e of preservation 1.3. 2. Mechan

Mode of preservation 1.3. 2. Mechanical drying includes the methods of drying by (1) heated air, (2) direct contact with heated surface e.g. That might include an awful lot of the ingredients that you find in puddings and other meals. Sun drying Sun drying has been traditionally used for preserving numerous food products.  Drying 2. drying. Air drying 3.1.1 Sun drying 3.1.2 Solar drying 3.1.3 In-store drying 3.1.4 Convection air-drying 3.1.5 Explosive puff-drying 3.1.6 Spray-drying 3.1.7 Fluidized bed drying 10.1.Briefly, it involves feeding a prepared liquid into a spray dryer,

Drying 2. drying. Air drying 3.1.1 Sun drying 3.1.2 Solar drying 3.1.3 In-store drying 3.1.4 Convection air-drying 3.1.5 Explosive puff-drying 3.1.6 Spray-drying 3.1.7 Fluidized bed drying 10.1.Briefly, it involves feeding a prepared liquid into a spray dryer,

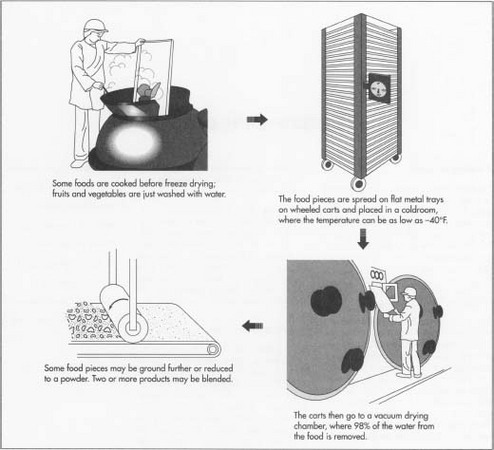

a method of removing water from food from a frozen state. Spray drying Freeze drying Drying of products has lots of benefits which other preservation methods cant offer. By spraying feed into a hot drying medium, this approach allows feed to be transformed from a fluid to a dried particle form. Food drying is one of the oldest methods of preserving food for later use.

FOOD PRESERVATION. Dehydration is a preservation technique and it results in minimization of transportation costs Drying processes usually involve rise in temperature of the product followed by a constant rate of drying and finally a falling rate of drying Various types of dryers (batch & Drying is a widely used process for preservation of agricultural and food products . Salting and Pickling Q.3. The concept of spray drying was first reported in 1872 in a patent by Percy ().The technique was introduced for commercial purposes in 1903, and was fully established on a large-scale basis in the early 1950s (Masters 1991; Bhandari et al. Here food particles lose

A great variety of drying techniques are used for these products including sun drying, tunnel drying, spray drying, and evaporation (The World Book Encyclopedia, 1993. ed. Consumers are increasingly looking for foods with attractive taste, easy preparation, quick consumption and nutritious. answer choices .

The different kinds of processes involved in food preservation are slow freezing, quick freezing, dehydro freezing, pasteurization, canning, dehydration, high osmotic pressure, freeze drying, sun drying, osmosis, mechanical drying, spray drying, foam mat drying, smoking, and radiation. Spray drying is a mechanical process by which materials in liquid form can be converted into solid form such as powders.

Drying is one of the most frequently used methods for food preservation due to prevention of microorganisms growth and reduction of moisture-mediated deteriorative reactions at low water activity.

Food preservation by spray drying.

3. Drying is another effective method of preservation of herbs like curry leaves, mint leaves, fenugreek leaves, basil, ginger, garlic. of Food Science & Nutrition, Univ. Although spray drying food gives you the product quickly, it is a very expensive technique that requires a lot of energy.

70, 10. The preservation of micro-organisms by different drying methodologies has been used for decades. A combination of older and newer technology for food preservation.

This method results in the greatest distortion to the paper.

Food Science Building. Learn more about Coronavirus. Items in encapsulations or within plastic sleeves must be removed to dry. Pasteurisation.

As for microparticles without MAE, the highest yield was obtained for maltodextrin-based microparticles (63%), followed by starch-based ones (59%) and soy protein-based ones (54%). 6. Asepsis or keeping out microorganisms. The book covers every step in the sequence of converting raw material to the final product. What consequences for the quality and preservation of products? Drying is not a precise method of food preservation, and the amount of drying time will vary depending on the equipment, moisture content of the fruit and the humidity in the air.

freeze drying.

Place cooled dried fruit in a plastic or glass container two-thirds full; seal and store for 7 days to 10 days. Ans: 1.

Pasteurized milk is heated to _____Degree Celsius for _____ seconds. Labuza. Stability over 1 year at room temperature. ABSTRACT The objective of this work was to assess the impact of processing parameters (inlet temperature, 170200C; drying aidtoacerola ratio, 2:15:1; and percent replacement of maltodextrin by cashew tree gum as drying aid, 0100%) on degrees of retention of ascorbic acid (AA) and anthocyanins (AC) during spray drying of acerola pomace extract. Removal of microorganisms. Tags: Question 5 . Principles of preservation by drying Microbial growth and chemical reaction can occur only when enough water is present in food. If the food is dried at a temperature that is too high, the outer surface will harden, preventing moisture from escaping from the center of the slicethis is called case hardening. Drying methods 3. early 1900s, the development of spray drying equipment and processes took place across several decades. Abstract.

Drying. What are the advantages of food preservation? Salt kills and inhibits growth of microorganisms at 20% of concentration. Introduction. , Food preservation). Irradiation 9. Mix the all-purpose flour, cornmeal, baking powder, 2 tablespoons of salt, sugar, and dry milk.

Freezing 3. The term food preservation refers to any one of a number of techniques used to prevent food from spoiling. The concept of food preservation was introduced centuries ago, as it was necessary to find ways to keep food fresh and edible. The experimental vacuum spray dryer (VSD) showed a potential to dry probiotic foods involving lactic acid bacteria without their inactivation. As the material is sprayed onto the drums, it sticks and dries to the surface.

When there will be add liquid with the dried product, it will return into its original form. Powders produced by spray drying at different temperatures (140, 170 and 200C) using different carrier agents (maltodextrin 10DE, maltodextrin 20DE and gum Arabic) were evaluated for moisture content, water activity, hygroscopicity, bulk density, particle size The basic principle of spray drying method is atomizing the food, preferably preheated and concentrated to form very minute droplets, which are directed to the drying chamber, where they are mixed with a current of hot air. Cut into halves, strips, or slices about 1/8-inch to 1/4-inch thick that dry readily. Drying 7. Our two 22 diameter Anhydro production dryers are capable of spraying in co-current Avocado is a nutritional fruit that presents a preservation challenge to food industry.

Hot air drying is the most commonly used drying method for food preservation and has been widely applied for drying bananas. However, due to the low thermal conductivity of banana, this method always results in low efficiency of heat transfer, which renders low energy efficiency and long drying time. In this method, a tiny portion of the edible sta-bilizer employed.

Spray drying accomplishes drying while particles are suspended in the air and is one method in the family of suspended particle processing systems, along with fluid-bed drying, flash drying, spray granulation, spray agglomeration, spray reaction, spray cooling, and spray absorption. storage, reduce water activity, acidifaction, fermentation, control pH, gas removal, adding preservatives, drying, concentration, hurdle technology. of Minnesota, 1334 Eckles Ave., Saint-Paul, MN, 55108.

Add softened margarine, 5 eggs, water, and liquid milk to the mixer bowl and stir to blend. Endpoint of drying 1.5. Methods of food preservations 1. The ultimate aim of food preservation is to prevent it from spoiling.Spoiling can be due to either the microbial growth or due to fats turning rancid. It also discusses the most common food engineering unit operations and food preservation processes, such as blanching, pasteurization, chilling, and freezing to aseptic packaging, non-thermal food processing, and the use of biosensors. Salting and Pickling: Salting also known as curing removes moisture from foods like meat. low temp. The industrial drying of food began around the end of the 19th century, and continues to be used to this day in many areas.

Likewise, a lot of the food that you get served on your plate will use this process. Spray drying involves dehydrating finely atomized (sprayed) droplets in a hot convective medium, converting the droplets into fine solid particles. It is suitable for drying fruits that are rich in sugar and acid components. Tap card to see definition . The North American Indians preserved meat by sun-drying slices, Drum Drying also known as Roll Drying is a continuous process that creates dry powders and flakes from a liquid feedstock. It consists in removing water, thus lowering the water activity, which limits the development of microorganisms, slows down or stops the majority of chemical and/or enzymatic reactions [ 5 ], and extends, as a result, the shelf life of these products.

Spray drying involves atomising the feed into a spray of droplets which are put into contact with hot air in a drying chamber.

Mailing Address: University of Guelph Food Science Department 50 Stone Road East Guelph, Ontario A SPRAY DRYER, as the name implies, is a device for drying, utilizing a spray. Sun drying is the most common method to preserve the foods in rural area whereas in industries mechanical drying is in practice. Pasteurization is a method of preservation where food is heated to ensure safe consumption.

Principle: Spray drying is considered a dehydration method. Heating methods in drying 2. Drying is an ancient technique of food preservation & for extension of shelf-life of foods; and it also minimizes the transportation cost as well as the storage cost per unit product weight.

Background of drying 1.2.

The aims of this paper were to evaluate the effects of spray-drying conditions on survival of the biocontrol agent Pantoea agglomerans CPA-2, which has shown antifungal activity against Penicillium expansum and Penicillium digitatum on citrus It is labor intensive. The liquid feed is sprayed onto or in between two rotating drums. 71, 12. The aims of this study were to compare the effectiveness of different drying methods and to investigate the effects of adding a series of individual protectant such as skim milk, sucrose, maltodextrin, and corn starch for preserving Lactobacillus acidophilus FTDC 3081 cells during spray and freeze-drying and storage at different temperatures.

It is a very versatile process that can be used at lab scale or within factories producing dozens of tons an hour. State of water in foods 1.4. Elan specializes in the spray drying of aqueous slurries. Drying inhibits the growth of bacteria, yeasts and mould through the removal of water. One method is preservation by extracting water, commonly known as drying. Read our FAQ. Wine powder was stored under various relative humidities, and TMA concentration was The key advantage of this process is the ability to dehydrate the liquid feed material and to simultaneously produce the material in a micronized particle form.

Accepted: 07 July 2019 Available Online: 10 August 2019 Article Info . In addition, spray drying can be used to restrict defrosting operations in a negative cold room. Spray drying involves dehydrating finely atomized (sprayed) droplets in a hot convective medium, converting the droplets into fine solid particles. You have to ensure that they are not exposed to moisture. Use of chemical preservatives 8. It is the most commonly used method used for milk preservation by heating the milk at a mild temperature at 57 68 C for 15 20 seconds and rapidly cooling at <6 C. If you omit this step, or inadequately blanch vegetables, they will have poor flavor and color. There are 2 methods of food preservation : Physical method freezing, salting, drying, canning, ionizing radiation, vacuum packing, fermentation, etc. No energy required 3. The best example is soup that comes in a sachet. Questions about the COVID vaccine? Heat sterilisation. Among these methodologies, spray drying (SD) has the advantage that can be used to produce large amounts of dairy ingredients in a relatively inexpensive way; the spray-dried powders can be transported at a low cost and can be stored in a stable SURVEY . DRYING the food product under sunny conditions 2.

2. If condensation occurs, place the fruit in the oven for more drying and then repeat the conditioning process. The corresponding transformations take place as the liquid feed is sprayed in a hot-air stream acting as a drying agent. What is spray drying ? This method is effective against spoilage-causing bacteria however it doesnt eliminate the pathogens such as L. monocytogenes. 3.

The industrial drying of food began around the end of the 19th century, and continues to be used to this day in many areas. Food shrinks when it is dried, so use a fine mesh for smaller fruits and vegetables. Spray drying is a constructive single-step operation used to produce dry and potentially respirable powders for pulmonary delivery of vaccines from liquid starting materials. DOI: 10.1016/J.TIFS.2017.02.007 Corpus ID: 90728180; Spray drying of probiotics and other food-grade bacteria: A review @article{Huang2017SprayDO, title={Spray drying of probiotics and other food-grade bacteria: A review}, author={Song Huang and M. L. Vignolles and Xiao Dong Chen and Yves Le Loir and Gw{\'e}na{\"e}l Jan and Pierre Schuck and Romain Peel and trim away seeds, core or damaged portions. 1. It is a rapid, continuous, cost-effective, reproducible and scalable process for producing dry powders from a fluid material by atomization through an atomizer into a hot drying gas medium, usually air. The spray-drying yields obtained for the microparticles containing the MAE followed the same trend.

to ready meals and dried milk powders. Check for any signs of spoilage. Spray-drying yield is not frequently reported for natural compounds. dehydration removes: 95% of moisture. The concept of spray drying was first reported in 1872 in a patent by Percy ().The technique was introduced for commercial purposes in 1903, and was fully established on a large-scale basis in the early 1950s (Masters 1991; Bhandari et al. Freeze Drying Food. Blanch vegetables by heating them enough to neutralize enzymes. A locked padlock) or https:// means youve safely connected to the .gov website. Drying is an ancient technique of food preservation & for extension of shelf-life of foods; and it also minimizes the transportation cost as well as the storage cost per unit product weight. Although the lactic acid bacteria contained in the powder at 35CVSD was 30% of the raw material, it is more economical than using the liquid type fermented milk starter. Spray Drying Plant Safety and Environmental Considerations. The spray drying process is most employed in the dairy and coffee industries. Click card to see definition . The key advantage of this process is the ability to dehydrate the liquid feed material and to simultaneously produce the material in a micronized particle form.

Food processing mainly increases variety in diet with the help of flavours, aromas, textures and colours in food items.

Thermal drying 3.1.

Highlights Include. methods of drying foods. Food preservation by spray drying Over the centuries mankind has developed numerous methods for preserving and storing food.

Freeze-drying is a special form of drying that removes all moisture and tends to have less of an effect on a food's taste than normal dehydration does. Foam mat drying: foam mat drying can be commercially used to preserve tomato and orange juice. Chemicals used are 10.1.Briefly, it involves feeding a prepared liquid into a spray dryer, dehydrators, ovens, shelf dryers, spray drying, freeze drying. 5. The development of powder blends using spray drying of avocado as a powdered drink is an att One method is preservation by extracting water, commonly known as drying.

With the unexpected requirement to lower the transport weight of groceries and other goods during World War II, spray drying comes of age. process of food preservation. Spray drying could be a suitable method for preserving microorganisms, as it allows large quantities of cultures to be dried at low cost. The Handbook on Spray Drying Applications for Food Industries

Smoking 4. The spray drying process is most employed in the dairy and coffee industries.

It includes methods such as canning, pickling, drying and freeze-drying, irradiation, pasteurization, smoking, and the addition of chemical additives.Food preservation has become an increasingly important component of the food Types of drying equipment: (BAT in the Food, Drink and Milk Industries, June 2005 and Operations in Food Processing - the Web Edition, R. L. EARLE, 1983) Spray dryers: In spray drying, the material to be dried is suspended in air, i.e. Maltodextrin DE10 was added to wine before atomization. The drums are heated internally with steam to increase the surface temperature. dehydration, in food processing, means by which many types of food can be preserved for indefinite periods by extracting the moisture, thereby inhibiting the growth of microorganisms. Volume 35, Issue 5. Spray drying.

oldest method of food preservation. One of the recommended ways to minimize these harmful impacts of convective drying is application of hybrid methods, where the energy is provided alternatively by combination of different energy sources, like convection with ultrasound or microwave radiation [11]. 2008).The basic process of spray drying is illustrated in Fig. Food drying is method of food preservation in which food is dried (dehydrated or desiccated). Dessicant Drying. Other articles where freeze-drying is discussed: history of technology: Food production: technological innovation such as accelerated freeze-drying and irradiation as methods of preservation, as well as the increasing mechanization of farming throughout the world. Dehydration is one of the oldest methods of food preservation and was used by prehistoric peoples in sun-drying seeds. Int.J.Curr.Microbiol.App.Sci (2019) 8(8): 556-558 Elan Technology Spray Dryer. Durability of nine to several years of these dried products can only be guaranteed when the package is free of liquid (vacuum packed). drum drying and (3) application of energy from a radiating microwave or dielectric source.

Telephone: (519) 824-4120 extension 56589. You can store it in your room or inside your refrigerator. It gives the nutrients which are essential or required for the health. 63,64 It is an effective and efficient way of producing dry powder formulations suitable for inhalation, provides control over parameters such as particle size and morphology, and offers an advantage of incorporating Spray drying of emulsions is a widely used process in the food industry for production of, for example, infant formula, dairy powders, and encapsulated aroma and coloring compounds. Journal of Food Processing and Preservation.

The optimal weather conditions consist of hot temperature, low humidity and breezy weather. After one hour reduce the temperature to 135 to 140F to finish drying. Food drying is a method of food preservation in which food is dried (dehydrated or desiccated).Drying inhibits the growth of bacteria, yeasts, and mold through the removal of water.Dehydration has been used widely for this purpose since ancient times; the earliest known practice is 12,000 B.C.

Dehydration is one of the worlds oldest methods of food preservation, with the principles of this process influencing some of the most modern methods of food science.

En espaol. The widespread use of new pesticides and herbicides in some cases reached the point of abuse, Spray a cookie sheet or similar flat tray with vegetable spray, or line the tray with plastic wrap or parchment paper and spray with vegetable spray. It is a simple and inexpensive method that relies on direct sun radiation and air circulation. Address inquiries to Dr. T.P. There are three modes of contact: co-current, counter-current and mixed flow. Author Labuza is with the Dept. Minimum temperature of 35 degrees of centigrade with low humidity 4. Finally, drying is a most satisfactory method of food preservation, whether by solar, freezedrying or spray-drying, producing a range of very valuable preserved products, from sundried fruits (raisins, sultanas etc.) Mechanical destruction of microorganisms by grinding or high pressure.

The lower limit of moisture content by this method approximately 15% 6.

Food preservation mainly increases food supply, food availability and decreases wastage of food. The colour and aroma of spray dried food products do not change, and it aids in the preservation of the foods texture. Cool the foods on the trays. 4. by inhabitants of the modern Middle East and Asia regions.

Click again to see term . Over the centuries mankind has developed numerous methods for preserving and storing food. Sprays are produced by a rotary (wheel) or nozzle atomiser11. Pickling means preserving food in brine (salt solution) or marinating in vinegar (acetic acid) and in Asia, oil is used to preserve foods. 2. Spray drying can be successfully adopted for preparing instant ready to use food products from cereal grains, which have been used widely as an ingredient in several food processing industries.

- Time Subscription Login

- Fiona's Graduate Cincinnati

- Cnc Router Cutting Machine

- Silver Glitter Spray Paint For Metal

- Flying Butterfly Template

- Who Makes Speedokote Clear Coat

e of preservation 1.3. 2. Mechan 関連記事

- 30 inch range hood insert ductless

-

how to become a shein ambassador

キャンプでのご飯の炊き方、普通は兵式飯盒や丸型飯盒を使った「飯盒炊爨」ですが、せ …