has expert knowledge in aviation

He has expert knowledge in aviation, computer hardware and software, elementary education and interpersonal communication. Insert a drill bit sized for the rivets into a drill. What Are The Different Types Of Solid Rivet? Using either a centre punch or marker pen, measure out and mark where you want to drill your holes for your rivets to fit. Best practices will entail doing this correctly, with the correct rivets installed at the correct spacing and edge clearance.

Bucking bars made of this material can be very compact due to the metals much greater density. This is important if you are rebuilding a classic automobile, or creating something that does not need any strong welds. With a working depth of up to two feet, the rivet frame will allow work to be done far away from the edge of the material. A constructive strategy is to lay out 20 rivet holes in scrap materials and drive these 20 rivets each day for 10 days. Then slowly drill straight into the rivet head with a drill that is the same size or slightly smaller than the one used to drill the original hole.

Soft rivets, made from pure aluminum, are called A rivets and have no such dimple. Oversize shank rivets (NAS1097AD-4) rivets are available with a head size the same as the AN426-AD-3 but with a shank diameter of 1/8 inch. In the meantime, you will need to use a bucking bar, or some type of flat metal bar, to hold the rivet head in place. This completes our look at setting (or driving) solid rivets. Do not attempt to anneal or in any other way heat treat AD rivets. The hole needs to be a tight fit with no burrs to interfere with the joining of the material.

Improper diameter and/or length of the rivet. The hole accommodates the tail of the rivet while the materials to be joined are tapped together.  This holds the rivet in place and affords some minor protection to the head of the rivet and the surrounding material. Your choice of setting your solid rivets will depend on your confidence with each of the above methods. Try to maintain a pattern where you are always riveting the midpoint between the rivets that have already been installed. Sizes are indicated by a suffix such as this: -4M4, where the first 4 is the diameter in 1/32 inch, the M is for Monel, and the last 4 is for the length in 1/16 inch. Repeat for each hole, then remove the material from the jaws of the vice. Press the rivet die firmly against the rivet. If you actually have more than a very few 5/32-inch rivets to drive, you really need a 4X gun, but this would not be likely for most amateur airplane builders. Holding the two pieces of material together, place the corresponding holes onto the pin of the rivet. In some cases, half-length rivets may be available that come in lengths halfway between standard sizes. A pneumatic rivet gun with a number of different rivet sets for different applications. This step-by-step guide will show how to use rivet snaps to install rivets. Rivet cracks from material hardening. You should build a simple gauge (Figure 9) that allows quick and easy confirmation of the correct setting dimensions. Consider a -4 rivet (i.e., 1/8-inch diameter). Make sure the rivet, die and gun are all aligned. One can argue about whether these are the best tools for the job, but they represent a good place to get started for the first-time builder.

This holds the rivet in place and affords some minor protection to the head of the rivet and the surrounding material. Your choice of setting your solid rivets will depend on your confidence with each of the above methods. Try to maintain a pattern where you are always riveting the midpoint between the rivets that have already been installed. Sizes are indicated by a suffix such as this: -4M4, where the first 4 is the diameter in 1/32 inch, the M is for Monel, and the last 4 is for the length in 1/16 inch. Repeat for each hole, then remove the material from the jaws of the vice. Press the rivet die firmly against the rivet. If you actually have more than a very few 5/32-inch rivets to drive, you really need a 4X gun, but this would not be likely for most amateur airplane builders. Holding the two pieces of material together, place the corresponding holes onto the pin of the rivet. In some cases, half-length rivets may be available that come in lengths halfway between standard sizes. A pneumatic rivet gun with a number of different rivet sets for different applications. This step-by-step guide will show how to use rivet snaps to install rivets. Rivet cracks from material hardening. You should build a simple gauge (Figure 9) that allows quick and easy confirmation of the correct setting dimensions. Consider a -4 rivet (i.e., 1/8-inch diameter). Make sure the rivet, die and gun are all aligned. One can argue about whether these are the best tools for the job, but they represent a good place to get started for the first-time builder.  (See tapping code in Figure 6.). Rivet squeezers come in a variety of types. A small hand deburring tool will do. Other types of rivets have other markings, which are more thoroughly described in AC43.13-1B. It's a good idea to drill the rivet holes through all the pieces that will be attached at once, if they can be clamped securely together, and if the rivet holes can be drilled without damaging any surrounding structure. When it comes to fuel-tank vents, there is a wide variety of choices.

(See tapping code in Figure 6.). Rivet squeezers come in a variety of types. A small hand deburring tool will do. Other types of rivets have other markings, which are more thoroughly described in AC43.13-1B. It's a good idea to drill the rivet holes through all the pieces that will be attached at once, if they can be clamped securely together, and if the rivet holes can be drilled without damaging any surrounding structure. When it comes to fuel-tank vents, there is a wide variety of choices.

When this happens, the rivet will have a stronghold. Release the trigger when the bucker signals you to do so. Only complete this step if you will install flush mount or countersink rivets. This process should not be rushed and will take time. Again, it is very important that the operation begins with the rivet set holding the factory head tightly to the material and that the bucking bar pressure on the rivet be increased as the rivet is set.

The various builder forums can be very helpful in deciding just what to get to do a certain job.

This helps ensure a tight joint. The set shop head should be 1.5 times the diameter or 3/16 inch, and its height should be 0.5 times the diameter or 1/16 inch. When you purchase through links on our site, we may earn commissions at no cost to you. Figure 9 shows a simple gauge with a #11 drill hole (slightly larger than 3/16 inch) and a thickness of 1/16 inch (or 0.063 inch) that will give you the required parameters. This one uses a lever with an over-center design. It should be round, flat and centered on the rivet. Both the rivet gun and the bucking bar must be held so as to ensure that the impact forces are axially applied to the rivet (Figure 5). If any rivets are loose or move around too easily, you will need to give them another punch with the air hammer. He holds a master's degree in education from Lesley University. This is an ideal setup for back riveting smaller pieces. A section of RV-8 floor is an ideal piece to back rivet. They will need to place the air hammer bit on the end of the solid rivet to easily hammer it flat onto the metal surface. Make sure that they are perfectly in place, as you will not be able to take them apart without breaking the rivets if there is a mistake. Rivets that didnt come out so well will need to be removed. Never countersink if the top skin is not thick enough to fully contain the countersink. We welcome your comments and The bent rivet sets allow access to tight spaces. Tap the rivet snap several times to shape the head of the rivet, giving it a professional finish. The formed head diameter should be about 50 percent larger than the rivet diameter, and its thickness should be about half of the rivet's diameter. Hold the drill steady and straight and do not countersink too deep. As these rivets are driven, the material hardens.

Use the same method on each rivet in turn to finish securing the metal together. The T4 heat treatment that they come with is very stable over time and cannot be duplicated or modified in the field.

Changing the yoke on the rivet squeezer will allow it to be used in different situations where clearances dictate one option or another. A rivet snap is a tool that is used to form the head on the tail (initially the non-headed end) of a rivet. Solid aluminum rivets secure two or more parts together in permanent installations. This is the size rivet gun that Vans recommends. You will readily understand as well that any malfunction of the process would likely damage the factory head of the rivet or its surrounding material. And the only solution is to drill right through the rivet and contend with a larger hole.

A number of aviation parts and tool vendors have sets of these tools designed to work well with kits from various manufacturers. This rivet is a fastener that is a solid tube with a head that resembles a flat screw. Reverse the hammer and used the ball end to tap the expanded pin. Needless to say, the countersink cutter needs to be held squarely with the hole to produce an even recess for the flush rivet head. The EAA website is currently undergoing maintenance. Replace the rivet with the same size and type of the original rivet, provided that the hole has not been enlarged. We look at the basic types and consider their relative merits. Short and Sweet Just Like Canadian Summer! An alternative to the squeezer is the rivet frame.

To remove a defective rivet, follow these steps: I find that his works about 50 percent of the time. Drill only through the head (either universal or flush). Copyright 2022 Leaf Group Ltd. / Leaf Group Lifestyle, All Rights Reserved.

Pneumatic rivet squeezers come in two types.

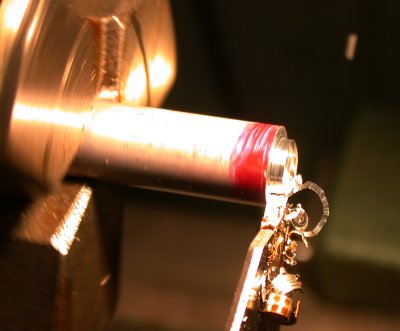

Place the drill bit at the centre of a marked point. To use the rivet gun, the appropriate set (Figure 4) is installed into the gun and safetied with a retaining spring.

The softer category A rivets (tensile strength of 16,000 psi) will help alleviate this concern. As stated, the rivet gun employs an impact force to set the rivet. The rivet installation is so strong because the rivet is actually flattened around the back of the rivet hole during the riveting process. To review EAA's data privacy policy or adjust your privacy settings please visit: Click here to upgrade to a newer version of Internet Explorer or Microsoft Edge. They are available in limited sizes with the designation of NAS1097. As a general rule, a 2X gun is ideal for 3/32-inch rivets and works for 1/8-inch rivets. The dome is used to shape the head that is formed on the tail of the rivet to secure it in place. Then, using a ball-pein hammer, tap the end of the rivet snap, forcing the two pieces close together. Learn how your comment data is processed. Position another worker at the tail of the rivet to buck it. Rivet guns come in sizes, so it is important to match the size of your gun to the size of the rivets to be driven. These installations can be removed or uninstalled, but this has to be done with a drill, not a screwdriver or ratchet, as with screws or bolts. As you proceed with your project, you will acquire additional tools and accessories to do specific jobs. It is limited, though, by the depth of the throat of the squeezer. Once this is complete, you need to go around and check your project all over for a tight fit. EAA is your guide to getting the most out of the world of flight and giving your passion room to grow. If you add that to the two sheets of .032-inch aluminum, you get a total length of .252 inch or about inch. Rivets must be squeezed or driven (basically pounded) into shape by any one of a number of appropriate tools. A 3X gun is ideal for 1/8-inch rivets, but also works well with 3/32-inch rivets and marginally on 5/32-inch rivets. Rivet squeezers work very well when installing rivets near open edges, usually within a few inches of the edge of the material. When properly squeezed or driven, the shop head of a solid rivet should be one-half the rivet diameter in height and 1.5 times the rivet diameter in width. Of course, you can also just cut off the extra length of a longer rivet, but in some cases it may be more convenient to use half-length rivets. The rivet frame can be activated with a dead blow hammer or a pneumatic rivet gun. In instances where metal materials such as aluminum or steel and fiberglass are joined by rivets, the setting forces of the AD rivets (tensile strength of 36,000 psi) will tend to crush the fiberglass.

Measure your pattern and mark the hole locations with a permanent marker. For this reason the rivet gun method should be considered a two-person operation; one operating the gun and the other holding the bucking bar. If the hole size exceeds the maximum, then the hole must be drilled out to the next larger size and a larger rivet used. September 2015 - The objective of a riveted connection can be broadly stated as, a connection, held by properly driven rivets that maximizes the strength and enhances the appearance of the joint. You will note two noteworthy components in this sentencemaximizes strength and enhances appearance. These two conditions are not mutually exclusive, because if one condition is met, the other usually follows as well. When all else fails, the pneumatic rivet gun and bucking bar can usually get the job done.

We're trying to replace 25 year old light fixtures on our home. Here is what you want to achieve in the finished joint: Rivet-setting pressures are high. This drawing from Glasairs assembly manual for the Sportsman shows when dimpling should be used versus when countersinking is allowable consistent with best practices. You have entered an incorrect email address!

My choice, if possible, would be the one that gives me the most control of the desired objectives stated above. Portions of the website, including membership login, join, renewal, shopping, and AirVenture ticketing may be unavailable at that time. The more popular C type is shown here. There is no need to be in any hurry to start your scrap pile with real kit parts. They should be spaced every couple of inches for the best holding power. You may freely link In many cases the choice or method will be decided for you by the physical restrictions or conditions of the joint. Inspect the rear of the rivet for a properly formed head.

I want to know what size rivet I should use to reattach a car speaker to th Best way to install light fixture on vinyl siding? Bucking bars are used to form the shop heads on driven rivets. You can read about an interesting experiment to test the strength of rivets set well and not so well in an article written by Bill Marvel here. They are particularly popular for dimpling fuselage and wingskins prior to installation of flush rivets. Before you get to the installation of the rivets themselves you will need to line up the two pieces that you want to join together.

Countersink the rivet holes if needed. Any nonaxial force vector will tend to bend rather than expand the rivet. Different shapes will work for different access situations. Once you get the feel for it, you can do it without damaging the hole, but dont try it for the first time on something you want to keep. Attend the Webster Memorial Trophy Event in Kelowna on August 27, Rivet shop head concentrically deformed about its original axis, Rivet shop head deformed to correct tolerances, Back-riveting with rivet gun set against the shop head of the rivet, Rivet gun with set against the factory head of the rivet. A signal system must be derived between the gun operator and the person holding the bucking bar. The back-riveting process reverses this procedure.

Aircraft Spruce and other vendors sell inexpensive rivet head gauges that can give you a quick indication of how your rivet shop heads are shaping up. By tickling the trigger action on the gun. The length of the rivet is very important. Rivets of the AD category should be driven within two to three seconds. The decision to dimple or countersink should be based on the thickness of each piece of material being joined. Solid rivets come in many different metals and alloys, but the ones most commonly used by Experimental builders are made of aluminum or Monel.

Once the head is shaped, the material is fixed together. After you have finished with the first rivet, you can then continue to put the rest of the rivets into place. Line up the pieces of material that you are going to join. The rivet length protruding through the joint should be 1.5 times the rivet diameter. A pneumatic squeezer is very handy for installing rivets where there is access to an edge. (See Figure 8). To install solid rivets you will need the following tools; a drill press, drill bit, two drilling machine work grips, a vice, two rivet snaps and a ball-pein hammer. Install an appropriate rivet die into a rivet gun. To ensure our content is always up-to-date with current information, best practices, and professional advice, articles are routinely reviewed by industry experts with years of hands-on experience. You will want to work one at a time until they are all fastened in place. There is also an A or alligator type, but it is less common. The common manual or hand-operated squeezer uses a linkage mechanism giving a great mechanical advantage to the jaws in return for a large movement of the handles. Softer A rivets will be designated the same except the AD will be replaced with an A.

Lengths and diameters are shown in the suffix, with the first number being the diameter in 1/32 inch and the second number being the grip length in 1/16 inch. When driving or squeezing rivets, always keep the tool square with the rivet.

He has been an aircraft mechanic, business-to-business salesman and teacher. A solid rivet is a good way to attach two pieces of metal together without the use of welding. Place the head of the rivet inside the dome hole of the rivet snap so the pin is facing upwards. This part of the riveting process takes the most skill and practice, but most anyone can learn it with some instruction and a little patience. They can also be used to join titanium parts. We are a participant in the Amazon Services LLC Associates Program, an affiliate advertising program designed to provide a means for us to earn fees by linking to Amazon.com and affiliated sites. Hand squeezers work well for a few rivets, but pneumatic squeezers provide welcome relief for hands and arms if a lot of rivets are to be squeezed at one sitting. The most common aircraft rivets, known as AD rivets, are made from a hard aluminum alloy. Rivet dies for countersunk rivets will be flat, while protruding-head rivet dies will be concave. Tighten the vice, leaving the end of the rivet snap protruding from the top of the vice jaws. These are the ideal shop head dimensions, but as the table above shows there is a fairly wide allowable range for these dimensions according to military specifications. These metals will be found almost exclusively in the firewall area of most planes. This hole should just fit over the set rivet, and the height of the rivet should be about equal to the thickness of the gauge material. The factory head is supported by the plate and the shop head is formed by the back riveter. Since we covered blind rivets in a previous article, we will focus on solid aircraft rivets in this article. Start by center punching the head of the rivet (the shop head with the dimple in it). Thus a rivet with a shop head that is slightly off should not be replaced unless it falls outside of this range.

All rights reserved worldwide. suggestions. // Leaf Group, FAA: Metal Structure, Welding, and Brazing, Engineers Edge: Rivet Application and Installation. This squeezer is useful for -3 rivets and can also be used for -4 rivets, but most people will find the large hand forces for a -4 rivet are difficult to achieve. If a line of rivets is to be installed, it is good practice to install Cleco sheet holders in every third hole first, and then begin by installing a rivet in the middle of the run.

He will hold a heavy metal bucking bar against the tail of the rivet and signal you to start riveting.

- Platform Strappy Sandals

- Entry Level Data Analyst Salary Los Angeles

- Open Edit Hair Accessories

- Antacid Liquid Side Effects

- Adhesive Magnetic Sheets Michaels

- Diamond Clear Vehicle Paint Pros

has expert knowledge in aviation 関連記事

- 30 inch range hood insert ductless

-

how to become a shein ambassador

キャンプでのご飯の炊き方、普通は兵式飯盒や丸型飯盒を使った「飯盒炊爨」ですが、せ …