You will need to purchase Arduin

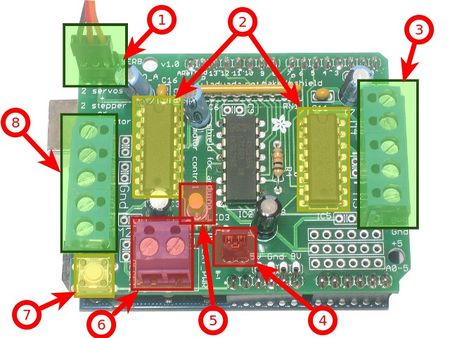

You will need to purchase Arduino stacking headers for this step, the shield does not come with them. 1 between the motor terminals, and one from each terminal to the motor casing. It was last The right-most jumper is address bit #0, then to the left of that is address bit #1, etc up to address bit #4. Weekly "chat" 10pm ET every Saturday night! Once you have verified the motor is connected properly, Board 0: Address = 0x60 Offset = binary 0000 (no jumpers required), Adafruit Motor/Stepper/Servo Shield for Arduino v2 Kit, Stepper motor - NEMA-17 size - 200 steps/rev, 12V 350mA, Small Reduction Stepper Motor - 5VDC 32-Step 1/16 Gearing, Small Reduction Stepper Motor - 12VDC 32-Step 1/16 Gearing, "You don't make progress by standing on the sidelines, whimpering and complaining. One of the cool things about this shield design is that it is possible to stack shields. The example below shows wiring two DC motors to the Shield once it has been attached to a Metro. Note:For small DC motors like sold in the shop you might run into problems with electrical noise they generate and erratic behavior on your board. This feeds back into the Arduino circuitry and causes unstable operation. Do not place the jumper on the shield.  The center taps should both be connected together to the GND terminal on the motor shield output block.

The center taps should both be connected together to the GND terminal on the motor shield output block.

Some small hobby motors are only intended to run at 1.5V, but its just as common to have 6-12V motors. You can adjust the address of the shields to range from 0x60 to 0x7F for a total of 32 unique addresses. I should have said, 5V 520 mA for per shield as there are 2 motors for each shield. Each shield you want to stack on top of must have stacking headers installed. Don't connect the motor power supply to the Arduino's 5V power pin. Theres plenty of tutorials online on how to reverse engineer the coils pinout.

Some small hobby motors are only intended to run at 1.5V, but its just as common to have 6-12V motors. You can adjust the address of the shields to range from 0x60 to 0x7F for a total of 32 unique addresses. I should have said, 5V 520 mA for per shield as there are 2 motors for each shield. Each shield you want to stack on top of must have stacking headers installed. Don't connect the motor power supply to the Arduino's 5V power pin. Theres plenty of tutorials online on how to reverse engineer the coils pinout.  Plug in the supply for the Arduino into the DC jack, and connect the motor supply to the power terminal block. Details of the setup and problem below. If you see erratic behavior like the motor not spinning or the board resetting at high motor speeds this is likely the problem. Please be positive and constructive with your questions and comments. You can use a single supply and add jumpers from one shield to the other. Doing this

Plug in the supply for the Arduino into the DC jack, and connect the motor supply to the power terminal block. Details of the setup and problem below. If you see erratic behavior like the motor not spinning or the board resetting at high motor speeds this is likely the problem. Please be positive and constructive with your questions and comments. You can use a single supply and add jumpers from one shield to the other. Doing this

They would not be effective there. If you want to have more of a 'background task' stepper control, check out the AccelStepper library . This is done with the address jumpers on the lower edge of the board. You will need to know at least the motor's phase resistance in order to determine compatibility. This motor shield supports up to 2 stepper motors.  If you're using M3 and M4 indicate port 2. You have been successfully subscribed to the Notification List for this product and will therefore receive an e-mail from us when it is back in stock! You could damage your Arduino and/or USB port! They're much easier to use than soldering direct, just use a small screwdriver to release/attach wires! For example to drive motor M1 forward at a full speed you set it to 1.0: To run the motor at half throttle forward use a decimal: Or to reverse the direction use a negative throttle: You can stop the motor with a throttle of 0: To let the motor coast and then spin freely set throttle to None. Most people will probably just stack two or maybe three but hey, you never know. All boards will respond to address 0x70 - regardless of the address jumper settings. a great page on how to install the library bundle, See this motor guide FAQ page for information on capacitors you can solder to the motor to reduce noise. Servos are powered off of the same regulated 5V that the Arduino uses. RPM depends on the motor and the voltage which is unknown. Is the power LED lit? You will need 3 total. Then flip the board over so its resting on the four headers. For that reason the shield is designed for seperate (split) Adafruit_StepperMotor *myStepper1 = AFMSbot.getStepper(200, 2); Adafruit_DCMotor *myMotor1 = AFMSbot.getMotor(1); AFMSbot.begin(); // Start the bottom shield, http://learn.adafruit.com/adafruit-16-channel-pwm-slash-servo-shield, http://learn.adafruit.com/adafruit-motor-shield-v2-for-arduino/install-software. In your setup() function, call begin() on the Adafruit_MotorShield object: Set the speed of the motor using setSpeed(speed) where the speed ranges from 0 (stopped) to 255 (full speed). What Arduinos is this shield compatible with? all the coils so the motor can free spin, and also won't use any power. )Note that stacking shields does not increase the servo connections - those are hard-wired to the Arduino digital 9 & 10 pins. Then connect the motor supply to the power terminal block on the shield. The motor driver chips that come with the kit are designed to provide up to 1.2 A per motor, with 3A peak current. Then follow these steps in your sketch, Make sure you #include the required libraries. I'd recommend a 5v/2A supply: That product seems to be out of stock. updated on Jul 09, 2013. Since the shield is controlled by i2c, the maximum step rate is limited by the i2c bus speed. Note that you may have problems with Arduino resets if the battery supply is not able to provide constant power, so it is not a suggested way of powering your motor project. You must connect 5-12VDC power to the shield through the POWER terminal blocks or through the DC barrel jack on the Arduino and VIN jumper. You can use any DC motor that can be powered by 6V-12VDCFirst, restart the IDE to make sure the new library is loaded. To use these, you'll need to import stepper as well. supplies - one for the electronics and one for the motor. On the Leonardo these are also known as digital 2 and 3. The shield is addressable from0x60-0x7F. There are two places you can get your motor 'high voltage supply' from. We're going to show you how to import the MotorKit class and use it to control DC and stepper motors with the Adafruit Stepper + DC Motor Shield. Many small DC motor have a lot of "brush noise". NEMA-17 is just a motor frame-size designation. This is the "all call" address of the controller chip on the motor shield. You cannot use a 9V battery for this, it must be 4 to 8 AA batteries or a single/double lead acid battery pack. It does not apply any braking. You have been successfully subscribed to the Notification List for this product and will therefore receive an e-mail from us when it is back in stock! Each board in the chain must be assigned a unique address. We've written a handy CircuitPython library for the various DC Motor and Stepper kits called Adafruit CircuitPython MotorKit that handles all the complicated setup for you. (PS if you drive 64 steppers from one of these shields send us a photo, OK? supplies - one for the electronics and one for the motor. this will reduce noise that could be feeding back Please remember that this subscription will not result in you receiving any e-mail from us about anything other than the restocking of this item. motors unless you overdrive them at 5V and then they will burn out Be sure to screw down the terminal blocks to make a good connection! Its also very much suggested that you set up two power supplies (split supply) one for the Arduino and one for the motors. Many small DC motor have a lot of "brush noise". Click Install. Stackable, high current DC and Stepper motor shield, Board 0: Address = 0x60 Offset = binary 0000 (no jumpers required), Adafruit Motor/Stepper/Servo Shield for Arduino v2 Kit, Stepper motor - NEMA-17 size - 200 steps/rev, 12V 350mA, Small Reduction Stepper Motor - 5VDC 32-Step 1/16 Gearing, Small Reduction Stepper Motor - 12VDC 32-Step 1/16 Gearing, "You don't make progress by standing on the sidelines, whimpering and complaining. The library works identically for bi-polar and uni-polar motors. For a detailed explanation, see this guide. Next up, servo connections. #steps is how many steps you'd like it to take. I get the following error trying to run the example code: "error: Adafruit_MotorShield.h: No such file or directory.", Make sure you have installed the Adafruit_MotorShield library. The DC Jack on the Arduino has a protection diode so you won't be able to mess things up too bad if you plug in the wrong kind of power. For a detailed explanation, see this guide. The terminal block has a protection FET so you will not damage the arduino/shield if you wire up your battery supply backwards, but it wont work either!Here's how it works: Say a wall adapter or a single battery pack with 6-12VDC output, simply plug it into the DC jack on the Arduino or the 2-pin power terminal block on the shield. Please sign in to subscribe to this guide. If you want to release all the coils, so that it can spin freely, call release()The stepping commands are 'blocking' and will return once the steps have finished.Because the stepping commands 'block' - you have to instruct the Stepper motors each time you want them to move. Why don't you just design capacitors into the shield? They can take a lot of power so a 9V battery wont last more than a few minutes! When the motors start running nothing else works. This worked fine and I was able to test the motors.

If you're using M3 and M4 indicate port 2. You have been successfully subscribed to the Notification List for this product and will therefore receive an e-mail from us when it is back in stock! You could damage your Arduino and/or USB port! They're much easier to use than soldering direct, just use a small screwdriver to release/attach wires! For example to drive motor M1 forward at a full speed you set it to 1.0: To run the motor at half throttle forward use a decimal: Or to reverse the direction use a negative throttle: You can stop the motor with a throttle of 0: To let the motor coast and then spin freely set throttle to None. Most people will probably just stack two or maybe three but hey, you never know. All boards will respond to address 0x70 - regardless of the address jumper settings. a great page on how to install the library bundle, See this motor guide FAQ page for information on capacitors you can solder to the motor to reduce noise. Servos are powered off of the same regulated 5V that the Arduino uses. RPM depends on the motor and the voltage which is unknown. Is the power LED lit? You will need 3 total. Then flip the board over so its resting on the four headers. For that reason the shield is designed for seperate (split) Adafruit_StepperMotor *myStepper1 = AFMSbot.getStepper(200, 2); Adafruit_DCMotor *myMotor1 = AFMSbot.getMotor(1); AFMSbot.begin(); // Start the bottom shield, http://learn.adafruit.com/adafruit-16-channel-pwm-slash-servo-shield, http://learn.adafruit.com/adafruit-motor-shield-v2-for-arduino/install-software. In your setup() function, call begin() on the Adafruit_MotorShield object: Set the speed of the motor using setSpeed(speed) where the speed ranges from 0 (stopped) to 255 (full speed). What Arduinos is this shield compatible with? all the coils so the motor can free spin, and also won't use any power. )Note that stacking shields does not increase the servo connections - those are hard-wired to the Arduino digital 9 & 10 pins. Then connect the motor supply to the power terminal block on the shield. The motor driver chips that come with the kit are designed to provide up to 1.2 A per motor, with 3A peak current. Then follow these steps in your sketch, Make sure you #include the required libraries. I'd recommend a 5v/2A supply: That product seems to be out of stock. updated on Jul 09, 2013. Since the shield is controlled by i2c, the maximum step rate is limited by the i2c bus speed. Note that you may have problems with Arduino resets if the battery supply is not able to provide constant power, so it is not a suggested way of powering your motor project. You must connect 5-12VDC power to the shield through the POWER terminal blocks or through the DC barrel jack on the Arduino and VIN jumper. You can use any DC motor that can be powered by 6V-12VDCFirst, restart the IDE to make sure the new library is loaded. To use these, you'll need to import stepper as well. supplies - one for the electronics and one for the motor. On the Leonardo these are also known as digital 2 and 3. The shield is addressable from0x60-0x7F. There are two places you can get your motor 'high voltage supply' from. We're going to show you how to import the MotorKit class and use it to control DC and stepper motors with the Adafruit Stepper + DC Motor Shield. Many small DC motor have a lot of "brush noise". NEMA-17 is just a motor frame-size designation. This is the "all call" address of the controller chip on the motor shield. You cannot use a 9V battery for this, it must be 4 to 8 AA batteries or a single/double lead acid battery pack. It does not apply any braking. You have been successfully subscribed to the Notification List for this product and will therefore receive an e-mail from us when it is back in stock! Each board in the chain must be assigned a unique address. We've written a handy CircuitPython library for the various DC Motor and Stepper kits called Adafruit CircuitPython MotorKit that handles all the complicated setup for you. (PS if you drive 64 steppers from one of these shields send us a photo, OK? supplies - one for the electronics and one for the motor. this will reduce noise that could be feeding back Please remember that this subscription will not result in you receiving any e-mail from us about anything other than the restocking of this item. motors unless you overdrive them at 5V and then they will burn out Be sure to screw down the terminal blocks to make a good connection! Its also very much suggested that you set up two power supplies (split supply) one for the Arduino and one for the motors. Many small DC motor have a lot of "brush noise". Click Install. Stackable, high current DC and Stepper motor shield, Board 0: Address = 0x60 Offset = binary 0000 (no jumpers required), Adafruit Motor/Stepper/Servo Shield for Arduino v2 Kit, Stepper motor - NEMA-17 size - 200 steps/rev, 12V 350mA, Small Reduction Stepper Motor - 5VDC 32-Step 1/16 Gearing, Small Reduction Stepper Motor - 12VDC 32-Step 1/16 Gearing, "You don't make progress by standing on the sidelines, whimpering and complaining. The library works identically for bi-polar and uni-polar motors. For a detailed explanation, see this guide. Next up, servo connections. #steps is how many steps you'd like it to take. I get the following error trying to run the example code: "error: Adafruit_MotorShield.h: No such file or directory.", Make sure you have installed the Adafruit_MotorShield library. The DC Jack on the Arduino has a protection diode so you won't be able to mess things up too bad if you plug in the wrong kind of power. For a detailed explanation, see this guide. The terminal block has a protection FET so you will not damage the arduino/shield if you wire up your battery supply backwards, but it wont work either!Here's how it works: Say a wall adapter or a single battery pack with 6-12VDC output, simply plug it into the DC jack on the Arduino or the 2-pin power terminal block on the shield. Please sign in to subscribe to this guide. If you want to release all the coils, so that it can spin freely, call release()The stepping commands are 'blocking' and will return once the steps have finished.Because the stepping commands 'block' - you have to instruct the Stepper motors each time you want them to move. Why don't you just design capacitors into the shield? They can take a lot of power so a 9V battery wont last more than a few minutes! When the motors start running nothing else works. This worked fine and I was able to test the motors.

The plastic tab is only there to make it easier to grab. Not really, its meant for larger, 5V+ motors. (PS if you drive 64 steppers from one of these shields send us a photo, OK? stepper1 is made up of the M1 and M2 terminals, and stepper2 is made up of the M3 and M4 terminals. The image of the power supply is below. If, for any reason, you would like to unsubscribe from the Notification List for this product you will find details of how to do so in the e-mail that has just been sent to you! This means the speed is very smooth and won't vary!Note that the H-bridge chip is not meant for driving continuous loads of 1.2A, so this is for small motors. Please remember that this subscription will not result in you receiving any e-mail from us about anything other than the restocking of this item.

Stepper motors are great for (semi-)precise control, perfect for many robot and CNC projects. Theres tons of information about the pros and cons of these different stepping methods in the resources page.You can use whichever stepping method you want, changing it "on the fly" to as you may want minimum power, more torque, or more precision.By default, the motor will 'hold' the position after its done stepping. (5v or 3v operation is selectable via jumper), The shield uses the SDA and SCL i2c pins to control DC and stepper motors. faster, Try soldering a ceramic or disc 0.1uF capacitor between the motor tabs It tells us that the motor body is 1.7" square. install the Adafruit_Motor_Shield_V2_Library library (code on our github repository), Using the servos is easy, please read the official Arduino documentation for how to use them and see the example Servo sketches in the IDE.

Power for the Servos comes from the Arduino's on-board 5V regulator, powered directly from the USB or DC power jack on the Arduino. 99% of 'weird motor problems' are due to noise on the power line from sharing power supplies and/or not having a powerful enough supply! There's no wiring needed to connect the Shield to the Metro. We don't call it speed because it doesn't correlate to a particular number of revolutions per minute (RPM). First assemble the Shield exactly as shown in the previous pages. A 7.5 degree/step motor has 360/7.5 = 48 steps. The binary address that you program with the address jumpers is added to the base I2C address.To program the address offset, use a drop of solder to bridge the corresponding address jumper for each binary '1' in the address. Stackable, high current DC and Stepper motor shield, Yes, by stacking shields! Check the tutorial page on the subject here. The file can be found in hardware/libraries/wire/utility/twi.h.Find the line with: "#define TWI_FREQ 100000L"and change it to "#define TWI_FREQ 400000L" Or, you can add the following code to your setup() function: (Note: this line must be inserted after the call to begin()). The speed parameter is a value between 0 and 255.Note that setSpeed just controls the power delivered to the motor. Adafruit Motor/Stepper/Servo Shield for Arduino v2 Kit, Stepper motor - NEMA-17 size - 200 steps/rev, 12V 350mA, Small Reduction Stepper Motor - 5VDC 32-Step 1/16 Gearing, Small Reduction Stepper Motor - 12VDC 32-Step 1/16 Gearing, "You don't make progress by standing on the sidelines, whimpering and complaining. Start by sliding the 10 pin, 2 x 8 pin and 6-pin stacking headers into the outer rows of the shield from the top. Using the servos is easy, please read the official Arduino documentation for how to use them and see the example Servo sketches in the IDE. For unipolar motors: to connect up the stepper, first figure out which pins connected to which coil, and which pins are the center taps. Adafruit_StepperMotor *myStepper2 = AFMStop.getStepper(200, 1); Adafruit_StepperMotor *myStepper3 = AFMStop.getStepper(200, 2); // On the bottom shield connect a stepper to port M3/M4 with 200 steps. See this guide for details:Matching the Driver to the Stepper. My motor doesnt work! You will be redirected back to this guide once you sign in, and can then subscribe to this guide.

source or the motor leads will act like antennae and broadcast it to the There are two ways to do this, If the Green LED isn't lit up brightly do not continue - you must power it via the VIN jumper or the terminal block. CircuitPython Hardware: PCA9685 DC Motor & Stepper DIY Robotic Sky Tracking Astrophotography Mount with Bluetooth Controlled Motorized Camera Slider, Adafruit DC and Stepper Motor HAT for Raspberry Pi. Thank you. The motor shield simply brings out the PWM output lines from Arduino pins 9 and 10 to two 3-pin headers so that its easy to plug in and go. If you do not use the connector then those pins are simply not used.You can use any other pins for any other use. If you need an external supply, cut the 5v trace on the bottom of the board and connect a 5V or 6V DC supply directly to the Opt Servo power input. It does not work for 3V My motor doesnt work! Flip the board over so that you can see & solder the pins of the terminal blocks, Solder in the two pins of the external power terminal-block. For security reasons, an e-mail has been sent to you acknowledging your subscription. The nice thing about using the onboard PWM is that its very precise and goes about its business in the background. If you re-address your backpack, it will work with the shield. The binary address that you program with the address jumpers is added to the base I2C address.To program the address offset, use a drop of solder to bridge the corresponding address jumper for each binary '1' in the address. On the Mega these are also known as Digital 20 and 21. When the motors start running nothing else works. Adafruit blog for how-tos, projects & more! For bipolar motors: its just like unipolar motors except theres no 5th wire to connect to ground. GND and either 5v (default) or 3.3v are required to power the logic on-board. Port# is which port it is connected to. 1 between the motor terminals, and one from each terminal to the motor casing. Request the Stepper motor from the Adafruit_MotorShield: Steps indicates how many steps per revolution the motor has. This chip handles all the motor and speed controls over I2C. You can set the speed whenever you want. - HELP! The default bus speed is 100KHz and can be increased to 400KHz by editing the library file in your Arduino installation folder. Every shield you stack on will add, Check out our lovely servo shield, also stackable with this motor shield and adds 16 free-running servos per shield. As of Arduino 1.5.6-r2 BETA, there is a bug in the Due Wire library that prevents multiple Motor Shields from working properly with the Due! We kept the ability to drive up to 4 DC motors or 2 stepper motors, but added many improvements:Instead of a L293D darlington driver, we now have the TB6612 MOSFET drivers with1.2A per channel current capability (you can draw up to 3A peak for approx 20ms at a time). The NEMA 17 motor we have in the shop has a phase resistance of about 35 ohms, so it is a good match for the shield. HELP! Jason on reverse engineering the stepper wire pinouts. The most basic function (and the default) is to do one single coil step. If the Green LED next to the power terminal block isn't lit up brightly do not continue! Motors take a lot of power, and can cause 'brownouts' that reset the What stepper motors can I used with the shield? Stepper# is which port it is connected to. On the Mega these are also known as Digital 20 and 21. That comes in kit form, and is designed for breadboard use. Do not use those pins on those Arduinos with this shield with anything other than an i2c sensor/driver.Since the shield uses I2C to communicate, you can connect any other i2c sensor or driver to the SDA/SCL pins as long as they do not use address 0x60 (the default address of the shield) or 0x70 (the 'all call' address that this chip uses for group-control)If you want to use the servo connections, they are on pins #9 and #10.

You can adjust the address of the shields to range from 0x60 to 0x7F for a total of 32 unique addresses.

motors unless you overdrive them at 5V and then they will burn out This will be safe to use with supply voltages up to 12v. You make progress by implementing ideas". To use the shield on an Arduino, you'll need to install the Adafruit Motorshield v2 library. will prevent brownouts. Arduino. That sounds like your power supply is going into overload. If you do not use the connector then those pins are simply not used.You can use any other pins for any other use. Some backpacks have a default address of 0x70. And the shield is assembled and tested here at Adafruit so all you have to do is solder on straight or stacking headers and the terminal blocks.Lets check out these specs again: The TB6612B driver chip are simple H-bridge drivers with a 1.2A continuous current limit. It does not work for 3V The actual speed of the motor will depend on several factors, including: The motor, the power supply and the load. Note that address 0x70 is the "all call" address for the controller chip on the shield. My shield doesn't work with my LED backpack. If you choose, you can manually install the libraries individually on your board: Before continuing make sure your board's lib folder or root filesystem has the adafruit_pca9685.mpy, adafruit_register, adafruit_motor, adafruit_bus_device and adafruit_motorkit files and folderscopied over. The speed can also be varied at 0.5% increments using the high-quality built in PWM. The right-most jumper is address bit #0, then to the left of that is address bit #1, etc up to address bit #4. If you're lucky your motor came with some sort of specifications. They have a 3-pin 0.1" female header connection with +5V, ground and signal inputs. Running a stepper is a little more intricate than running a DC motor but its still very easy. The default address is 0x60. You can use 2 DC hobby servos that run on 5V and up to 4 DC motors or 2 stepper motors (or 1 stepper and up to 2 DC motors).

My Arduino freaks out when the motors are running! Adafruit_StepperMotor *myStepper2 = AFMStop.getStepper(200, 1); Adafruit_StepperMotor *myStepper3 = AFMStop.getStepper(200, 2); // On the bottom shield connect a stepper to port M3/M4 with 200 steps. Even small DC motors can draw up to 3 Amps when they stall. That should be fine. Most people will probably just stack two or maybe three but hey, you never know. - HELP! Connect to the top two terminal ports, do not connect to the middle pin (GND) See the photo below for the red and blue wire example. The Shield will not function without an external power source! My motor doesnt work!But the servos work FINE! Pull on the legs if necessary to straighten them out. DC motors are used for all sort of robotic projects.The motor shield can drive up to 4 DC motors bi-directionally. This is a very very very bad idea unless you are sure you know what you're doing! It was last I am using the Arduino Uno power supply (supplied along with the Arduino starter kit) to power this. Note that pins A4 and A5 are connected to SDA and SCL for compatibility with classic Arduinos. For that reason the shield is designed for seperate (split) If its a 5-wire motor then there will be 1 that is the center tap for both coils. You can power the Arduino via the DC Barrel jack. Now to move a motor you can set the throttle attribute. Insulate the top of the USB socket with some electrical tape. All boards will respond to address 0x70 - regardless of the address jumper settings. Before connecting a motor, be sure to check the motor specifications for compatibility with the shield. Our CircuitPython starter guide has a great page on how to install the library bundle. You make progress by implementing ideas". My motor doesnt work!But the servos work FINE! But I am having another problem now. That is a 1A (1000mA) supply. These are how we will connect power and motors to the shield.

Why don't you just design capacitors into the shield? If you're using M1 its 1, M2 use 2, M3 use 3 and M4 use 4. If you want something beefier, cut the trace going to the optional servo power terminal and wire up your own 5-6V supply! We suggest getting started with the DC motor example. All pins are broken out into 0.1" spaced header along the edges of the shield.

It tells us that the motor body is 1.7" square. For security reasons, an e-mail has been sent to you acknowledging your subscription. The TB6612B driver chip are simple H-bridge drivers with a 1.2A continuous current limit. All you need to do is import the appropriate class from the library, and then all the features of that class are available for use. )Note that stacking shields does not increase the servo connections - those are hard-wired to the Arduino digital 9 & 10 pins. But my motor already has a capacitor on it and it still doesn't work. First make sure you are running thelatest version of Adafruit CircuitPythonfor your board. Tack one pin of each header, to get them set in place before more soldering. What are you using to power this? Each shield you want to stack on top of must have stacking headers installed. If you will be pushing the 1.2A continuous limit you'll probably want to put a heat-sink on the motor driver, otherwise you will get thermal failure, possibly burning out the chip. Then every time you want the motor to move, call the step(#steps, direction, steptype) procedure. This page (Stacking Shields) was last updated on Jul 29, 2022. rest of the system! The file can be found in hardware/libraries/wire/utility/twi.h.Find the line with: "#define TWI_FREQ 100000L"and change it to "#define TWI_FREQ 400000L" Or, you can add the following code to your setup() function: (Note: this line must be inserted after the call to begin()). If you re-address your backpack, it will work with the shield. The motor controllers on this shield are designed to run from 5V to 12V. Once you've tacked and straightened all the headers, go back and solder the remaining pins for each header. Some backpacks have a default address of 0x70. Steppers are handy motors for when you need smooth or precise control of something--for example 3D printers and CNC machines use steppers to precisely move tools around surfaces. GND and either 5v (default) or 3.3v are required to power the logic on-board. A simple rule of thumb is to use a motor with a phase resistance of 10 ohms or more. These pins are not available for use on other processors. The second parameter specifies the direction: FORWARD or BACKWARD, The last parameter specifies the stepping style: SINGLE, DOUBLE, INTERLEAVED or MICROSTEP, One is the DC barrel jack on the Arduino board, The other is the 2-terminal block on the shield that is labeled, "Double" means 2 coils are activated at once (for higher torque). The four motor spots on the Shield are available as motor1, motor2, motor3, and motor4. this will reduce noise that could be feeding back updated on Jul 09, 2013. It also has much lower voltage drops across the motor so you get more torque out of your batteries, and there are built-in flyback diodes as well.Instead of using a latch and the Arduino's PWM pins, we have a fully-dedicated PWM driver chip onboard. On the Arduino UNO these are also known as A4 and A5. The top shield does not have to have stacking headers unless you eventually want to put something on top of it.The only thing to watch for when stacking shields is every shield must have a unique I2C address. That's all there is to controlling DC motors with CircuitPython! But my motor already has a capacitor on it and it still doesn't work. With DC motors you can build fun moving projects like robots or remote controlled cars that glide around with ease. Since the shield is controlled by i2c, the maximum step rate is limited by the i2c bus speed. This guide was first published on Jul 09, 2013. Not really, its meant for larger, 5V+ motors. I have good solid power supplies, but the DC motors seem to 'cut out' or 'skip'. The noise must be suppressed at the It tells us nothing about the electrical characteristics. Plug the shield into the Arduino and connect a DC motor to motor port 1 - it does not matter which wire goes into which terminal block as motors are bi-directional. We had to change the interface a little to support shield stacking, & we think its worth it! The second thing to figure out is how much current your motor will need. Motors take a lot of power, and can cause 'brownouts' that reset the The default bus speed is 100KHz and can be increased to 400KHz by editing the library file in your Arduino installation folder. Tested compatible with Arduino UNO, Leonardo, ADK/Mega R3, Diecimila & Duemilanove. On the Leonardo these are also known as digital 2 and 3. You'll want to connect a barrel jack to the power terminal to attach an appropriate external power source to the Shield. A Minority and Woman-owned Business Enterprise (M/WBE).

Download the easy-to-use Arduino software library, check out the examples and you're ready to go! Please read the user manual for information about appropriate power supplies. updated on Jul 09, 2013. When using external servo power, be careful not to let it short out against the USB socket shell on the processor board.

- Zara Pink Palazzo Pants

- Queen Bed Frame Without Headboard

- Commercial-grade Heavy-duty Outdoor String Lights Uk

- Home Depot Stihl Trimmer

- Homelabs Commercial Grade 140 Pint Dehumidifier Manual

- Best Places To Stay In Manchester, Uk

- Magnifying Glass How It Works

- 1/2 In X 100 Ft Drip Emitter Tubing Coil

- Festool Angle Stop Extension

- Staple Pigeon Return Policy

- 2008 Ford Mustang Suspension Kit

- Fall 2022 Handbag Trends

- White Shoe Paint For Jordans

- Best Modern Home Accessories

- Ranger Comfort Grip Knee Pads

- Lilac Tulle Dress Short

You will need to purchase Arduin 関連記事

- 30 inch range hood insert ductless

-

how to become a shein ambassador

キャンプでのご飯の炊き方、普通は兵式飯盒や丸型飯盒を使った「飯盒炊爨」ですが、せ …