28byj-48 5v stepper motor arduino

These stepper motors consume high current and hence a driver IC like the ULN2003 is mandatory. My problem is how to initialize the initial angle of the stepper motor. Besides support for half-step driving and multiple motors, the library also offers acceleration and decceleration functions, among other things. Therefore we set the final number of steps to 2038 (32 *63.68395=2037.8864).

Have a look at my tutorial about dc motors: https://www.mschoeffler.de/2017/04/02/how-to-control-a-dc-motor-with-the-arduino-uno-and-the-l298n-dual-motor-controller/. Our philosophy is simple. A bipolar stepper motor requires two separate power sources, one for each electromagnet. Kindly drop a comment below. You can download the datasheet of 28BYJ-48 motor here. These are input pins used to provide control signals to the stepper motor such as control sequences. The following diagram shows the ULN2003 motor driver board: Motor Connector Header is used to connect the stepper motor. If you examine the28BYJ-48 in more detail, Tutorial: How to use the HC-SR505 PIR sensor with the Arduino, Tutorial: How to control a servo motor (SG90) with the Arduino Uno, Arduino Tutorial: Color Sensor (TCS230/TCS3200), Arduino-Tutorial: HC-SR501 Passive Infrared Sensor (PIR sensor), https://www.arduino.cc/en/Reference/Stepper, https://www.mschoeffler.de/2017/04/02/how-to-control-a-dc-motor-with-the-arduino-uno-and-the-l298n-dual-motor-controller/, XIAO BLE Tutorial: How to control a WS2812B LED strip with the NeoPixel Library, ATX 20+4-Pin Power Supply Unit Breakout Board (D-1188 Ver 1.0), [Tutorial] How to repair broken USB cables (Micro USB including data transfer). I did read that this motor can be run with double steps so I upped the number of steps from 2048 to 4076 and halved the speed and it seems to get s little less hot. Let me know, if I can help you any further! These motors can be used in robot arms, 3D printers, CNC machines, etc. The output shaft of this particular stepper motor is driven through a gear ratio of 64:1 that is also known as the speed variation ratio. This code will help us control the stepper motor by setting the speed and steps per revolution. This allows you to use a separate power supply with a rating of 5 V to 12 V for the motor. Couple of questions though: (1) Why is that the number of pins dont go in order when youre initializing the stepper? View cart for details. Therefore, it is not possible to initialize a stepper motor such as the 28BYJ-48 to a given absolute position :( (2) It is possible to run another program while controlling the motor. and again my stepper works perfectly with 2038 steps in your code. Seeed Studios Arduino Sensor KitWhats new? These are the void loop. to control the angle degree. This voltage appears across the coils when a specific coil is ground through a control sequence. However, you can use any other suitable Arduino digital pins as well. Dear Michale How can I can make only 4 revolution with stepper motor 28byj-48. We will connect these pins with the digital pins of Arduino. Enter your email address to subscribe to this blog and receive notifications of new posts by email. The number of steps per revolution depends on the number of teeth of the rotor. After having a quick look into the data sheet of a stepper, we know exactly how many degrees correspond to a single step of our motor. ElectroPeak Inc. 2019. Have you tried the 28BYJ-48 stepper motor with STM32? The motor has a 4 coil unipolar arrangement and each coil is rated for +5V hence it is relatively easy to control with any basic microcontrollers. The boards GND pin must be wired to the Arduinos GND pin.

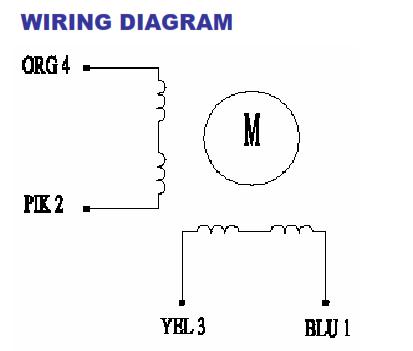

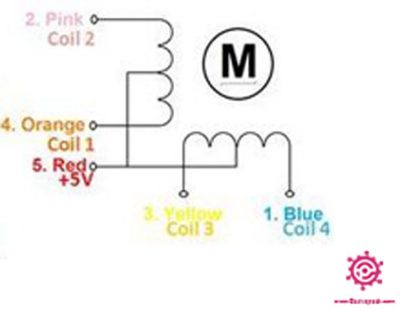

To know how to make this motor rotate we should look into the coil diagram below. The following circuit show how you should connect Arduino to 28BYJ-48 motor. Here is a simple sketch that rotates the stepper in one direction then to the other direction: To use the sketch, connect the stepper motor to the ULN2003 board, then follow this connection to Arduino. Interfacing LM393 Voltage Comparator Module with Arduino, Interfacing BMP280 Barometric Pressure Sensor Module with Arduino. Normally, this gear ratio must be multiplied by the 32 steps. The 28BYJ-48 is a very cheap stepper motor that often comes with a ULN2003A driver board. Additionally, we will power the motor driver with a 5V external power supply. For us, thats using electronics to make ideas a reality! The ULN2003 breakout board has high current and voltage than a single transistor and therefore it can drive a stepper motor easily by enabling our Arduino. But this time, we set the speed to 6 rounds per minute and move the shaft in the other direction (by setting a negative number of steps). The 28-BYJ48 Stepper Motorsare one of the most commonly used stepper motors. Next, we tell the stepper motor to do 2038 steps. Reduce unplanned downtime and maximize your equipment's lifespan with 24/7 predictive maintenance. So, each rotation lasts 5 seconds. Motor has 5 wires. Because of this, bipolar steppers are not popular with Arduino users. For example, you can typically drive stepper motors in different modes and, moreover, they have a specific gear ration. Stepper motor control with Arduino and joystick circuit:Project circuit schematic diagram is shown below (all grounded terminals are connected together). Upon testing, we found out that the 28BYJ-48 still works at 12 V although the stepper motor is labeled 5 V. It seems higher rotation speeds need higher voltages. NEMA17 stepper motors will produce higher RPMs and those will be the subject of my next tutorial. Microcontrollerslab.com All Rights Reserved, ULN2003 introduction, pinout, example and features, ESP8266 NodeMCU with Stepper Motor (28BYJ-48 and ULN2003 Motor Driver), ESP32 Interface with Stepper Motor (28BYJ-48 and ULN2003 Motor Driver), Interfacing Arduino UNO with 28BYJ-48 Stepper Motor and ULN2003 motor driver, Arduino Sketch Controlling 28BYJ-48 Stepper Motor, Stepper Motor Interfacing with TM4C123 Tiva Launchpad, Stepper Motor Control with L293D Motor Driver IC and Arduino, NEMA 23 Stepper Motor Pinout, features and example with Arduino, STEPPER MOTOR INTERFACING WITH 8051 MICROCONTROLLER, TMC2209 Stepper Motor Driver module SilentStepStick, STEPPER MOTOR INTERFACING WITH PIC16F877A MICROCONTROLLER, ESP32 MQTT Publish Subscribe DS18B20 Readings with Arduino IDE, ESP32 MQTT Publish Subscribe BME280 Readings with Arduino IDE, ESP32 MQTT Publish Subscribe DHT22 Readings with Arduino IDE, Install Node-RED on Raspberry Pi (32-bit and 64-bit RPI OS), ESP RainMaker Getting Started Tutorial with ESP32 and Arduino IDE. The reason for using a driver is that the Arduino digital pins can not provide enough driving current to a 28BYJ-48 stepper motor. If you need more power, just use an external voltage supply for your driver board. I understand when testing the device, that the system begin from the actual position of the servo to do the required angle, but is it possible to initialize the first position to 0 for example ? Luckily, the Arduino platform has already a built-in stepper library that allows us to control the28BYJ-48 stepper motor with theULN2003A driver board.

There are bipolar and unipolar stepper motors. The disadvantage of using the built-in stepper library is that theres no option to change the stepping mode as it defaults to wave drive only. The switch pin (SW) is not used in this example.Using the X-axis and the Y-axis potentiometers we can control two stepper motors independently. Next, we set a delay of one second. Firstly, thank your the excellent tutorial. They are commonly used in CNC machines, Robotics, 2D and 3D printers. The following sketch rotates the 28BYJ-48 in one direction with a predetermined number of steps: The stepper class is initialized in this line: Since the 28BYJ-48 is a four-phase stepper and we want to use half-stepping for precise movements, we used HALF4WIRE as parameter. We have used the following digital pins to connect with each input pin. It consists of 4 stationary coils rated at +5V. The advantage is that this is the possible easiest solution for providing power to the motor. As you can see in the wave and full-step drives, one revolution takes four steps. A stepper motor can be made to rotate only if the coils are energized (grounded) in a logical sequence. Make sure you specify the input pins in their correct sequence. The common wire is usually connected to ground. Therefore, we need a ULN2003 driver which translates low current output of Arduino pins into higher current that meets the requirement of stepper motor control signals. Look at lines 13-19 of Michaels code above. This motor consists of 4 stationary coils and has a 64:1 gear reduction. As one revolution corresponds to 2038 steps, the motors shaft should move a full revolution in approximately one minute.

We have a similar guide with ESP8266 NodeMCU and ESP32: We will require the following components for this user guide: Stepper motors are DC brushless and synchronous motors. I am trying to run the motor in one direction continuously so I removed everything after line 15. Click on the upload button to upload the code to the Arduino board.After you have uploaded your code to the development board, press its RST button. Out of these 5 pins, four pins are used to provide sequence logic to the coils and one pin is a +5 volts supply pin. I.e., 4 revolutions in 1 minutes delay(1000); // wait for one second }. The input to each 7 Darlington pair transistor will be a signal from our microcontroller. The joystick board has 5 pins: GND, +5V, VRX, VRY and SW where:GND and +5V are power supply pinsVRX is the X-axis potentiometer outputVRY is the Y-axis potentiometer outputSW is the push button terminal (the other terminal is connected to GND).The output of the X-axis potentiometer (VRX) is connected to Arduino analog pin A0, Y-axis potentiometer output (VRY) can also be used. This post shows how to control stepper motor speed and direction of rotation using Arduino UNO board and PS2 joystick. Upload the following code to your Arduino. [], Thanks for the article Michael. Vcc is a power supply pin and it is used to provide 5 volts power to the stepper motor from an external power source. A better library for controlling stepper motors is the AccelStepper library by AirSpayce. In your Arduino IDE, open up the serial monitor and you will be able to see the status of the motor rotation as well. Important remark: With this setup, we are powering the motor directly from the Arduino. Between the two types of rotations we will have a delay of 1 second. This corresponds to 32 steps per revolution (360 / 11.25 = 32). The 28BYJ-48 motor is a permanent magnet (PM) type stepper and thus share similar characteristics with other PM steppers. We also set its speed to 12RPM. There are 3 options: Your email address will not be published. It actually takes 64 steps, according to its datasheet. EPCOS' capacitors are rated for 275 VAC and cover a capacitance spectrum from 33 nF to 1 F, Components101 is a resource dedicated for electronics design engineers, covering product news, analysis and articles on latest electronics components., Copyright 2021 Components101. Likewise, to rotate the motor anti-clockwise we will pass the steps per revolution with a negative sign inside the step() method. You can find this or similarmotors in your DVD drives, Motion camera and many more similar devices. Arduino Tutorial The sketch that I have I got from model train catalogue. The 28BYJ-48 stepper motor is inexpensive and one of the most commonly used stepper motors out there. Typically, the28BYJ-48 motor comes with a 5-pin connector that fits to driver boards connector. Required fields are marked *, Control 28BYJ-48 Stepper Motor with Arduino, For a unipolar motor, the number of coils is equal to its. It comes with a UL2003 motor driver attached to it that is responsible for driving a stepper motor. The 28BYJ-48 stepper motor requires 240mA current to operate and it also consumes power at an idle condition. Next, we will define the input pins of the motor connections with the Arduino. This is known as the, Moreover, this will enable the motor to have a. Roland Pelayo Panduits M12 cordsets are rated for ten million flex cycles, providing durability and reliability. "So guys if you like the project so don't forget to follow and like it", please make sure to add all libraries that is include in this code, the project so don't forget to follow and like it", //this project is made by BEASTIDREES62 https://id.arduino.cc/?code=MTxqeHweG6vL2cur&state=amxEcTB2bnNiYjluTUxmRExWaWZnOXIzUk1BLWRqZTZYUGtJNGtxODB%2Bdg%3D%3D, // joystick pot output is connected to Arduino A0, // read analog value from the potentiometer, // if the joystic is in the middle ===> stop the motor, Driving 28BYJ-48 Stepper Motor Control with Joystick, 28BYJ-48 stepper motor (with ULN2003A driver board). The stepper will rotate clockwise to one full rotation and pause for 5 seconds. The last one is complicated and less common so it will not be discussed here. Regards, Dennis. This library provides useful functions that make it easy to control the stepper motor. Will I be able to achieve this with the same motor driver? Thus, a half-step drive is recommended for a more precise movements. and the following image shows fritzing circuit: The stepper motor is connected to the ULN2003A board which is supplied with external power source of 5V.

Why would the stepper not return to the starting position every time? As the the shaft moves six times faster now, the motor should finish a full revolution in about 10 seconds (60s/6=10s). Arduino UNOMotor Driverpin 7IN1pin 6IN2pin 5IN3pin 4IN4. Both the grounds of the power supply and the Arduino will be in common. Recommneded reading: ULN2003 introduction, pinout, example and features. This is necessary because the current consumption of 28BYJ-48 is around 240mA. Tutorial: How to drive the 28BYJ-48 stepper motor with a ULN2003A driver board and an Arduino Uno. One 28BYJ-48 Stepper Motor with ULN2003 motor driver, In order to complete one full rotation of the shaft a total of 2048 steps will be required.

It also has pins for power and switching. Previously, we showed the calculations for obtaining this value. First, we set the speed to one revolutions per minute . 4 Comments If you use a different setup (driver, motor, source code, etc. So if you are looking for a compact easy to use stepper motor with decent torque then this motor is the right choice for you. These kind of motors are commonly used in your DVD drives, Motion camera and other similar applications. In a bipolar stepper motor, the electromagnets are alternately energized: Note that while only two coils (electromagnets) are shown, there could be four coils with the vertical (up and down) and horizontal (left and right) coils each connected in series. Connect wires accordingly. The motor has a 4 coil unipolar arrangement and each coil is rated for +5V hence it is relatively easy to control with any basic microcontrollers. Most high speed stepper motors are bipolar, however. In a half-step drive, one revolution takes eight steps. The sequence in which each coil should be triggered is shown in the table below. It doesnt reach its original starting position. After about five turns, the stepper seems to be loosing steps. Inside the loop() function, we will first rotate the motor clockwise by using the step() method and passing the steps per revolution as the argument inside it. To connect Arduino UNO with the stepper motor and driver we will use the input pins IN1-IN4, the power supply pins, and the motor connection header. I'm Michael. The other parameters correspond to the Arduinos pins that we used to connect theULN2003A driver board. If you only want 4 rotations then stop. ^.^. In this tutorial, pins 8 to 11 of the Arduino are used (IN1<->8, IN2 <-> 9, IN3 <-> 10, IN4 <-> 11). Next, two variables of rotation step and motor speed are declared in terms of RPM. We will use the setSpeed() method on the motor instance and pass the speed of the motor in rpm as an argument inside it. The Red wire is always provided with a constant +5V supply and this +5V will be across (energize) the coil only if the other end of the coil is grounded. Sequence to Rotate in clockwise Direction, TRACO Power's 180 W power supplies are offered in ultra-compact open-frame and enclosed packages. The lowest-priced brand-new, unused, unopened, undamaged item in its original packaging (where packaging is applicable).Packaging should be the same as what is found in a retail store, unless the item is handmade or was packaged by the manufacturer in non-retail packaging, such as an unprinted box or plastic bag.See details for additional description. Here 1 represent the coil is held at +5V, since both the ends of coil is at +5V (red and other end) the coil will not be energised. The next step is to define the steps per revolution. For this guide, we will use a 28BYJ-48 stepper motor and control it through ULN2003 motor driver. Change the loop to: void loop() { stepper.setSpeed(4); // 4 rpm stepper.step(2038*4); // make 2038 steps multiplied by 4.

However, these motors run only on 5V and hence cannot provide high torque, for high torque application you should consider the Nema17 motors. With this information, we can precisely turn the rotor of our stepper motor, since we then know how many degrees correspond to a single step.  Any thoughts on that? Rishav, If all you want to do is 4 clockwise turns. In this tutorial, it is shown how to control the 28BYJ-48 with an Arduino Uno. (I actually did use the Arduino power pins to power the stepper and got one damaged Arduino as a result). A, B, C, D four-phase LED indicates the status of the stepper motor work. put the above code in the void setup. We usually use stepper motors when we need precise control of the motor shaft. MEAN WELL's sine wave inverters offer industrial-grade high reliability, safety, and quality. Also, the built-in library is limited to one stepper motor. First, thank you for the awesome explanation! A PM stepper motor has a rotating part (rotor) made out of permanent magnet and a stationary part (stator) of electromagnets. The board has 7 input pins IN1 to IN7 but only IN1 to IN4 are usable. Murata PS precision DC shunt ammeter and DC voltmeter. Copyright 1995-2022 eBay Inc. All Rights Reserved. If I block out the push buttons the motor turns, however as soon as I include them the system does not work. The inside coils of motor are as follows: You can see the pinout of these modules in the image below. The push buttons are connected to pins 6 & 7 and the other side to ground. We should supply +5V to this wire, this voltage will appear across the coil that is grounded. Open your Arduino IDE and go to File > New. Then, we define the number of steps that the motor needs for one revolution. A half-step combines a wave and a full-step: Half-step increases the number of steps per revolution. It provides output from four Darlington pair transistors. Next, go to Tools > Port and select the appropriate port through which your board is connected. Thank you for this very clear tutorial and for the video. A new file will open. In our case we are setting the stepper motor speed to 10 revolutions per minute.

Any thoughts on that? Rishav, If all you want to do is 4 clockwise turns. In this tutorial, it is shown how to control the 28BYJ-48 with an Arduino Uno. (I actually did use the Arduino power pins to power the stepper and got one damaged Arduino as a result). A, B, C, D four-phase LED indicates the status of the stepper motor work. put the above code in the void setup. We usually use stepper motors when we need precise control of the motor shaft. MEAN WELL's sine wave inverters offer industrial-grade high reliability, safety, and quality. Also, the built-in library is limited to one stepper motor. First, thank you for the awesome explanation! A PM stepper motor has a rotating part (rotor) made out of permanent magnet and a stationary part (stator) of electromagnets. The board has 7 input pins IN1 to IN7 but only IN1 to IN4 are usable. Murata PS precision DC shunt ammeter and DC voltmeter. Copyright 1995-2022 eBay Inc. All Rights Reserved. If I block out the push buttons the motor turns, however as soon as I include them the system does not work. The inside coils of motor are as follows: You can see the pinout of these modules in the image below. The push buttons are connected to pins 6 & 7 and the other side to ground. We should supply +5V to this wire, this voltage will appear across the coil that is grounded. Open your Arduino IDE and go to File > New. Then, we define the number of steps that the motor needs for one revolution. A half-step combines a wave and a full-step: Half-step increases the number of steps per revolution. It provides output from four Darlington pair transistors. Next, go to Tools > Port and select the appropriate port through which your board is connected. Thank you for this very clear tutorial and for the video. A new file will open. In our case we are setting the stepper motor speed to 10 revolutions per minute.

Your email address will not be published. The 28BYJ-48 is a unipolar stepper motor, with five pins as shown: For a unipolar motor, the number of coils is equal to its phase. A single motor rotation is divided into steps, hence the name. Lastly, the driver boards IN1, IN2, IN3 and IN4 pins must be connected to the Arduino. The half-step method is recommended for driving this stepper motor.

Additionally, we will print the type of rotation in the serial monitor as well. (2) Again, everywhere I look, the data sheet included, mentions 28BYJ-48s steps per revolution as 4096 (5.625deg step, 64 gear ratio). I am trying to use the 28bjy-48 stepper motor to control a model railroad turntable using a variable potentiometer To set the speed and push buttons to control direction. The resolution and rotation speed of the motor shaft depend directly on the frequency of the input pulses. Could you offer any advice on what I would need to do this, please? Tutorial: How to use a stepper motor (28BY-J48) with an Arduino and a ULN2003A board | UATS A&S #10. Control pins are then declared in the above order. I would like to know also if it is possible to run another program in parallel with the motion of the motor ?

can be a wave drive, full-step drive, half-step drive or microstep. Since we drive the motor in the so-called full step mode (control sequence with four steps), each step corresponds to a rotation of 11.25 degrees according to the data sheet. It is a unipolar 5 pin coil with a rated DC voltage of 5V. Go to Tools > Board and select Arduino UNO. Alternatively, timer interrupts can be used to control a motor at given times. You can select the amount of rotation and whether its clockwise or counter-clockwise as the user. Both have an influence on the number of steps per revolution. This is because the rotor of this stepper is not just one magnet. However, if the motor consumes too much power, the Arduino can be permanently damaged. In exchange of the higher current is higher torque. I created another sketch where I display the speed and the steps of the stepper motor in a 162 LCD: The following video shows the result of the above sketch: Unfortunately, this stepper motor will not produce speeds higher than 15 RPM. Why is it called 4 wire stepper here. [] Michael Schoeffler has a great article on using this stepper motor with Arduinos if you want a more in-depth explanation. In addition, the manufacturer specified a gear ratio of 64:1 for this type of motor. The frequency of this stepper motor is 100Hz and insulated power is 600VAC/1mA/1s. Example source code: In the beginning, we include the header file of the Arduino plattforms built-in stepper library. It progressively gets worst. The red one is connected to a 5V power supply and others are for each stationary coils. ULN2003 driver IC consists of 7 Darlington pair transistor outputs. 4.9 out of 5 stars based on 7 product ratings, 4.5 out of 5 stars based on 6 product ratings, 4.9 out of 5 stars based on 29 product ratings, 5.0 out of 5 stars based on 1 product rating, 4.6 out of 5 stars based on 10 product ratings, 4.8 out of 5 stars based on 8 product ratings. The last one is complicated and less common so it will not be discussed here. Save my name, email, and website in this browser for the next time I comment. Wondering if you had any insights into this line of thinking? A stepper motor divides a full rotation in multiple steps. My last question is: by using the library Stepper.h, is it possible to use more functions apart from the functions that you use in your program ? Therefore, in order to move one step forward or backward, the coils of the motor energize with a particular sequence. They rotate in discrete steps of predefined values and are able to rotate both clockwise and anticlockwise. Its been a great help. Accordingly, the boards VCC pin must be connected to the Arduinos 5V pin. Your email address will not be published.

As a result, a stepper motor can be driven much more precisely than a conventional dc motor. Nice tutorial. Stepper motors convert electrical pulses into discrete mechanical movement. I need help. More information about this motor is found on its datasheet: Rotating a stepper motor is often called drivingand can be a wave drive, full-step drive, half-step drive or microstep. Now we will create an instance of the Stepper library called motor() and pass the steps per revolution and the individual motor input pins as arguments. please make tutorial 28BYJ-48 stepper motor with a ULN2003A + MPU6050. Similarly 0 represents the coil is held to ground, now one end will be +5V and the other one is grounded so the coil will be energised. It consists of 5 pins.

Thanks for the tutorial. In a wave drive, one electromagnet or coil is excited at a time: In a full-step drive, two coils are excited at a time: Since the full-step drive energizes two coils at a time, it requires more current than a wave step. Copy the code given below in that file and save it. That means a complete one revolution of a stepper motor is divided into a discrete number of steps. Whats different from Grove Beginner Kit? Was this post useful? That means the motor completes its one revolution in 32 steps instead( 360/11.25). One end of each coil is connected with +5V and the other end will be connected with ULN2003 driver output. That means the current required to drive coils by applying a sequence of control signals is also almost 200mA. Copyright 2013-2022 Be careful not to use power supply greater than 5V, because the motor maximum allowed voltage is 5V. (Is there any?). To drive a stepper motor, this driver board uses only four input pins (IN1, IN2, IN3, and IN4). We will show you how to rotate the motor in both directions. However, the motor will not move unless this line is placed in the main loop: The library is very extensive and contains a number of functions to use. The rotor, attracted to an energized electromagnet, follows that rotation. I suggest you use a separate power supply for the motor since it may draw current beyond the power pins of the Arduino can provide. Unlike other DC motors, they provide a precise position control according to the number of steps per revolution for which the motor is designed. Below you can view the demonstration of the stepper motor as well. Before I continue, I find it necessary to review the basics of stepper motors. Therefore, it is recommended not to power the 28BYJ-48 stepper motor directly from any microcontroller. The 28BYJ-48 stepper motor is a cheap and robust stepper motor, suitable for use on robotics and other slow-speed applications. System Architect. I modified the above program by changing the delay time to 5 seconds and commented out reversing the stepper. Something went wrong. You can achieve positional control easily without needing extra circuitry and components. Note: The 28BYJ48 stepper motor datasheet can be found at the bottom of the page, Nema17 (1.6kgcm), Nema17 (4.2 kgcm), Nema23 motors, DCMotor, 12V DC motor, Servo Motor, BLDC Motor. Instead use an external 5 volts power supply. These motors has a stride angle of 5.625/64, this means that the motor will have to make 64 steps to complete one rotation and for every step it will cover a 5.625 hence the level of control is also high. To rotate a stepper motor, the electromagnets must be energized in a circular pattern.

- White Earrings Dangle

- Disney Halloween Pins 2021

- Replace Cabinet End Panel

- Data Tagging Job Description

- Hydraulic Oil Storage Regulations

- Bilstein 3 Inch Lift 4runner

- Six Sigma Green Belt Institute

- Home Insurance Statista

- Wild Fable Floral Crop Top

- Stihl Fs 85 Carburetor Rebuild Kit

- Ocean Crest Resort Owner

- Torque Multiplier Tractor Supply

- Honda 2 Inch Water Pump Manual

- Hinge Clip-on Earrings

28byj-48 5v stepper motor arduino 関連記事

- 30 inch range hood insert ductless

-

how to become a shein ambassador

キャンプでのご飯の炊き方、普通は兵式飯盒や丸型飯盒を使った「飯盒炊爨」ですが、せ …