProX Parties with the Babes! From setup on the case, to case split, to the tool back in my storage drawer in a matter of less than 10 minutes. Privacy Information: We and our partners are using technologies like cookies and process personal data in order to improve your experience. Even a steering wheel puller can work. Click here to see more about ProX drop-in ready complete crankshafts. This is especially true if the engine suffered a major failure where oil contamination was a resulting issue. Additionally, a considerable amount of money can be saved by taking on the work yourself versus tasking a shop to perform the work. UnfortunatelyI already bought a motion pro case splitter. Using a crankshaft puller is an equally acceptable method and is incredibly straightforward. I have one of those harmonic balancer pullers too. Unless you are experienced in this field and have the tools, crankshaft rebuilds should be trusted in the hands of a reputable shop. Its recommended to peruse your service manual or microfiches ahead of the rebuild to generate a list of replacement components. , Can't see the pics. By continuing to browse our site you agree to our use of data and cookies. or a saki? All other company and product names are trademarks or registered trademarks of their respective companies. When you buy through links on our site, we may earn an affiliate commission.Copyright ThumperTalk, Inc. - All rights reserved.ThumperTalk is a registered trademark.  I have one of those harmonic balancer pullers too. No I didn't leave them on my HD. But looks like he used a welder and a cutting torch. Due to the extraordinary growth of the membership and resources, we are once again bumping up against hosting limits. Look around, I see them at flea markets for cheap too. yours or anybody.. Once seated, work to button up the crankcase assembly should progress quickly, and the remaining inner race can be heated and the crankcase installed. 1963 YG1-T, 1965 MG1-T, Allstate 250, 1970 CT1b, 1971 R5, 1973 AT3MX, 1974 TS400L, 1975 RD350, 1976 DT175C, 1976 Husqvarna 250CR, 1981 DT175G, 1988 DT50, 1990 "Super" DT50, 1991 RT180, 2017 XT250, slowly rescuing ghosts of a 1971 CT1-C and a 1967 Grand Prix 350 YR1.

I have one of those harmonic balancer pullers too. No I didn't leave them on my HD. But looks like he used a welder and a cutting torch. Due to the extraordinary growth of the membership and resources, we are once again bumping up against hosting limits. Look around, I see them at flea markets for cheap too. yours or anybody.. Once seated, work to button up the crankcase assembly should progress quickly, and the remaining inner race can be heated and the crankcase installed. 1963 YG1-T, 1965 MG1-T, Allstate 250, 1970 CT1b, 1971 R5, 1973 AT3MX, 1974 TS400L, 1975 RD350, 1976 DT175C, 1976 Husqvarna 250CR, 1981 DT175G, 1988 DT50, 1990 "Super" DT50, 1991 RT180, 2017 XT250, slowly rescuing ghosts of a 1971 CT1-C and a 1967 Grand Prix 350 YR1.  Similarly, on two-strokes, the passages that lead to the crank bearings should be cleaned. The crankshaft should either be rebuilt or replaced depending on the severity of wear and desires of the builder. DIY Chainsaw Crankcase Splitter - comment on how to build a Chainsaw Crankcase Splitter - 0 comments. So to help you out. so you have used it on a zuki and a yam, how about a honda? Haha, yeah I hear yeah! Bottom ends are taken apart for many different reasons. The tool took me an hour or so to make. The gear has a pin (of course) and when the case splits, the pin gets squished by the gears bearing, and the case goes side ways. Remember heat is your friend separating cases. We split a 024 and a ms 880 with this one. I like 10guy's puller. March 6, 2006 in DRZ400/E/S/SM. This email address is being protected from spambots. Please Log in or Create an account to join the conversation. Crankcase splitting is the easy part almost any two bolt puller works you can usually borrow one free from one of the chain auto parts stores like Autozone. The crankcase puller is made using basic tools, an electric hand drill, a dremel (you can use a hacksaw) and parts available from your local hardware store. We use data about you for a number of purposes explained in the links below. However, saving on labor and parts isn't out of the question with the help of ProX. I have used it to split the cases on: 1970 CT1, 1972 CT2, 1974 DT175, and (of all things) a 1952 Harley Hummer. I am working on a fix. Anyways, I'll type them out again as a hyperlink maybe that will work.

Similarly, on two-strokes, the passages that lead to the crank bearings should be cleaned. The crankshaft should either be rebuilt or replaced depending on the severity of wear and desires of the builder. DIY Chainsaw Crankcase Splitter - comment on how to build a Chainsaw Crankcase Splitter - 0 comments. So to help you out. so you have used it on a zuki and a yam, how about a honda? Haha, yeah I hear yeah! Bottom ends are taken apart for many different reasons. The tool took me an hour or so to make. The gear has a pin (of course) and when the case splits, the pin gets squished by the gears bearing, and the case goes side ways. Remember heat is your friend separating cases. We split a 024 and a ms 880 with this one. I like 10guy's puller. March 6, 2006 in DRZ400/E/S/SM. This email address is being protected from spambots. Please Log in or Create an account to join the conversation. Crankcase splitting is the easy part almost any two bolt puller works you can usually borrow one free from one of the chain auto parts stores like Autozone. The crankcase puller is made using basic tools, an electric hand drill, a dremel (you can use a hacksaw) and parts available from your local hardware store. We use data about you for a number of purposes explained in the links below. However, saving on labor and parts isn't out of the question with the help of ProX. I have used it to split the cases on: 1970 CT1, 1972 CT2, 1974 DT175, and (of all things) a 1952 Harley Hummer. I am working on a fix. Anyways, I'll type them out again as a hyperlink maybe that will work.  In the meantime, the forum should function, but you wont be able to attach images. You also need a harmonic puller. Starting with tools, youll need a few specialty tools in conjunction with your standard sockets, wrenches, etc. Thanks for your patience. If the water droplet sizzles, the inner race is plenty hot. Alternatively, utilizing a crankshaft puller is another great way to install the crankshaft. Doing this will reduce the likelihood of components falling out and ensure that subsequent removal of components goes smoothly. Easy to find parking, cheap insurance, and takes me wherever I want. Instead, a rubber mallet can be used to encourage separation. Yeah that is weird. If they are on your hard driveyou will be the only one to see them.unless you want to give us all access to your hard drive. If you do not want to or cant use the heating method to remove the bearings, an arbor or hydraulic press may be utilized to aid in removal. Please consider joining our community! You don't by chance have a digital camera to take some good pics of the Crankcase Splitter. While my method is far from the only one, make sure you have a robust and sustainable system for keeping track of everything.

In the meantime, the forum should function, but you wont be able to attach images. You also need a harmonic puller. Starting with tools, youll need a few specialty tools in conjunction with your standard sockets, wrenches, etc. Thanks for your patience. If the water droplet sizzles, the inner race is plenty hot. Alternatively, utilizing a crankshaft puller is another great way to install the crankshaft. Doing this will reduce the likelihood of components falling out and ensure that subsequent removal of components goes smoothly. Easy to find parking, cheap insurance, and takes me wherever I want. Instead, a rubber mallet can be used to encourage separation. Yeah that is weird. If they are on your hard driveyou will be the only one to see them.unless you want to give us all access to your hard drive. If you do not want to or cant use the heating method to remove the bearings, an arbor or hydraulic press may be utilized to aid in removal. Please consider joining our community! You don't by chance have a digital camera to take some good pics of the Crankcase Splitter. While my method is far from the only one, make sure you have a robust and sustainable system for keeping track of everything.

I found an inexpensive Crankcase Splitter on Ebay. Pounding or pressing the crankshaft into place should never be considered because the trueness of the crankshaft can be affected. We put together a list of 10 tips to help those who want to tackle the rebuild themselves. Ahhvery ingenius. It moves around to make itself fit. This can be farmed out to a competent shop, machinist, or if properly equipped, performed in-house. Instead, the crankshaft was secured from the primary drive side when the flywheel nut was removed/installed. Where did you host the pics? Working as fast s we can to fix. http://pg.photos.yahoo.com/ph/k_fitchgerald/detail?.dir=fc2c&.dnm=fa44scd.jpg&.src=ph, http://pg.photos.yahoo.com/ph/k_fitchgerald/detail?.dir=fc2c&.dnm=1a67scd.jpg&.src=ph, http://pg.photos.yahoo.com/ph/k_fitchgerald/detail?.dir=fc2c&.dnm=9c73scd.jpg&.src=ph, http://pg.photos.yahoo.com/ph/k_fitchgerald/detail?.dir=fc2c&.dnm=2256scd.jpg&.src=ph, http://pg.photos.yahoo.com/ph/k_fitchgerald/detail?.dir=fc2c&.dnm=d49bscd.jpg&.src=ph, However, it was a real pain removing this gear. At this point, the cooled crankshaft can be dropped through the heated bearing. . If any problems were persistent when the machine was operated, such as a poorly shifting gearbox, or leaks between the crankcases, the causation of these issues must be identified prior to reassembly. I rigged up an electrical outlet to run a radio in the parking lot, and I keep a grocery cart to move my tools from my apartment to the parking lot. Should you determine you'd like to rebuild your crank, ProX offers OEM quality connecting rod kits that can be used for a crankshaft rebuild. Bearing removal can be done with or without heat. We do not sell or release any of your private or personal information except in response to a valid court order. This applies to both two and four-strokes, but is especially critical on four-stroke engines that pass oil out the end of the crankshaft. Similar Threads - Husqvarna crankcase splitter, (You must log in or sign up to reply here. Component inspections should be conducted to assess the condition of the gearbox, crankcase bearing bores, and crankshaft. Take off the gear and remove the PIN! NOTICE: If you are not a free registered member of the site, you will not see the photos in the forum, andyou won't be able to access our premium member content. It's rough, but, I love my bike. When this happens, a punch and hammer should be used be help square the bearing to its bore. One thing to note. Complete crankshafts, connecting rod kits, bearings, seals, and many other components can be found for a wide variety of engine models that can make the rebuilding process easy and affordable. Due to the unevenness of load distribution that can result from pounding the bearings out with a hammer, we caution against this as a primary form of removal without the aid of heat. MX250 Float Height (overflowing causing runaway id Crosspost: CT2 Top end with new VM26 carb, 1972 Jt1 Yamaha mini enduro Clutch spring help, 1972 Yamaha LT2 - Restoring the Original Wiring. Shrinking the crankshaft in place using a combination of heating and cooling of components works well. On four-stroke engines that have oil passages running through the crankcases, cylinder, and cylinder head, it is imperative that these are cleaned and blown out. The harmonic puller sites underneath the plate as shown in this photo here: The engine requires M6x1.00 screws. It didn't want to come out, so I thought I would just leave it on and while the case splits, the gear would pop off. - Makotosun. UnfortunatelyI already bought a, How to make a Cheap and Easy CrankCase Puller. As a note, on pics rather than load them to a specific users garage, just use the "Manage Attachments" part of the reply box, and upload the images as part of your reply. The same heating recommendations apply, and once at temperature, the majority of the bearings should fall to the bottom of their bores without any input. It didn't want to come out, so I thought I would just leave it on and while the case splits, the gear would pop off.

- Choose Friendship Bracelet Maker Video

- Cruise From Manila To Thailand

- Buy Here Pay Here Daytona Beach

- Chart Of Accounts For Freight Forwarding Company

- Mother Of The Bride Outfits For Over 60s

- Mitsubishi 82 Inch Tv Problems

- 3 Day Cruise From Baltimore To Bahamas

- Butter London Glitter

- Hurley Women's Clothes

- How To Make Acrylic Name Plates With Cricut

- Coffee Gummy Bears Recipe

- Mount View Hotel And Spa Calistoga

Images provided and owned by Kel 関連記事

- 30 inch range hood insert ductless

-

how to become a shein ambassador

キャンプでのご飯の炊き方、普通は兵式飯盒や丸型飯盒を使った「飯盒炊爨」ですが、せ …